In an industry where tradition often overshadows innovation, Sydney-based fashion label AMISS is carving its own different path - partnered with Creality, a global leader in 3D printing technology, to prove that additive manufacturing isn’t just a tool—it’s a catalyst for reimagining design, sustainability, and creative freedom.

Amiss's Debut at Wings Independent Fashion Festival

Their groundbreaking collaboration, showcased at the WINGS 2025 Independent Fashion Festival, marks a pivotal shift in how technology empowers designers to break physical and conceptual boundaries.

From Concept to Catwalk in Days: A New Solution for Fashion’s Silent Struggles

Vanessa and Josh, co-founders of Amiss

Vanessa and Josh, co-founders of Amiss

Founded by siblings Vanessa and Josh, AMISS was born as a personal exploration of identity, culture, and style. Their debut collection, showcased at the WINGS Independent Fashion Festival in Sydney, embodied a surrealist vision inspired by natural concepts and organic textures - seashells, Australian bushlands, and the eco-utopian of solar punk.

“As a small brand, we don’t have time or money to waste,” Vanessa explains. “Creality let us move fast, test ideas, and actually produce what we envision—without compromise.”

In the Fashion industry, a typical prototype development cycle can take months. By replacing traditional sculpting and textile-cutting methods with Creality‘s complete 3D-printing solutions, the designers compressed months of prototyping into days while achieving unprecedented creative control at a lower cost. Creality’s accessible ecosystem—scanners, printers, laser cutters, and filaments—enables studio-scale production of runway pieces, from 3D-printed accessories to laser-engraved biodegradable textiles.

Tech-Powered Workflow: Scan, Model, Print, Cut — All in One Studio

3D-printed Seashell Bag in Amiss‘s Debut Collection

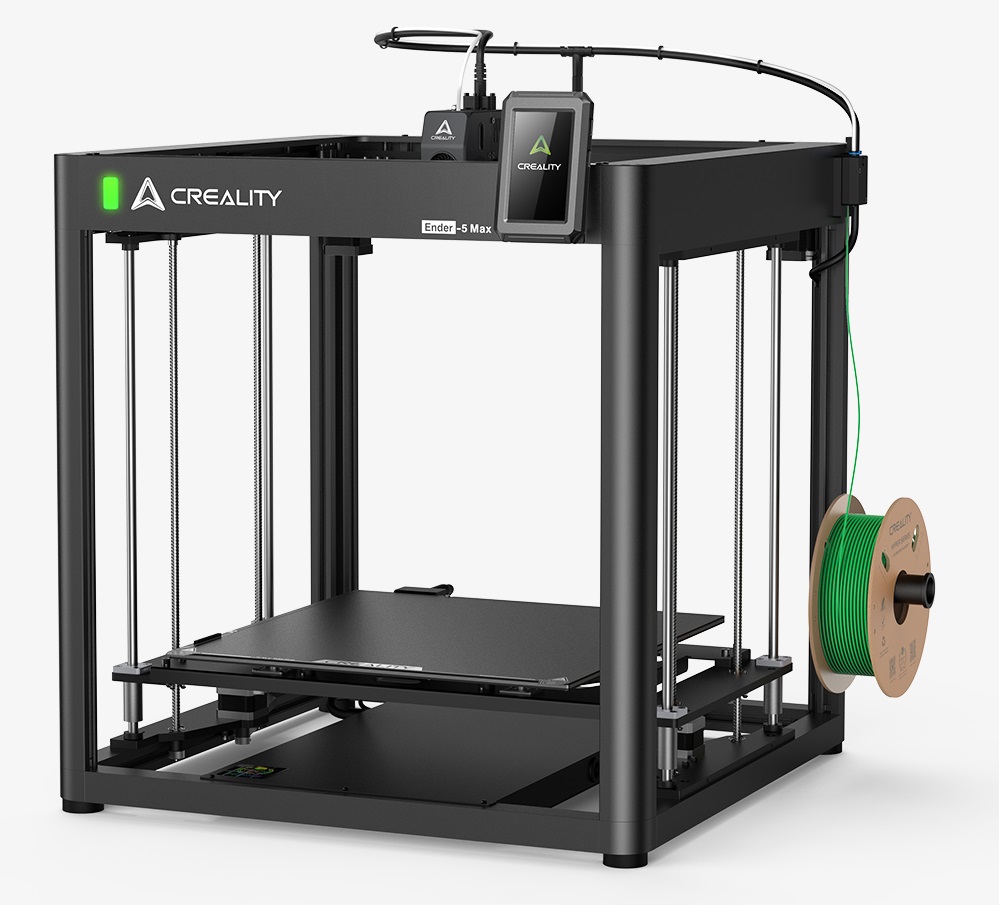

For AMISS, technology is the backbone of their creative process. In their studio, with Creality’s complete 3D-printing solutions, the journey from nature concept to runway happens in hours, not weeks. Using the Otter Lite 3D scanner, the team captures inspiration directly from nature—scanning shells and organic forms from the Australian bush and Sri Lankan coastline. These detailed scans are transformed into CAD models, which are then printed using the K2 Plus. The corset worn by the model features a large volume and was produced using the Ender-5 Max large-format 3D printer.

With the all-around capabilities of 3D printing, the K2 Plus and Ender-5 Max empower them to produce multi-colour corsets, accessories, and structural elements—without relying on external manufacturers.

“What used to take weeks, we now do in under two hours,” says Josh. “We model it, print it, and hold a real-life prototype in our hands by the end of the afternoon.”

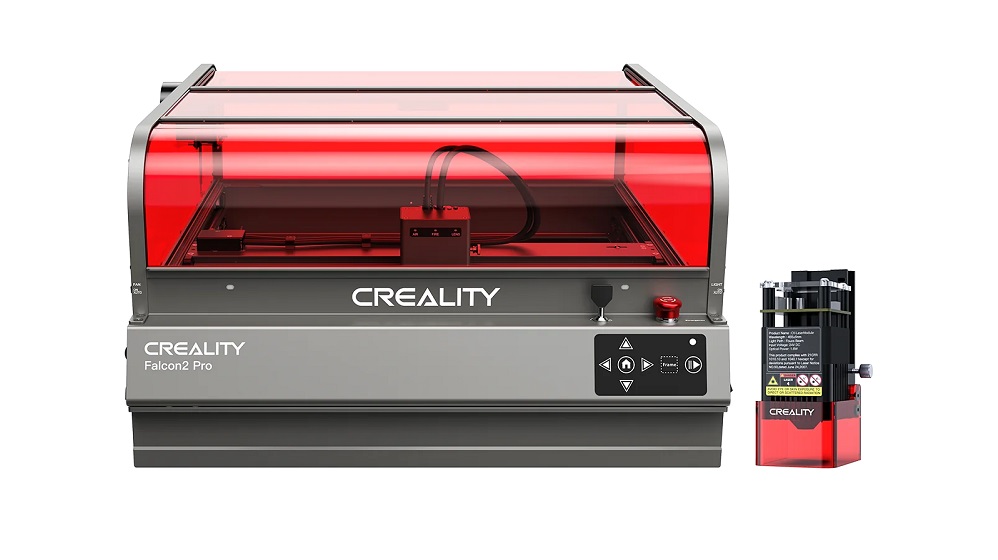

For finishing touches, the Falcon2 Pro 60W laser cutter lets them rapidly fabricate custom textiles and components, from surreal skirts to signature detailing. With high-power output, built-in safety, and plug-and-play simplicity, Creality’s complete 3D-printing solutions enable AMISS to move fast, create boldly, and maintain complete control over their production—all in-house.

Creality Technology in Action

K2 Plus Combo: A total package of 3D printer with synchronised high‑precision multi‑colour 3D printing, transforming every idea of the designer into a real‑life model.

https://www.creality.com/products/creality-k2-plus-cfs-combo

Ender-5 Max: Featuring a large-format 400×400×400 mm build volume, Ender-5 Max is capable of printing life-size and oversized models effortlessly.

https://www.creality.com/products/creality-ender-5-max

Otter Lite: Ultra‑precise 0.05 mm scanning with high‑speed performance and wireless portability, turning real‑world inspiration into digital creation, anytime, anywhere.

https://www.creality.com/products/creality-cr-scan-otter-lite-3d-scanner

Falcon2 Pro: A powerful, precise, and safe laser engraver with adjustable output, a large workspace, and wide material compatibility—ideal for creative, educational, and commercial use.

https://www.creality.com/products/creality-falcon2-pro-60w

Soleyin & SpacePi X4:

- Soleyin Filament: High‑quality PLA with stable, vibrant colour palette; excellent layer adhesion for sharp details and smooth matte finishes.

https://www.creality.com/products/creality-filament-resin

- SpacePi X4 Filament Dryer: Dual‑chamber, smart humidity control up to 85 °C—prevents moisture-related printing issues and ensures consistent, reliable output.

https://www.creality.com/products/creality-spacepi-x4

Empowering the Next Generation of Fashion Makers

As fashion designers like AMISS continue to merge natural inspiration with cutting-edge technology, they’re not just redefining fashion—they're carving a new path for a more sustainable, imaginative, and inclusive creative future. With Creality’s tools that do more than speed up prototyping, Fashion Makers are gaining the power to bring their visions to life. By empowering the next generation of Makers, Creality is igniting new possibilities and expanding the boundaries of innovation and creativity.

Explore the full behind-the-scenes story at: