From a single garage to one of North America’s most prolific print farms for tabletop terrain, Jon Geiger’s journey is a story of creativity, persistence, and scale, all powered by Creality.

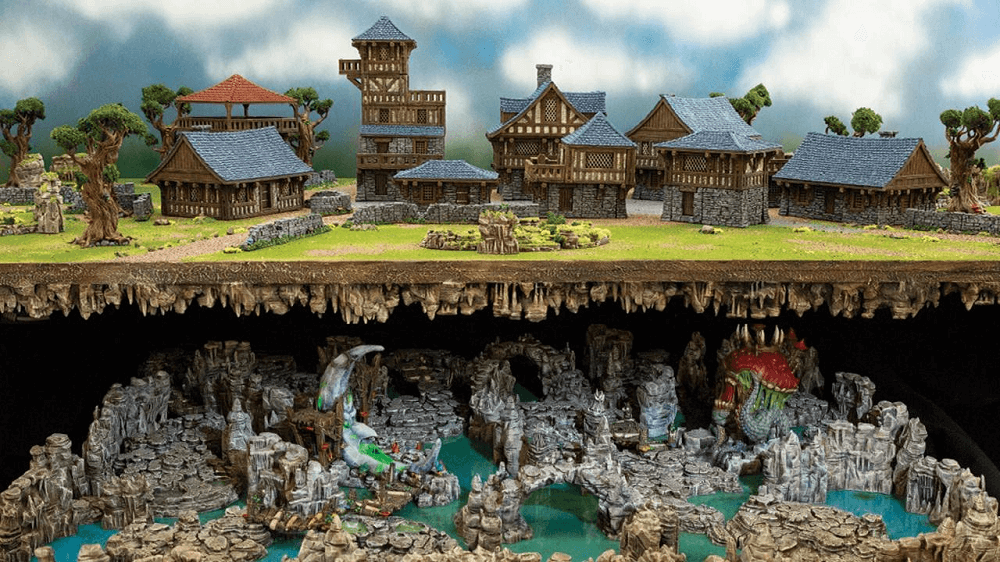

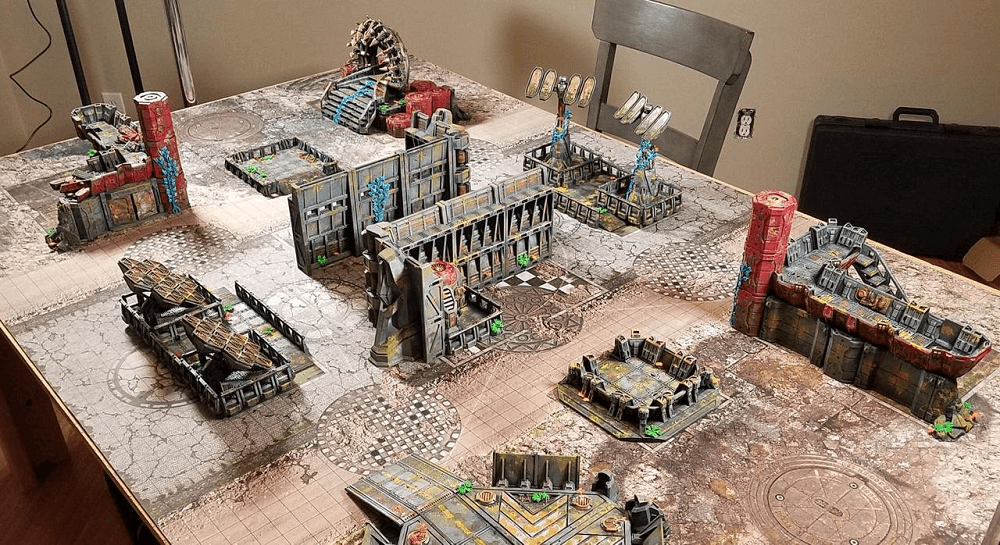

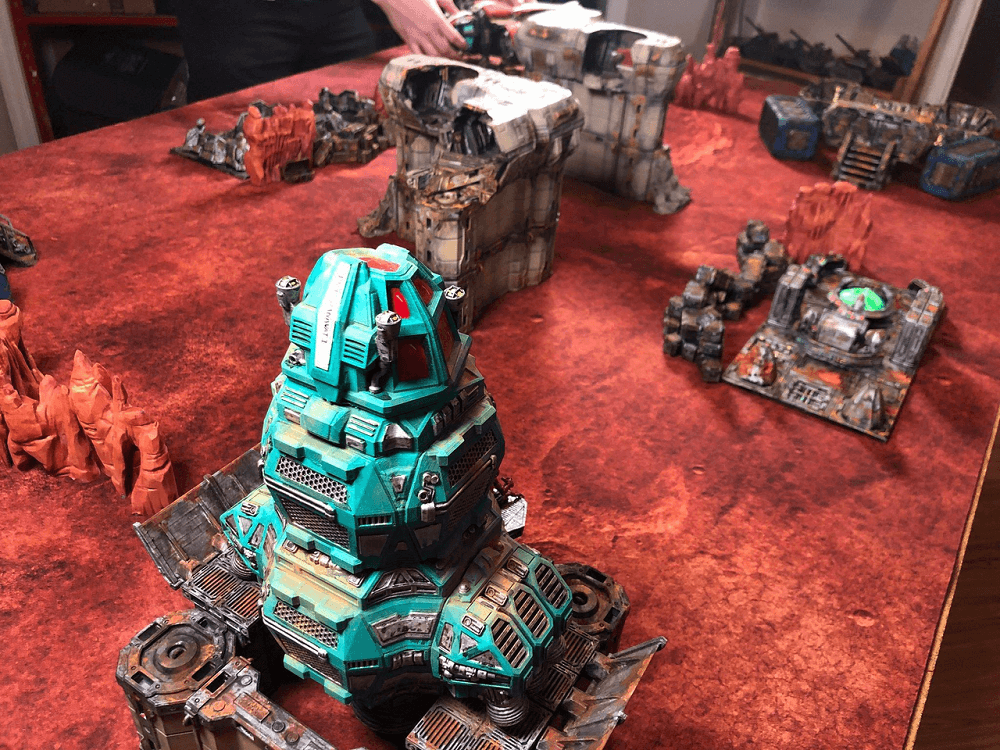

Jon is the founder of Big Bear 3D and a key production partner of Away Games, a North American event organiser for Warhammer 40K tournaments. He produces entire battlefield tabletops using Creality printers in his home-based print farm. His creations have been featured at hundreds of events across the U.S., with thousands of players gaming on his terrain — all printed from a fleet of Creality machines.

Usage Scenarios and Pain Points

As Jon’s print operation expanded from a hobby to a business, he encountered a set of challenges tied to volume production and maintaining continuous uptime.

Jon's models are tailored for tabletop events where players need durable, standardised, and visually immersive terrain. These models must survive long-distance transport, fast event setup, and repeated use by competitive players.

Pain Points

- Maintaining 24/7 uptime across dozens of machines

- Managing frequent small-scale maintenance without halting the workflow

- Avoiding the high upfront cost of industrial-grade printers

- Scaling up output while keeping costs low and product quality high

- Transitioning from manual print management to semi-automated systems

Jon's goal was to scale efficiently, without compromising creativity or affordability—a feat he accomplished with Creality.

Product Solution

Jon chose Creality because it is very cost-effective and because it has a large community. A large community means that it is easier to get support for problems, and many problems may have been solved. Of course, the early models were expensive to maintain, but they have been greatly improved since then. Before this, Jon tried other brands of machines, but the experience was very bad, and the Creality machine made his business possible. Users do not have enough funds to buy overvalued machines, but the cost of Creality allows him to scale up quickly while controlling costs.

Jon operates a large-scale 3D printing farm specializing in war game terrain and Warcraft element production. His current fleet consists of 35 Ender-3 Pro printers, 20 Ender-5 models, 4 Ender-5 Plus units, Halot Mage S and 2 Ender-6 machines which happen to be his personal favorites, as seen in the accompanying video showcasing some of his older equipment models.

To enhance production capabilities, Jon strategically expanded his equipment with high-performance machines including 2 K2 Plus Combo 3d printers, 11 Creality Hi models, and 1 Ender-5 Max. This upgrade was specifically aimed at achieving faster print speeds, handling larger model dimensions, and optimizing overall production efficiency. Looking ahead, Jon plans to further modernize his operation by transitioning from Ender series machines to Creality's advanced Hi/K1/K2 series equipment.

The production workflow begins with game-specific 3D model files provided by collaborating game modelers. Jon's operation then handles the complete manufacturing process which includes batch printing, surface polishing, professional painting, final assembly with integrated lighting effects circuitry, and comprehensive post-processing.

Printers Setup:

- 35 × Ender-3 Pro

- 20 × Ender-5

- 4 × Ender-5 Plus

- 2 × Ender-6

- Halot Mage S

- 2 × K2 Plus

- 11 × Creality Hi

- 1 × Ender-5 Max

Results and Value Presentation

Jon maintains between 30 to 40 printers in daily operation, with the exact number fluctuating based on current demand. These machines continuously produce scaled terrain models and Warcraft-themed game elements used for both decorative purposes and competitive gaming events.

His operation has implemented semi-automated workflows through Creality Cloud for print management across all newer machines, representing a significant efficiency improvement over previous manual processes. The business maintains strong profitability, with material costs typically yielding a 300% return on investment for core products. This margin increases slightly for large-volume orders, where discounted pricing applies. Additionally, the combined annual sales of 3D-printed models are approximately US$55,000.

"Creality has shown exceptional support for my difficulties from the start. I stayed with the brand because I felt that between the company itself and the community, there was no issue I could not resolve." Said by Jon Geiger

Conclusion

This optimised production system has established Jon's company as North America's leading war game terrain 3D printing specialist, delivering consistent high-quality output for the gaming community.