What if you could create objects so detailed and smooth that you would think it was by magic? At least, it feels that way when you hold it in your hand. But it’s not magic. It’s a new way for businesses and creators to bring their most complex designs to life. Introducing the innovation of DLP 3D printing.

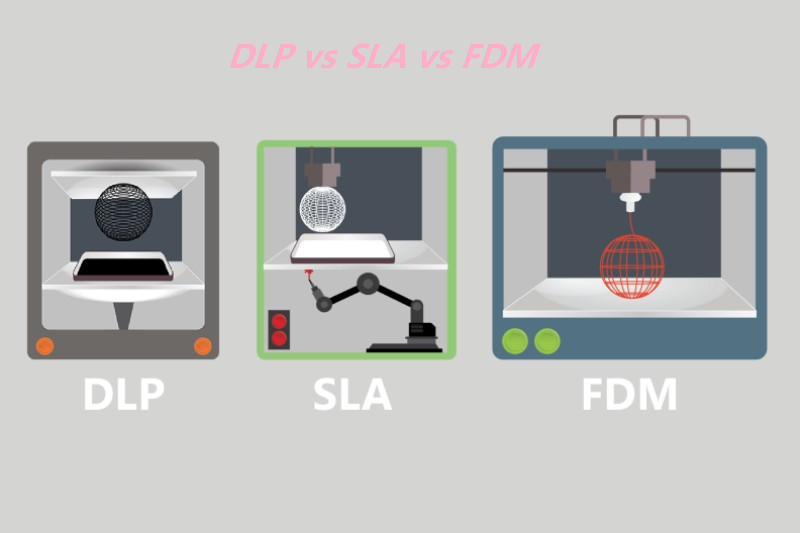

3D printers basically have the same functions, but they don’t all use the same processes. DLP 3D printing, for example, cures and hardens liquid resin using light. Because it cures resin layers simultaneously using projected light, it is significantly faster and more precise than traditional methods that melt and extrude plastics.

If you want to create pieces that are 10x better and faster than traditional printers, this may be exactly what you're looking for.

What is DLP 3D Printing?

The future of manufacturing is DLP or Digital Light Processing. It is a newer, updated version of traditional 3D printing. Instead of slowly building objects by melting plastic thread by thread, this technology uses powerful light to turn liquid Photopolymer resin into solid objects instantly.

Here is a practical example of this: Old-school 3D printers take 30 minutes up to 12 hours to make something, but DLP printers can complete the same project in a fraction of that time. Reducing processing time means you can create twice as much in half the time.

Compared to Stereolithography - SLA uses a tiny laser that slowly draws layer by layer, which slows it down. Our approach is distinct in that it uses a bright light that fills the entire layer, significantly improving printing efficiency.

Compared to Fused Deposition Modeling - FDM printing works similar to a hot glue gun; it squeezes out melted plastic that leaves visible lines between layers. Our printing method creates objects with clean, sharp edges that look professionally made.

Material Differences – FDM printers use solid plastic strings, while DLP and SLA both start as liquid that turns solid. What makes the difference is that we can harden entire layers in just a split second, which means improved productivity and less waste.

This print method is perfect for jobs with intricate details that require perfect accuracy and quick finishing times. Dentists and orthodontists who need to create complex objects quickly, like custom dental tools or prosthetics, will find this especially useful. It’s also great for intricate jewelry designs or product prototypes.

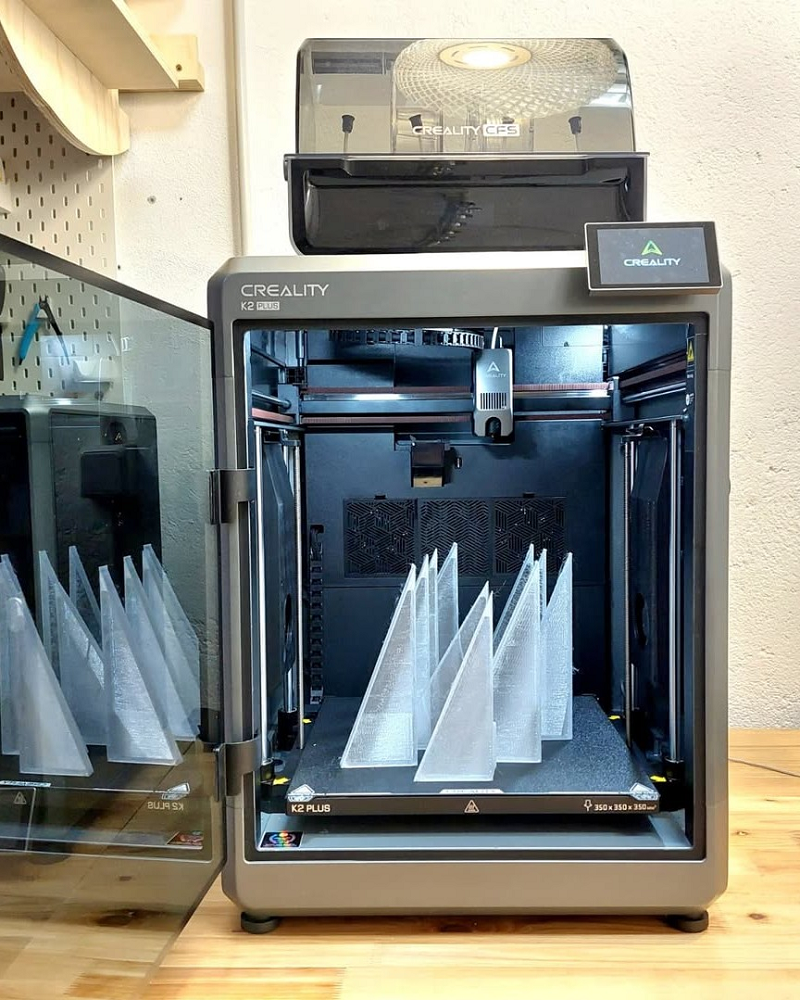

However, if you need a versatile, cost-effective and reliable FDM 3D printer, K2 Plus 3D printer is the perfect choice. With high print quality and support for a wide range of filament types, it's ideal for professionals and hobbyists alike. Buy the K2 Plus today and bring your 3D printing ideas to life!

How Does DLP 3D Printing Work?

DLP 3D printing is an additive manufacturing technique that uses light to cure liquid resin into solid objects. But what makes it so fast and precise? Let’s break it down step by step.

Step 1: Preparing the 3D Model

Before printing begins, a 3D model is sliced into thin layers with the help of Computer-Aided Drafting (CAD) software. Each layer represents a cross-section of the final object. The software also determines support structures, if needed, which help stabilize overhanging parts during printing.

Step 2: Projecting Light Onto the Resin Vat

The DLP projector displays an image of the first layer on the liquid resin’s surface. The UV light exposure instantly cures the exposed areas of liquid resin, hardening the first layer.

Step 3: Layering and Building the Object

As each layer cures, the build plate lifts slightly, allowing fresh liquid resin to flow underneath. The projector then flashes the next layer, repeating the process until the object is complete. The precise layering of the printer’s Z-axis movement prevents distortion.

Step 4: Post-Processing

After the procedure is finished, the extra resin is removed from the object by rinsing it in isopropyl alcohol (IPA) or another cleaning solution. A final UV curing completes the last step, strengthening the material and guaranteeing complete polymerization.

Advantages of DLP 3D Printing

What makes DLP 3D printing such an excellent choice for all types of professional applications is its processing speed. Curing entire layers all at once results in greater detail and smoother surfaces. It reduces print times and enables batch production for industry prototyping.

Thanks to the innovative light projection technique, sharp details and high surface quality reduce the necessity of extensive post-processing. This makes it ideal for applications needing precision for small details.

DLP printers also have a significant benefit in terms of material choices, which lets customers employ different resins depending on specific needs. Standard resins are suitable for general prototypes, ensuring the durability of working parts. Castable resins are widely used in jewelry and dental applications, while flexible resins are ideal for rubber-like components. Engineering resins are strong and heat resistant, making them suitable for harsh conditions.

When compared to FDM printing, DLP printing uses materials more efficiently and produces less waste. Its versatility allows it to be used for both one-time printing and bulk manufacturing while maintaining the same excellent quality throughout multiple prints. This improved methodology makes it ideal for both prototype and final manufacturing.

Applications of This Technology

These are just a few of the applications that will benefit from this type of printer. We also suggest a few models for each purpose, allowing you to customize your choice.

Dental & Medical: Custom Precision

A Creality printer such as the HALOT-ONE would be an excellent choice here. Applications include dental aligners, crowns, bridges, orthodontic models, hearing aids, custom prosthetics, implants, and anatomical models for surgical planning. Same-day dental restorations reduce patient wait times.

Jewelry: Fine Detail for Casting

This printer produces sharp, intricate designs for gold, silver, and platinum casting. It’s faster and more cost effective than traditional wax carving. This makes it perfect for bespoke and small-batch jewelry production. The Creality HALOT-SKY is a great, high-resolution 3D printer and a solid option.

Engineering & Prototyping: Rapid Testing

The advanced technology allows the user to create functional prototypes with strong mechanical properties. You can also make custom molds for small-batch manufacturing. Businesses can optimize designs faster, thanks to rapid iterations. The Creality HALOT-LITE, a versatile resin 3D printing option, supports various engineering materials.

Art & Education: Expanding Creativity

Teachers and educators can create miniatures, sculptures, and educational models for study. The result is highly detailed pieces that traditional sculpting can’t match. Colleges and universities use DLP for hands-on STEM learning.

Selecting the Best Printer for Your Needs

When shopping for a high-resolution 3D printer, focus on these four main factors:

Resolution: This affects the print’s clarity and smoothness. A higher resolution means more detail and smoother surfaces with no bumps or rough edges.

Build volume: This is the maximum object size you can create. Larger build volumes let you print more oversized items or multiple smaller ones in a single session.

Material Compatibility - If your industry uses different materials, make sure the model you choose supports multiple variations. For instance, some applications require castable resin, while others may need flexible resin.

Software and connection options - easy-to-use software with features like Wi-Fi and USB connections will save you time and frustration, making it more convenient to send designs to your printer from different devices. Consider these factors when choosing the right printer for your specific needs.

Why Choose Creality?

-

Affordable, dependable, high-resolution printing.

-

Improved light projection for consistent, excellent prints.

-

Easy-to-use software that is simple to install and use.

A dental lab using Creality’s printer reduced production time by 50%, improving efficiency and customer satisfaction.

The Future of This Technology

DLP 3D printing has a very bright future ahead of it. Scientists are developing faster-curing resins to shorten production times while also making more substantial materials that can endure heat better than current possibilities. New dual-material capabilities allow you to print using two resins in a single build, and interesting hybrid technologies combine this printing approach with CNC machining for superior finishing.

Plus, this tech is expanding beyond just little tasks. Manufacturers are creating larger printers with more excellent build surfaces for industrial applications, automating production lines to produce many things at once, and using AI to improve printing efficiency and accuracy.

FAQ Section

Q: How costly is DLP resin?

A: DLP resin prices vary by kind and brand. Standard resins begin at $30 per liter, However, specialist resins, such as castable or biocompatible resins, can cost more than $100 per liter.

Q: Can DLP printers handle larger objects?

A: Most DLP printers are intended for small to medium-sized prints. However, newer models with higher build capacities are increasing the capacity to print larger items.

Q: What if I need more help deciding on a Creality DLP Printer?

A: That’s no problem. We have buying guides that go a little more in-depth to help you in making your final decision.

Final Thoughts

DLP 3D printing is an effective tool for both professionals and enterprises, providing speed, precision, and efficiency. This technology improves productivity and lowers costs in areas such as engineering, dental, medical, and academic environments.

Choosing the correct printer is extremely important. Investing in a high-quality printer leads to better outcomes, shorter turnaround times, and a more efficient workflow.

Ready to experience ultra-detailed 3D printing?