Around a million desktop 3D printers under $2,500 were shipped in the fourth quarter of 2023. What started as a fun idea for early adopters and garage tech-tinkerers has transformed the way we create, repair, and build innovative products.

Taking an idea inspired by daily life, getting out the 3D printer, and creating a tangible object in under a few hours offers opportunities to everyone from private individuals to larger enterprises. Whether you want a custom-designed tool for your workshop, a replacement part for your espresso machine, or a prototype for a sales meeting, FDM 3D printing makes it affordable and easy.

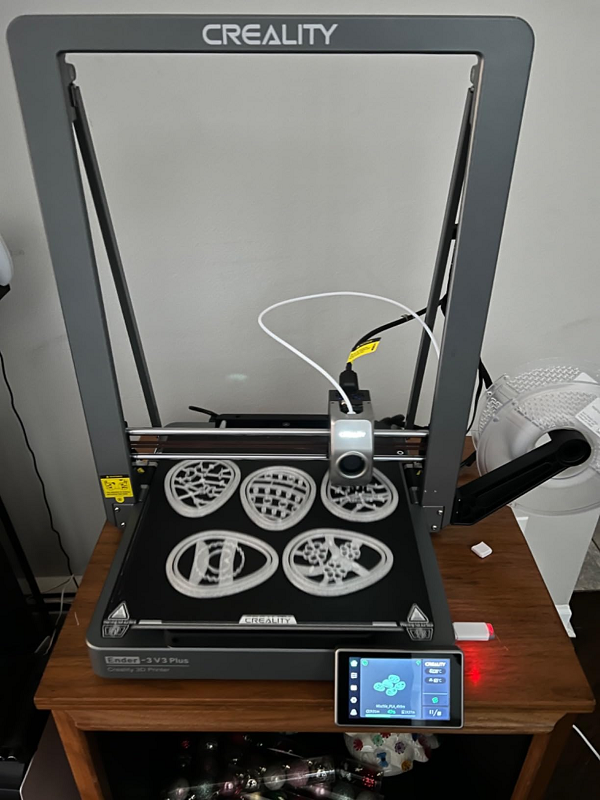

FDM 3D printing technologies mean Fused Deposition Modeling, and they are fueling a cultural revolution. People in manufacturing, small business, science, medicine, and education are learning how FDM 3D printers, like those from industry leader Creality, allow for stunning new advantages – opening doors that would have been blocked before.

What is FDM 3D Printing?

FDM 3D printing uses an additive manufacturing process. Through this process, layers are added on layers using thermoplastic filaments that are heated up to form the designs and pieces users desire. The process follows a basic three-step system:

-

Step 1: Filament extrusion, where thermoplastic filaments (such as PLA, ABS, or PETG) are fed into the 3D printer via a spool.

-

Step 2: Heating and deposition occur, melting the filament inside the printer’s nozzle and precisely depositing it onto a heated build plate.

-

Step 3: The technology behind the printer ads successive layer-by-layer construction, allowing the material to cool and bond as it is created in real-time.

Most of the FDM 3D printers you’ll find on the market have an extruder, print bed, cooling fans, and motion systems working in unison to create the objects you outline in visual software.

The Benefits of FDM 3D Printing

The reason FDM 3D printing is so popular is because of its accessibility. It used to be new technologies that were difficult to access due to the high costs or complex back-end software required to make them work. Now, you can easily purchase such tech and bring it home to teach your kids how to build toys out of their imagination using nothing more than a visual program and some spooled filament.

Besides accessibility, the primary benefits of FDM 3D printing include:

-

Affordability: Unlike some SLA 3D printing or SLS 3D printing, FDM technology is often more cost-effective, making it the best choice for hobbyists, educators, and startup small businesses. Creality printers, like the Ender series 3d printer, offer the accurate results you want, but at a much more affordable price point you need.

-

Versatility: You can use FDM 3D printing materials for practically anything. Need a functional part for your broken toy model? How about prototyping a new invention or cosplay accessory? The ability to choose different filament types and colors adds to the incredible tech flexibility.

-

Ease of Use: FDM printing does not require a lot of software development or engineering background. You can design and print all kinds of pieces with only a few clicks of your screen. Creality’s user-friendly printers ensure access to this groundbreaking technology for users of all skill levels.

Think about FDM 3D printing this way. Imagine you work from home and are constantly frustrated with how your phone sits on your desk. Instead of streaming your favorite show in the background, it lays flat or falls whenever you get a notification on vibrate. Using an FDM 3D printer from Creality means printing a custom 3d printed headphone stand in under an hour and solving your problem. It’s just that easy.

How FDM Compares to Other 3D Printing Technologies

One of the challenges with any new technology is learning what format will work best for your unique needs. When you’re considering FDM technology and 3D printing basics, you should look at how that tech stacks up against other versions.

For example, FDM vs SLA 3D printing is different. SLA uses a liquid resin cured by UV light. While you get some higher-resolution prints, you need a lot of post-processing and expensive filaments.

With FDM vs SLS, you use powdered material and a laser. That is fantastic for industrial applications, but much more expensive than you would want in your residence or for small businesses with limited resources.

Creality printers offer a proven technology that is cost-effective, easy to use, and scalable when you need it most. The material variety opens up design and creative windows that allow you to explore all kinds of printed results while keeping costs low.

Tips for Getting Started with FDM 3D Printing

There is no 100% match for each user. The FDM 3D printing you perform will be based on the needs of your business or hobby. However, following some basic tips should ensure you get a powerful and reliable result time and time again.

Start by choosing the right printer. Entry-level models like the Creality Ender-3 v3 plus are an excellent solution for dipping your toes into the market. When ready, you can upgrade to the CR-series printers for more advanced features.

Next, you’ll want to pick the best filament. PLA is probably the easiest for most users as it is low in price and versatile for different builds. If you’re looking for more durability, you can always grab some ABS or PETG.

You want to be patient with 3D printing of any kind. There will be some troubleshooting involved as you learn the technology. Common issues like poor bed adhesion or stringing can be quickly resolved as you get comfortable with proper bed leveling and temperature adjustments.

When you choose any Creality printer, you can join the various Creality communities. Here you’ll connect with fellow users who offer insight into different 3D printing tutorials and fun projects to improve your skills.

Real-World Applications for FDM 3D Printing

We’ve already mentioned a few examples of how FDM 3D printing can be leveraged in everyday use. The application range is only limited by your imagination.

Bringing home Creality printers allows you to design everything from functional engineering parts to artistic creations. You can see 3D printed parts in everything around you, like:

-

Schools teaching STEM concepts to kids using FDM printers for reusable pencils and backpack accessories.

-

Entrepreneurs creating new businesses rapidly develop prototypes that attract angel investors.

-

Cosplay parts for intricate helmets, armor, and accessories before attending popular conventions like Dragon or Comic-Con.

-

Home and DIY projects where you need some custom organizers or tools to get that IKEA bookshelf perfectly aligned with your wall closet.

There have even been examples of Creality users building a fully functional RC car chassis as well as custom holders for video game systems and emulator accessories popular on social media.

Bringing ideas in your head to the physical world has never been easier. Custom FDM 3D printing is not just the wave of the future, it is a key to unlocking the creativity of tomorrow’s makers.

Unleash Your Creativity with FDM 3D Printing

Being able to take advantage of all that FDM 3D printing has to offer has never been easier. 3D printers are no longer in the “early adopters” product phase. They are now affordable, easy to use, and versatile – ensuring everyone from kindergarten teachers to backyard startups has access.

Whether you’re getting started with the new technology or looking to expand your printing business, Creality is here to help. With affordable, professional-grade machines that offer all the flexibility and customization you could want, you can pick up a printer today and start your next project in only a few minutes.

FDM 3D printing is a wonderful way to breathe life into your imagination. Start your journey now and select your preferred Creality model.