Originally a mechanical engineer at a state-owned enterprise, Song Hu frequently needed physical prototypes to validate designs. Traditional model-making methods were slow and expensive, often delaying product iterations. Seeking greater efficiency, he introduced 3D printing into his workflow. The result? Faster validation and more flexible design cycles. Realizing its commercial potential, Song founded UC3D, shifting from machine reselling to running a professional 3D printing farm based in Yichang—a third-tier city in central China.

Usage Scenarios and Pain Points

UC3D serves a wide range of clients—including product developers, e-commerce sellers, and B2B customers—offering services such as rapid prototyping, small-batch customization, and modular model production. A standout demand comes from large-format prints sized between 260–300mm, which are common in architecture models, IP figurines, and industrial components. Most farms, however, operate with printers limited to 220–250mm, making it hard for them to accept such orders.

Moreover, clients today demand more than just printing—they expect speed, accuracy, aesthetic quality, and stable output at scale, all while keeping costs competitive.

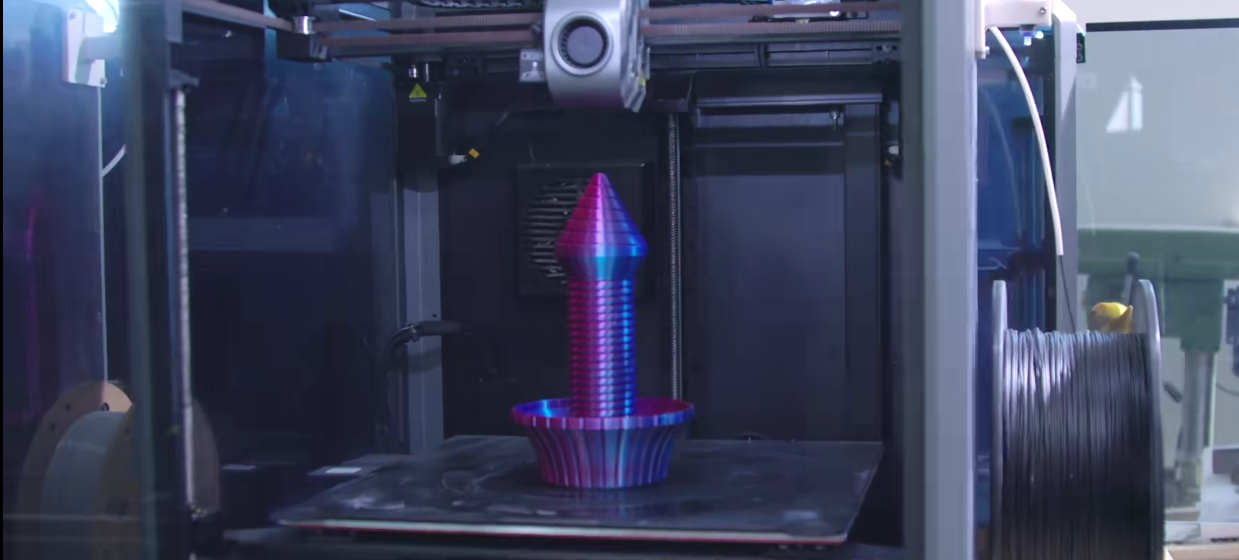

Below are examples of large-format toy components and a custom lightsaber printed by UC3D. These pieces showcase the farm’s ability to produce high-quality, visually striking models at scale—helping clients bring imagination into physical form.

Product Solution

“Print quality and precision matter a lot to me. With Creality, I trust the brand and their pre- and after-sales support—it gives me peace of mind.”

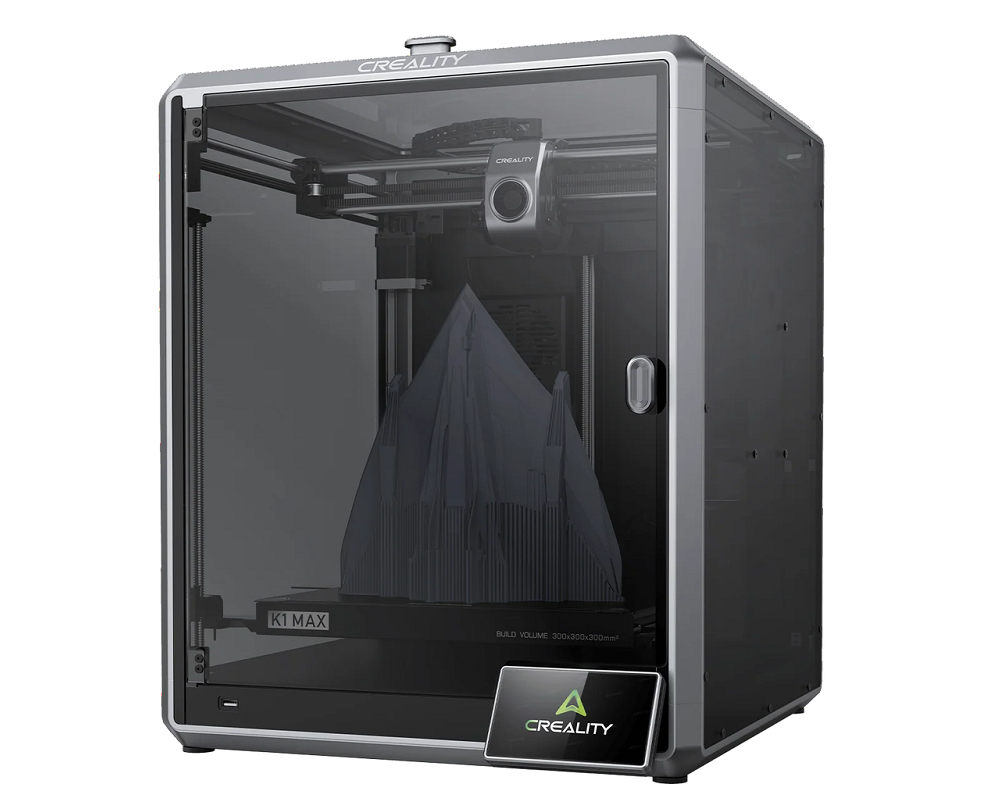

To meet these challenges, Song equipped his farm with 25 Creality K1 MAX printers. To address these needs, UC3D invested in 25 units of the Creality K1 MAX, making it the core of their farm operations. The K1 MAX delivers a blazing-fast speed of 600mm/s, with a large 300×300×300mm build volume, making it ideal for both large models and bulk production. This gives UC3D a major competitive edge—handling orders that most other farms simply can’t take.

Building on the strengths of the K1 MAX, UC3D has developed a versatile range of material combinations and print applications—capable of handling everything from creative models to engineering-grade parts. Below is a snapshot of their most common configurations.

K1 MAX Print Configuration Recommendations

USE PLA/PLA+/Wood-filled PLA

- Filament Type: PLA / PLA+ / Wood-filled PLA

- Print Application: Figurines, cultural toys, display pieces

- Print Quality: Smooth surface, good detail, ideal for batches

USE ABS/PETG/TPU

- Filament Type: ABS / PETG / TPU

- Print Application: Tooling parts, mechanical components

- Print Quality: Strong bonding, structurally sound

USE Color PLA / Mixed Materials

- Filament Type: Color PLA / Mixed materials

- Print Application: Segmented large models, architectural parts

- Print Quality: High fit accuracy, strong visual impact

Results and Value Presentation

With 25 K1 MAX units running in parallel, UC3D produces 12.5–25kg of prints per day, maintaining a >90% success rate. This low scrap rate keeps operational costs low and ensures strong margins even on large-volume jobs.

To optimize efficiency, the team has implemented a semi-automated workflow—including slicing presets, remote monitoring, and grouped job queues—to streamline production.

Orders are primarily received through major e-commerce platforms such as AliExpress, Etsy, and local marketplaces, depending on the region. By analyzing customer traffic and search trends, UC3D forecasts demand and dynamically adjusts capacity.

On average, printing a mid-sized figurine (~300g) costs less than $3 in materials and electricity. The finished product typically retails for $14–28, depending on complexity and design value.

This model has helped UC3D achieve annual revenues exceeding $500,000, making it a benchmark example of a profitable and scalable 3D printing farm in its region.

Conclusion

In the age of digital customization, UC3D has proven that speed, size, and smart management are a winning combination. With Creality’s K1 MAX as its backbone, the farm has not only expanded its service range but also built a profitable, scalable business that leads its market segment.