3D Printing Industry reviews the Creality Sermoon V1 Pro 3D printer.

Founded in 2014, Creality has made a name for itself in the FFF 3D printing world with its suite of extrusion-based machines making the technology accessible to a much wider group. The Shenzhen-based Chinese company offers a wide and varied range of FFF 3D printers, DLP, plus 3D scanners and laser engravers.

Creality’s flagship product line is the Ender 3D printer series, which includes the older and exceedingly well-known Ender 3 and the newer Ender 3 S1 Plus. In the CR series, a range offering larger and more powerful printers, we find the CR-10 Smart Pro, a new version of their iconic CR-10 model.

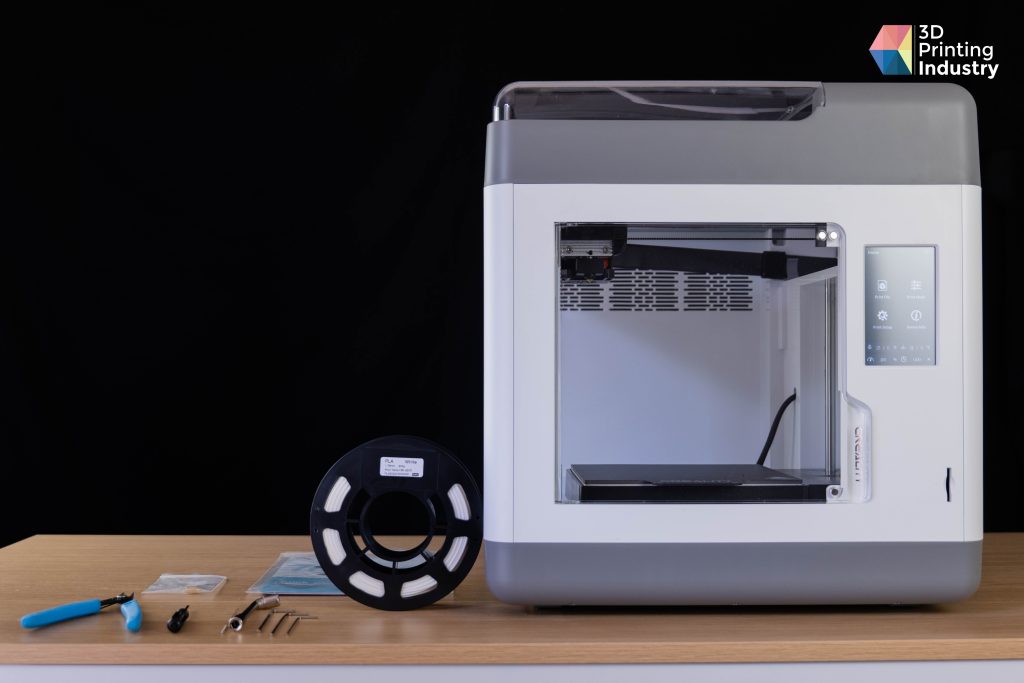

As a mid-range offering, the Sermoon V1 Pro combines a simple extrusion configuration, a fully enclosed build volume, and an ecosystem that makes it easy and fun for even the most novice to learn about the technology.

Priced at $539 for the Pro version, and $419 for the standard, the printer is designed for desktop and educational use and allows users to print with a wide variety of filaments. Materials include the basics such as PLA and ABS and flexible materials such as TPU.

The Creality Sermoon V1 Pro. Photo by 3D Printing Industry.

A print-out-of-box 3D printer

Featuring an all-metal chassis, the Sermoon V1 Pro is based on a Cartesian axis system, a method known to be more rigid and more accurate yet slower than a delta or CoreXY system. The enclosed construction chamber measures 175 x 175 x 165 mm. A closed chamber allows 3D printing of complex filaments such as ABS, for example, a filament with high internal stresses during printing. This is crucial for high-temperature materials as it avoids the problems of deformation and delamination that can occur due to cold air-induced shrinkage of parts.

The removable print bed is magnetic and flexible, making it easy to remove the parts once printed. After 235 hours of printing, we observed the adhesive film on the surface of the build plate remained strong and relatively durable.

On the electronics side, connectivity options include Wi-Fi and an SD card reader. However, Wi-Fi could be improved to permit the direct sending of files from the Creality slicer rather than via the Creality cloud. However, Creality has developed a new software called “Creality Print” which allows the user to directly transfer the printed files to the 3D printer via a Wi-Fi network and print the model.

The functions of the Creality Cloud app application are as follows: after connecting to Creality Cloud via WiFi, you can directly select the model, slice it and print it in the app. The printing process can then be controlled remotely on the mobile phone.

Users have a 4.3-inch color touchscreen on the front, which is used to calibrate the bed, load filament, and start printing. After use, the user interface is intuitive and easy to use, and we didn’t encounter any bugs or lags, greatly enhancing our experience.

A versatile printer to unlock creativity

Where the Sermoon V1 Pro stands out from its competitors is its precision and repeatability, plus capabilities to print straight out of the box. There is no need for the user to do any assembly or mounting. Once the printer is unpacked and calibrated, the user simply prints the model of their choice.

This 3D printer is distinguished by the versatility of its print head, which is fully detachable for quick tool head changes, with a maximum nozzle temperature of 245°C. The system’s printhead houses a direct drive extruder, meaning that the motors that deliver filament to the nozzle are mounted directly on the printhead.

However, while Creality claims to have an automatic bed leveling system, this is a stretch. The user must perform bed leveling with a piece of paper to have the nozzle scrape slightly while adjusting the bed. Nowadays, almost all printers have an automatic leveling system, and it would have been the preferred option to have such a feature, especially since this printer is designed for beginners. The rest of the 3D printer includes two fans, one to cool the filament once it has been extruded onto the part, the other to cool the hotend.

The Sermoon V1 has an external spool holder. Depending on the filament you want to print, you would need a third-party device to keep your filaments dry. We were impressed with the user experience of the Sermoon V1’s firmware and software and had no complaints, although adding a feature to allow files to be sent via Wi-Fi without going through the Cloud could be helpful.

The Sermoon V1 Pro calibration process

The Sermoon V1 doesn’t have an automatic bed leveling function, which is a shame as it makes for a smoother user experience. Leveling involves assessing five points on the bed and adjusting bed height via the touch screen. The user is looking for that slight friction between the nozzle and the piece of paper between the bed. This method works well for someone experienced with 3D printers but will likely be more problematic for a beginner.

Even if this method is common on older machines and does not pose a problem, today, we would have liked to see an automatic leveling system. With these five points, the printer creates a mesh and determines the relative position of the printing platform and the XY plane. The machine can compensate in real-time by raising or lowering the Z-axis during printing. Even if the printing platform has a certain angle of inclination, printing can also be done by compensation.

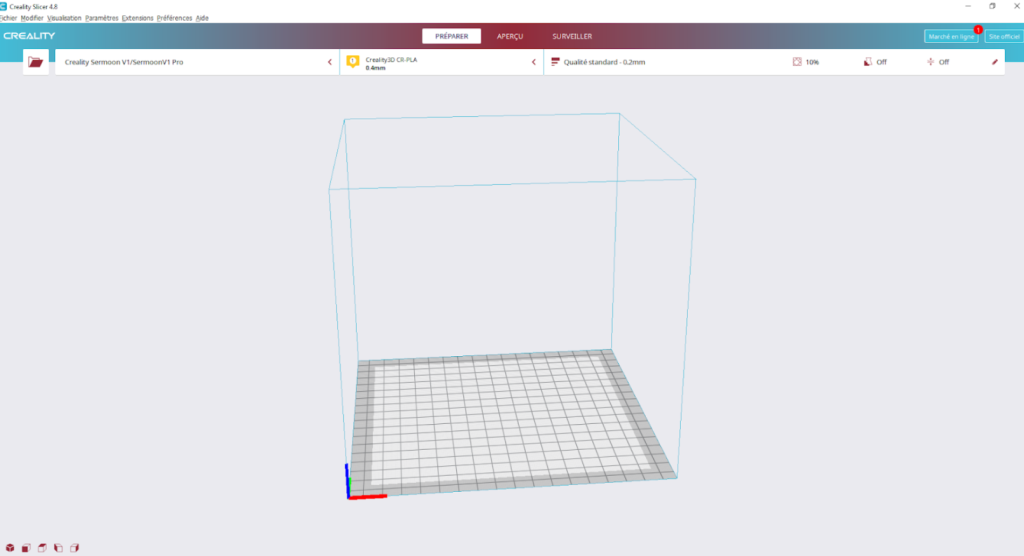

Creality Slicer

Much like Creality’s other systems, the Sermoon V1 uses a reskinned version of the open-source Cura slicer. The software operates very similarly to most FFF slicers on the market, with basic translation, rotation, and rescaling functionality. It is easy to pick up after a few minutes of fiddling around in the menus. Creality Slicer, based on Cura 4.8.2, also has some interesting features like ironing, material flow rate compensation, and even a vase mode.

Unlike many of the competitors with whom we found some problems and occasional laggy menus with rebadged versions of Cura, the Creality software, as a whole, works as expected and gets the job done. This printer has pre-configured profiles directly in the slicer for many filament brands and materials, including PLA, PETG, ABS, and TPU. However, it is possible to develop any profile to print any material that requires a print temperature below 245°C.

Once the calibration was complete, we found the 3D printing step to be very intuitive. When the G-code is ready, the user can either plug an SD card containing the file into the printer or send the file directly via the Creality Cloud between the computer and the printer.

Creality Slicer UI. Image by 3D Printing Industry.

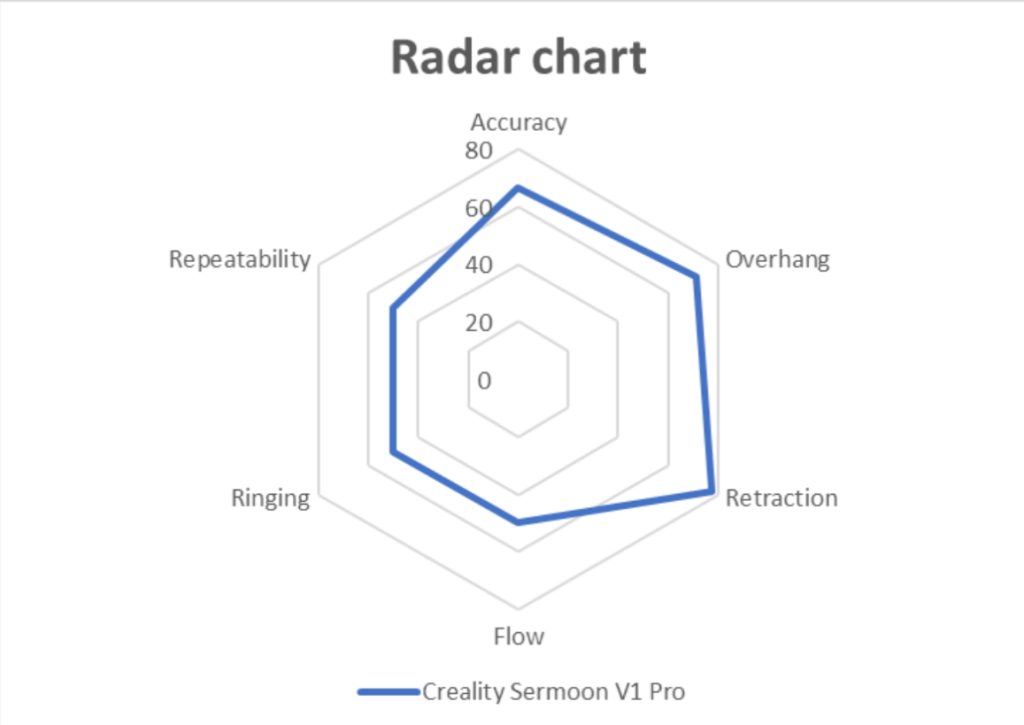

Benchmarking the Sermoon V1 Pro: 76/100

So, how did the Sermoon V1 Pro 3D printer perform in our benchmark tests?

We start with 3D Printing Industry’s own benchmarking model, which combines several of our smaller print tests into one comprehensive part. We usually print this test in PLA to compare results between printers, but we also often try a PETG or ABS variant to see how the machine handles more difficult filaments.

Having tested the Creality to its limits with PLA, we printed this reference model in PETG. This material is not significantly more complicated to print than PLA but is more prone to stringing. We give each individual section a weighted score based on factors such as dimensional accuracy, surface quality, and structural integrity. Impressively, the Sermoon V1 Pro received an overall score of 76/100 from 3D Printing Industry – a good quality 3D printer scores 60+.

The overhang portion of the test is designed to determine the angles at which the system can print without the use of support structures. The Sermoon V1 Pro came through with a limit of 50°, which is an excellent result for a printer in this price range.

Similarly, the bridging test is intended to determine the horizontal printing capabilities of a system. The Creality achieved the 35mm bridge length before the structures started to bend and warp – a respectable result. Thus, despite this print test, overhangs and bridges are still recommended to be printed with supports.

The retraction test, which assesses a printer’s ability to move from one area to another without extruding material, really shone. With materials like PETG, it’s not uncommon for even the best printers to struggle with this test. Still, the Sermoon V1 Pro made the entire spike matrix with almost no stringing and virtually no artifacts, resulting in one of the cleanest tests we’ve ever seen on PETG.

The printer particularly stood out on retraction, overhangs, and accuracy. However, we did notice some ringing on the X and Y sides. Ringing is a residual resonance when there is an abrupt change in trajectory, which implies slight deformation on the relevant faces.

3DPI benchmarking test results. Photos by 3D Printing Industry.

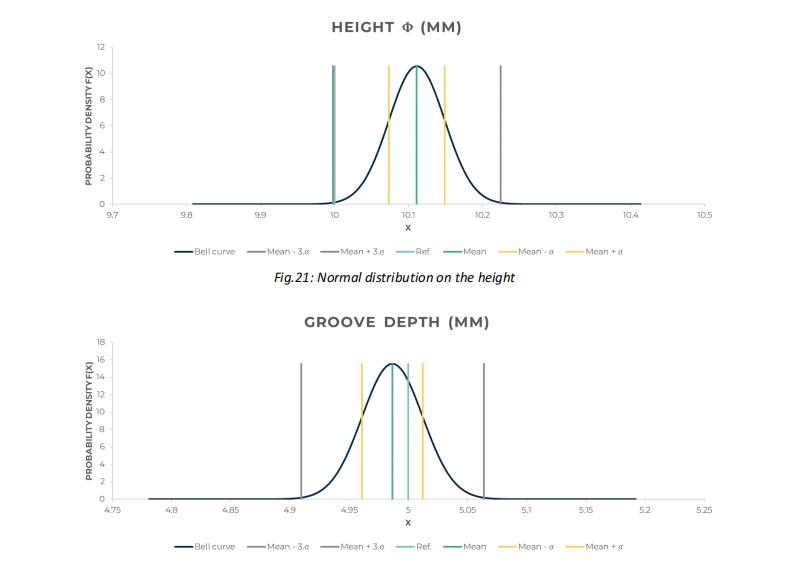

Next, we conducted a repeatability test to assess the printer’s capability to produce multiple parts with the same or very similar dimensions. By studying the normal distribution of the concentric circle’s diameters, we can say that the printer offers sufficient repeatability when the average deviation from the intended dimensions is under 0.1mm, and the standard deviation is under 0.05mm. Our measurement devices are accurate to ±0.015mm.

We printed parts in groups of three containing one square, one hexagon, and one tube model, and in terms of repeatability, the Sermoon performed better than the average in its price range. The mean difference for all dimensions was 0.0867mm, under the 0.1mm reference figure, while the standard deviation for all dimensions was 0.0351mm, under the 0.05 mm reference figure.

Although the printer provided a good repeatability result, we found that what brings the average down considerably is the height measurement. Indeed, with an average difference of 0.1359mm, we can clearly see the lack of accuracy on the Z-axis, where a sensor would have significantly reduced this gap.

Real application tests

Our final phase of testing the Creality Sermoon V1 Pro turns to real-world applications, or how you might want to use this 3D printer regularly.

We first printed this waterproof box. This model tests the Sermoon’s ability to combine several parts to create a more complex model, including a PLA box with a TPU98 seal. Without the need for post-processing, the printed part worked perfectly, and no defects or mismatches between layers were found during the printing process.

After observing very good results on the seal of the waterproof box, we decided to push the printing tests a little further with flexible filament. We then opted for a TPU85A filament, which is much more flexible and elastic than the previous one but also much more complicated to print. Thanks to the direct drive extruder, the result is more than honorable. We used a 120% flow rate to compensate for the fact that the extruder squashes this very elastic filament. The retraction was managed perfectly, and there were no visible defects on the part. The only flaw? The build plate is so efficient that we had trouble removing the parts. Due to their advanced elasticity, we deformed them slightly, but they remain usable.

We also printed an air duster with the same TPU. The result is just as impressive—zero defects with excellent print quality. We only had to cut off the top to get a fully usable model and super fun to print.