For those looking to simplify the manufacturing process, 3D printing has revolutionized production. What would have taken days in the past can now be accomplished in a quarter of the time. No longer are businesses, product designers, and manufacturers reliant on costly, inflexible processes; with 3D printing, the sky truly is the limit. But, for many enterprises, one 3D printer isn't enough to keep up with production, let alone offer the ability to scale in the future. That's where a 3D printer farm comes in. With a 3D print farm, businesses of all sizes can rapidly increase production without the enormous overhead that comes with traditional manufacturing. It offers unmatched flexibility, speed, and efficiency, making it easy to scale your business and bridge the gap between prototyping and production.

What is a 3D Print Farm?

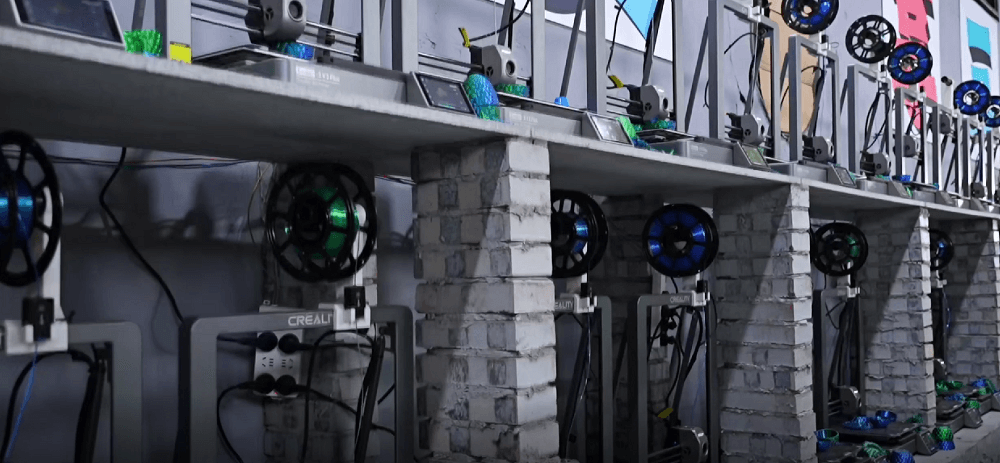

A 3D print farm involves multiple 3D printers operating together in a centralized setup. Think of it like your own personal manufacturing line that effortlessly creates prototypes, handles batch productions, and constructs custom prints at scale. With a 3D printer farm, production efficiency skyrockets, making it a powerful tool for industrial designers, schools, engineers, and entrepreneurs. What aspects of a 3D print farm make it so transformative?

Parallelized Printing

3D print farms allow for the simultaneous creation of products or parts, increasing production volume and allowing for faster turnaround times. They're easily scalable, offering the flexibility to add or remove printers to meet production capacity.

Remote Control

Having remote control over your 3D print farm is a game-changer. You can monitor and manage production using an internet connection from anywhere in the world. With the touch of a button, you can watch the printing progress, pause and resume prints, and cancel projects, all from your smartphone or computer. You can also monitor the progress through a live video feed, share and store 3D models on cloud-based platforms, collaborate with others, and even detect potential issues like underextrusion or warping.

Automation

Automation is another huge benefit 3D print farms offer, significantly reducing manual downtime and labor for 24/7 operations. By leveraging advanced software, you can automate tasks like maintenance, part removal, print bed management, printer assignment, and print job queuing.

As you can see, a 3D printer farm offers many benefits for a wide range of industries, allowing for enhanced creativity, greater efficiency, and unmatched freedom and flexibility.

How Does a 3D Printer Farm Work?

3D printer farms are a network of 3D printers that work simultaneously under a centralized control station. They're managed through specialized software like Creality Print, or custom dashboards, allowing for a seamless printing experience. What does the process look like in action?

Model prep → slicing → distributed print commands → monitoring → post-processing.

Let's break down each step into more detail.

Model Prep

The first step of the manufacturing process in a 3D print farm is model prep, and it's arguably the most important. To start, a model is created using a 3D modeling software or is sourced from a platform with pre-designed models. A benefit of using a modeling software is its ability to check for potential issues with the print, like unsupported structures, thin walls, and overhangs.

Slicing

The next step is slicing, where the 3D model is converted into instructions for the 3D printers to follow. This process involves preparing numerous models to print simultaneously and optimizing the settings for each batch or model.

Distributed Print Commands

Once slicing is complete, it's time to distribute the print commands across all printers. To do this, use the specialized 3D print farm software stated above. After you upload the 3D design file into the software platform, you can manage numerous tasks like scaling, assigning jobs to specific printers, orienting, and more.

Monitoring

Once the manufacturing of the prints begins, it's important to monitor the progress of all printers within the 3D printer farm. This process involves tracking the printers' status and printing processes and watching for potential problems as they arise.

Post-Processing

Once the prints are complete, the post-processing procedure begins. This step can include adding features, applying coatings, smoothing surfaces, and removing supports. The actual processes depend on the printing software and technology you use, along with the materials and your desired final products.

Utilizing a 3D printer farm allows for high throughput, low manpower, and greater scalability, allowing users to incorporate 5 to 500+ printers simultaneously.

Best Printers for a 3D Print Farm

Your 3D printer farm is only as good as the 3D printers you use, so it's essential to choose the right ones to fit your needs. We've created a list of the best print farm printers for a variety of uses and outlined them below.

FDM Printers

FDM or fused deposition modeling printers extrude melted thermoplastic filament layers to build objects. Models like K2 Plus Combo, K1 Max, and the Ender Series are extremely popular in prototyping environments, schools, and the consumer market. What makes these 3D printers stand out?

-

Budget-friendly

-

Great for beginners

-

Reliable for continuous print jobs

-

Ideal for PLA, PETG, and TPU filaments

-

Excellent for creating functional parts

-

Premium features, including auto-leveling and resume printing

-

The included filament sensors are 3D print farm essentials

Resin Printers

Resin printers, also called digital light processing or DLP printers, selectively cure a liquid resin using a light source, creating layers that result in a 3D object. These 3D printers are known for creating exceptional high-resolutions, making them a popular choice for detailed miniatures, jewelry, and prototyping. Although they need more post-processing and ventilation setup in the 3D printer farm environment, resin printers can create precision details beyond the abilities of FDM printers. Models like Creality Halot-Mage and Halot-One offer higher build volumes without sacrificing precision or intricacy. Why are resin printers a great option for high-performance 3D printing?

-

Higher precision for small, detailed prints

-

Smoother surface finish

-

Isotropic part properties for uniformity throughout the curing process

-

Complex design capability

-

Wide variety of resins

-

Ideal for jewelry, miniatures, prototyping, and more

Why Start a 3D Print Farm Business

The rising demand for personalized, on-demand production creates a unique opportunity for those looking for an exciting business venture. A 3D print farm business offers virtually unlimited opportunities for growth and creativity, making it an intriguing option for those willing to think outside the box. Thanks to the affordability of 3D printers, opening a 3D print farm business boasts lower entry barriers than traditional manufacturing alternatives. Some common business ventures include:

-

Custom products for Etsy or online stores

-

Prototyping services for startups

-

Outsourced printing for industrial or medical clients

-

Resin miniatures, cosplay props, and functional parts

How to Launch Your Own 3D Print Farm

If you're ready to start your own 3D print farm business, knowing how to start is often the hardest part. We've created this quick-start guide that you can use to get your business up and running quickly.

-

Purchase your equipment - To create a 3D printer farm, you'll want to start with 5 to 10 Creality K1 or Ender-3 V3 units.

-

Decide on a location - Choose a location to set up your 3D printers that has proper ventilation, like a garage or office space.

-

Choose a software - Choose a software that best aligns with your manufacturing goals. Quality options include Creality Print, OctoPrint, Klipper, and APIs.

-

Allot a post-production station - Having a designated post-production station is key to ensuring your prints stay safe. Make sure it offers room for sanding, curing, and quality control.

-

Pick a sales channel - Pick where you plan to sell your prints. Popular platforms include Etsy, Shopify, B2B websites, and social media marketing.

Looking for a 3D Print Farm Near You?

If you're not ready to build your own 3D printer farm, you can look for some in your area. Many people simply search for "3D print farm near me" on Google, but that's not the only method. Platforms like Treatstock and Craftcloud can connect you with a nearby location, or you can visit local maker spaces or FabLabs, which offer 3D printing at scale.

Pros and Challenges of 3D Printer Farms

Before opening your own 3D printer farm business, it's important to understand their pros and challenges.

Pros

-

Mass customization and manufacturing

-

Scalable and modular - start small and grow big

-

More cost-effective for low-volume production compared to injection molding

-

Easy automation with minimal labor

Challenges

-

Maintenance and calibration across machines can be challenging for beginners

-

Post-processing can be labor-intensive

-

Adequate space to store materials is needed

-

Environment control during printing is essential, especially with resin printers

Conclusion: Is a 3D Print Farm Right for You?

The 3D printing farm model is shaping the future of decentralized manufacturing, one layer at a time. Whether you're a maker, entrepreneur, or industrial designer, a 3D printer farm is a flexible, scalable solution for all your manufacturing needs. Choosing the right printers is the key to success and ensures you create top-quality prints. Creality offers reliable, high-speed printers that make it easy to build an efficient print farm on a budget. Discover the freedom, flexibility, and scalability of 3D printing with the power of Creality.