Even if you’re making an easy model or an intricate prototype, selecting the correct nozzles makes a huge difference. Today’s 3D printer nozzle guide clearly describes 3D printer nozzle size, material, and purposes, so you can choose the ideal one for your requirements.

What is a 3D Printer Nozzle?

Why Nozzle Choice Matters in 3D Printing?

Just like a fine pen tip brings out complex details, however, a wide tip covers up the area fast, so does the nozzle. A 3D printing nozzle impacts four major factors: speed, print quality, strength, and accuracy.

Print Quality & Precision

Print Speed

This is simple: Larger nozzles mean quicker prints. For instance, the biggest 3d printer nozzle, can squeeze out four times the amount of material every pass as a 0.4mm nozzle. This implies reduced passes to finish every coat, and it cuts hours off large prints.

Print Strength

This piece will surprise you: the bigger the nozzle, the stronger the print. Yes, it’s true. This is because they draw up broad lines of filament that blend best. Think of it like storing thick cords rather than thin threads, so more adhesion every layer to the next.

The big 3D printer nozzles are both quicker and more long-lasting. However, the thin lines from smaller nozzles can break effortlessly under pressure. Therefore, regarding durability over charm, go big.

Also, the link between extrusion width and layer height originates from the nozzle. Generally, the ultimate layer height values must not go beyond 80% of the diameter of the nozzle.

For instance, a 0.4mm nozzle possesses an approved ultimate layer height of 0.32 mm. Choosing the incorrect size can cause bad surface quality, hanging, or even nozzle blockages.

Common 3D Printer Nozzle Sizes & Materials

3D Printer Nozzle Sizes

-

0.2 mm Nozzle: A 0.2mm nozzle is best for printing prototypes with minute details. Typically, it’s utilized for jewelry, thin-walls, miniatures, and large-resolution creative items. But, 0.2mm nozzle settings boost print duration notably and are more vulnerable to clogs.

-

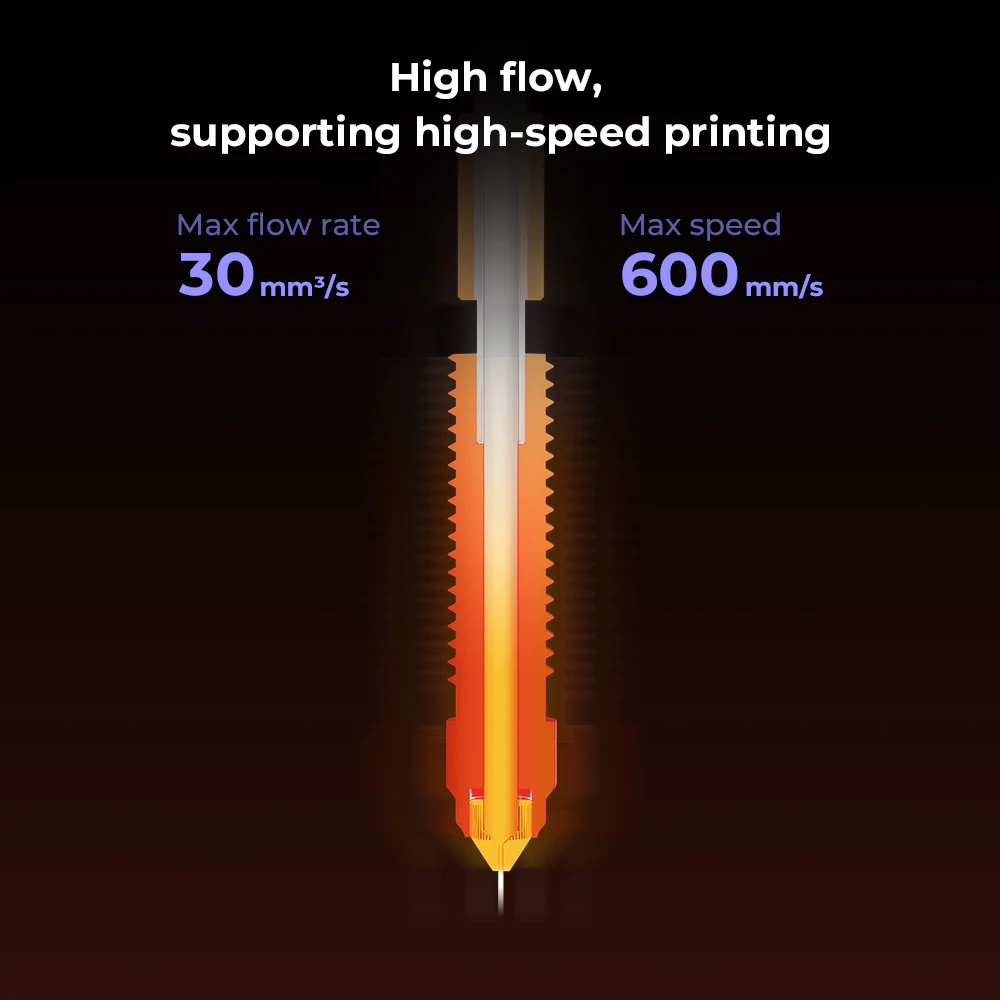

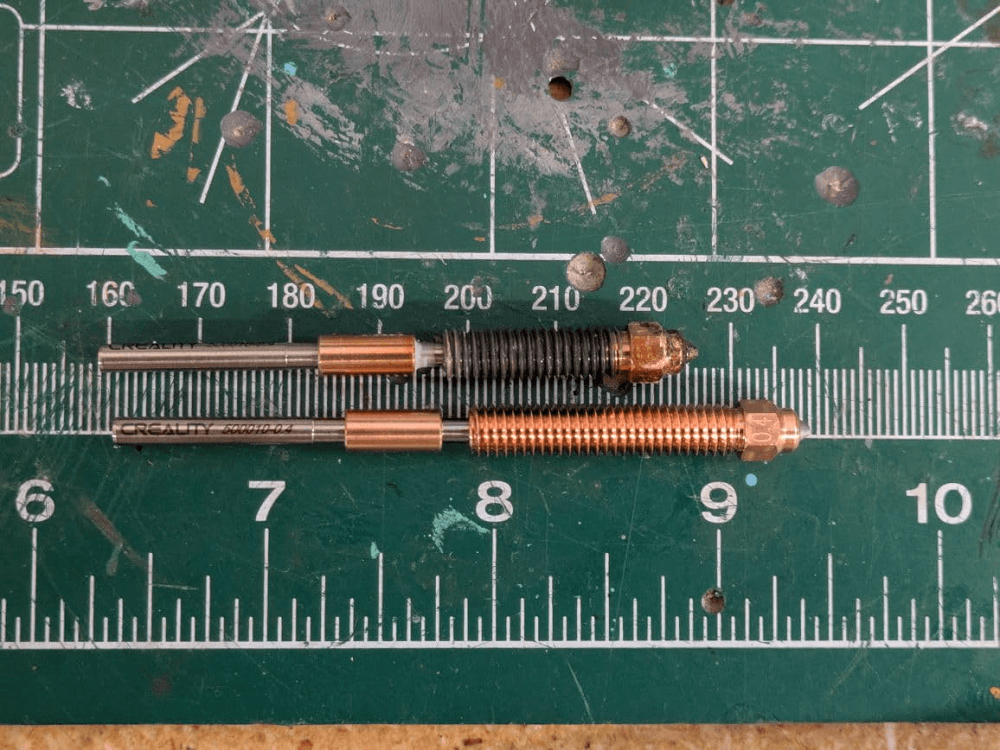

0.4mm Nozzle: The 0.4mm nozzle is the one-size-fits-all for the FDM 3d printers and appropriate for a range of printed components, like simple models to decorative prints. It brings a balance of pace and detail. That said, your printer also determines the real speed ability, as Creality Hi Combo comes with a mind-blowing print speed of 600mm/s.

-

0.6 mm Nozzle: Slightly broader than a normal nozzle, a 0.6mm nozzle is perfect for working parts that must be firm. It lowers the print duration as it can set down a big quantity of material instantly, and is unlikely to jam. This makes it perfect for hard materials such as TPU. It’s beneficial for prototyping.

-

0.8 mm Nozzle: A 0.8mm 3D printer nozzle size is utilized for printing big components and prototypes. Though the diameters of the nozzle can be as broad as 2mm, a 0.8 mm diameter provides notably quick printing at the same time, staying quite useful and user-friendly. Its thicker lines lead to powerful prints, however, with less detail.

-

1.0 mm Nozzle: Among the biggest 3D printer nozzle choices for electronic devices. With a fast printing speed, it’s perfectly suitable for big structural parts where detail doesn’t matter.

-

1.2 mm Nozzle: Mostly utilized in expert or industrial settings. It manages high-paced prints and massive objects, but is not suggested for small or detailed models.

| Nozzle Size | Best For |

| 0.2mm | Miniatures, Jewelry, fine detail prints |

| 0.4mm | All-purpose Use |

| 0.6mm | Stronger parts, faster prints |

| 0.8mm | Prototypes, large and thick layers |

| 1.0mm | Extra-large prints, high-speed builds |

| 1.2mm | Industrial applications, rough drafts |

Nozzle Materials

-

Brass Nozzle: Brass nozzle is the most popular nozzle material. It’s affordable and functions well with non-abrasive materials such as ABS and PLA.

-

Hardened Steel Nozzle: A few people are inclined to utilize hardened steel nozzles, as they’re immune to damage and more durable. Besides, they’re best nozzles for 3D printing with coarse filaments such as metal-fill, carbon fiber, and glowing materials. However, it can produce uneven internal surfaces, leading to bad prints.

-

Stainless Steel Nozzle: More strong compared to brass, stainless steel is non-corrosive and appropriate for making food-safe elements. Also, it manages abrasive materials somewhat better than brass.

-

Ruby-tipped Nozzle: The nozzles are a mix of steel or brass body with a ruby tip. These are long-lasting and sustain great accuracy, and are ideal for durable usage and exotic materials such as carbon fiber and metallic filaments.

-

Tungsten Carbide Nozzle: These 3D printing nozzles provide maximum longevity and constant extrusion. They’re robust, favorable for the two normal and abrasive materials.

-

Plated Copper Nozzle: Provides amazing heat conductivity, assists full temperature printing, and offers effortless extrusion.

| Nozzle Material | Best For |

|

Brass

|

PLA, ABS, basic filaments

|

| Hardened Steel | Carbon fiber, glow-in-the-dark, metal fill |

| Stainless Steel | Food-safe items, corrosion resistance |

| Ruby-tipped | Exotic and abrasive materials, High-durability |

| Tungsten Carbide | Extreme durability, consistent flow |

| Plated Copper | High heat conductivity, smooth extrusion |

How to Choose the Right Nozzle Size for Your Needs?

When and Why to Change Your Nozzle?

Common Signs You Need to Replace a Nozzle

-

Frequent nozzle blocakages

-

Prints with unstable or insufficient extrusion

-

Evident damage or bending on the tip

-

Lower print quality, specifically for minute details with a 0.2mm nozzle

Nozzle Maintenance Tips

-

Cleaning Techniques: Warm the nozzle, put cleansing filament, hold down, and draw out to clear away waste. Take a brass brush to cleanse the surface of the nozzle when heated. Additionally, pass cleansing filament between material replacements or following heavy usage.

- Preventing Clogs: Utilize filament through proper maintenance to prevent humidity. Do not print at the wrong temperatures or allow filament to burn in the nozzle by improper heating without printing. Additionally, when a nozzle is completely utilized and expresses clues of a limited clog on the interior, use isopropyl alcohol. Click to learn how to clean 3d printer nozzle.

Best Nozzles for Different Filament Types

|

Filament Type

|

Recommended Nozzle

|

Reason

|

| PLA | 0.4 mm brass | Smooth prints, minimal wear |

| ABS | 0.4 mm or 0.6 mm steel | Handles heat, resists corrosion |

| TPU | 0.6mm stainless steel | Flexible filament needs a smoother internal path |

| Carbon Fiber | 0.6 mm hardened steel or ruby tipped | Abrasive; needs tough material |

| Wood-Fill | 0.6-0.8 mm hardened steel | Reduces clogging, handles particles |

| Metal-Fill / Glow | 0.6 mm tungsten carbide | Strong wear resistance, smooth flow |

FAQ

Can I use any nozzle with my 3D printer?

Does nozzle size affect filament consumption?

How long does a nozzle last?

What's the difference between nozzle diameter and layer height?