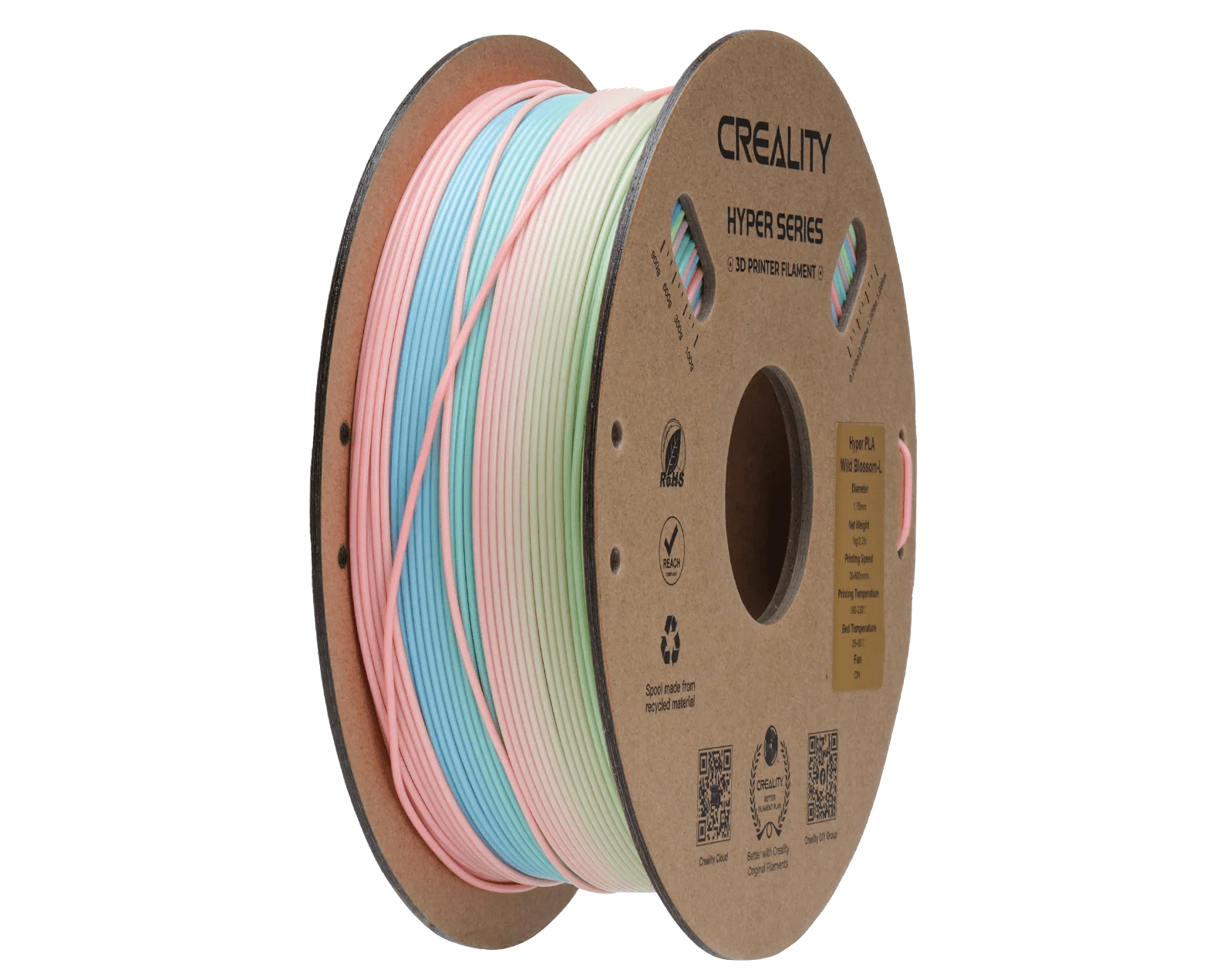

Polylactic Acid (PLA) is one of the most common 3D printing filaments because it is affordable, easy, and eco-friendly. In order to achieve clean and smooth 3D prints, it's necessary to maximize parameters like PLA print temperature, bed temperature, and cooling.

This guide features optimum PLA print temperature, bed level, and more that will prevent you from having issues like warping or stringing — and achieve professional-grade results every time.

Recommended PLA Print Temperatures at a Glance

Here’s a quick overview of the typical temperature settings for PLA:

|

Component

|

What It Is

|

Typical Temp for PLA

|

Purpose

|

|

Nozzle

|

The metal tip where melted PLA is extruded onto the build plate

|

190°C–210°C

|

To control extrusion flow and print detail

|

|

Heatbed (Heated Bed)

|

The heating element beneath the build plate

|

50°C–70°C

|

To prevent warping; improves first-layer adhesion

|

|

Build Plate

|

The surface on which the print is built

|

Heated via the heatbed

|

Surface for the print to stick to (glass, PEI, etc.)

|

|

Melting Temperature

|

The temp at which PLA becomes fully molten

|

150°C–160°C

|

To indicate PLA’s phase change to liquid

|

|

Glass Transition Temperature

|

Temp at which PLA softens (but doesn't melt)

|

60°C–65°C

|

Important for heat resistance & stability after printing

|

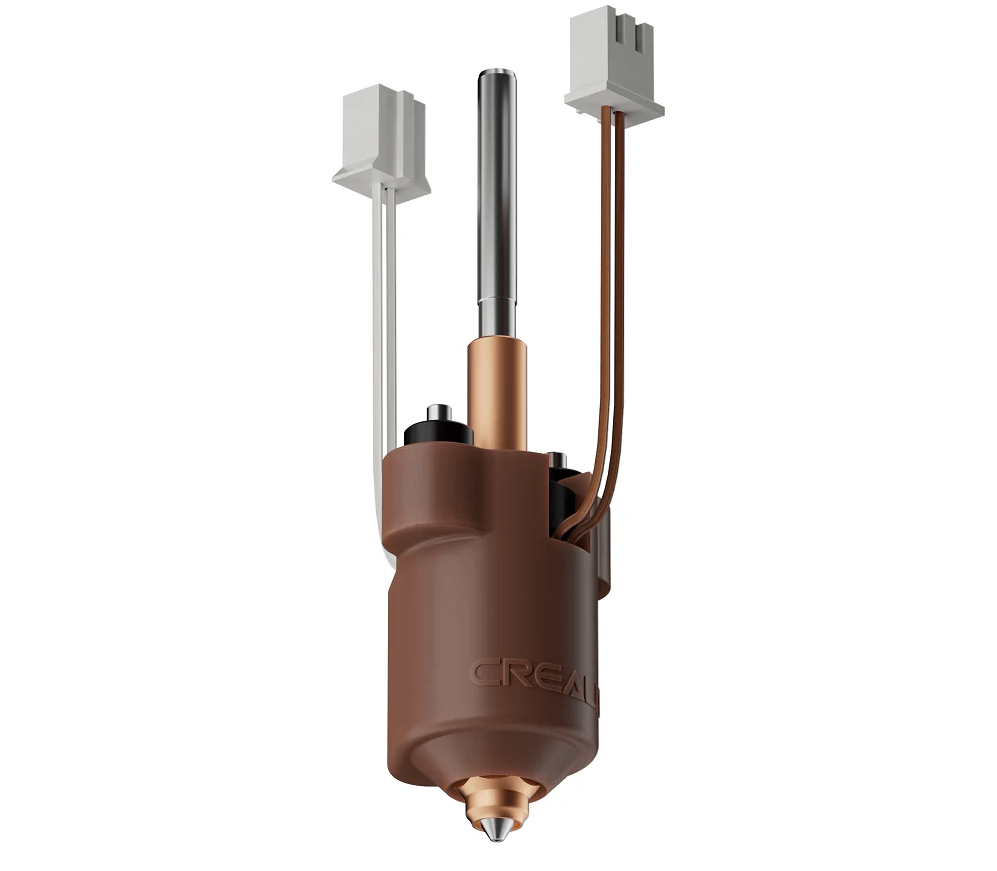

Nozzle Temp for PLA

The PLA nozzle temperature, which in many cases is the same as the extruder temperature, usually ranges around the same 190°C–220°C range, and it's essential for enabling the filament to melt correctly and extrude smoothly through the extruder. Scientific investigation indicates a range between 190°C and 220°C is best for most PLA filaments:

Lower temperatures (190°C–200°C): These reduce stringing and oozing, improve surface finish, especially for delicate prints or overhangs. They may, however, result in worse layer adhesion if too low.

High temperatures (210°C–220°C): They enhance layer adhesion and print strength, ideal for functional parts but might produce stringing or blobs if too high.

For example, some give a print temperature for PLA of 215°C ± 10°C, while others give 180°C–220°C, depending on color and nozzle size. The way to find the optimal PLA nozzle temperature is to print a temperature tower, which attempts a set of temperatures in a single print to identify the best setting for your filament and printer.

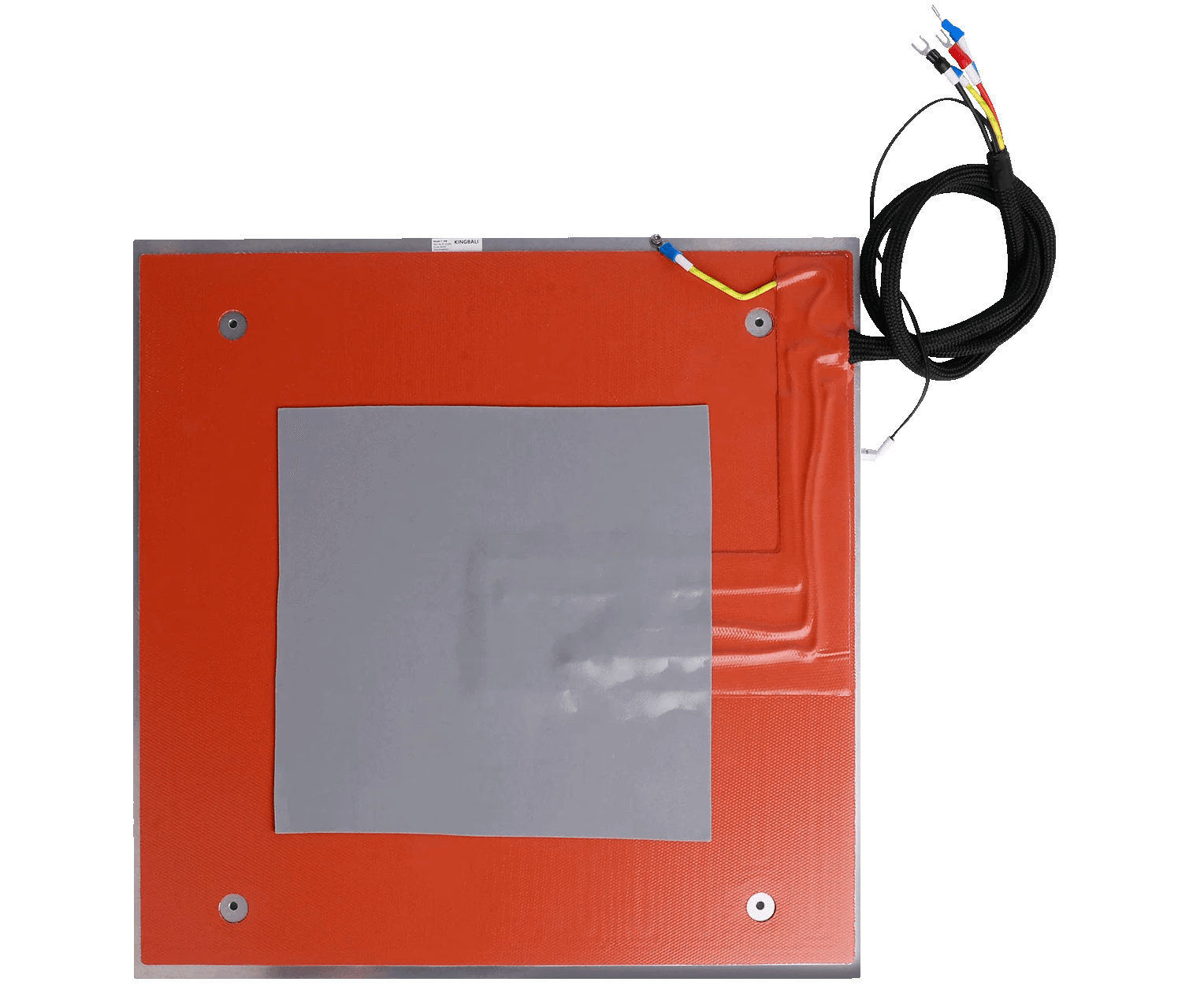

Bed Temp for PLA

The best bed temp for PLA or PLA build plate temperature enhances the first-layer adhesion and reduces warping, particularly for large prints. The range of 50°C to 60°C is most often suggested:

50°C–60°C: This is suitable for enjoying good adherence to the build plate, particularly on glass or PEI. One of the most popular slicers, Cura, has a default setting of 60°C for PLA.

No heated bed: PLA can print without a heated bed, especially for small prints, with adhesives like glue stick, hairspray, or blue painter's tape on glass.

A PLA bed temperature of 50°C–60°C is usually recommended to minimize warping and improve print stability. Some forum users at sites like Reddit, though, report success with 45°C–50°C on PEI plates for specific printers.

Thermal Properties of PLA: Glass Transition & Melting Temperatures

To fine-tune your PLA print settings, it’s helpful to understand how the material behaves under heat. Two of the thermal properties of PLA — the glass transition temperature and melting point — determine how PLA relaxes, melts, and solidifies when printed.

PLA Glass Transition Temperature

The glass transition temperature of PLA is between 60°C and 65°C, where the material starts to soften from a hard, crystalline state to a soft, rubbery one. PLA prints will start to structurally fail at this temperature and thus are not appropriate for heat applications, such as on a car in the hot sun.

Knowledge of this attribute is critical where thermal stability is a concern. Annealing, the process of heating PLA prints up to about 90°C and slow cooling, can enhance heat resistance.

Melting Temperature of PLA

PLA melts between 150°C to 180°C, although a commonly cited figure is 175°C. This is where PLA fully melts from solid to liquid state, apart from the printing temperature that has a slightly higher value to allow for easy extrusion.

Wikipedia and 3D Insider concur with this range, noting that the additives or dyes present in the filament would raise the melting point slightly. For utilitarian 3D printing, the PLA print temperature typically is modified to a higher setting (190°C–220°C) in order to counteract filament formulation and printer dynamics.

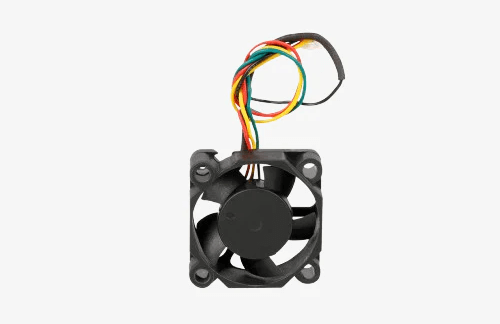

Coolling Fan Settings for PLA

Proper cooling is needed during printing with PLA as it affects print quality, surface finish, and overhang and bridge success significantly.

First 1-2 layer: Disable the cooling fan for the first 1-2 layers. This allows the filament to stick properly to the bed and not cool too early.

Remaining layers: Enable the fan at 100% in order to solidify the layers quickly in order to enhance strength and detail.

Tips for Optimizing PLA Print Settings

To achieve the best results with PLA, consider the following tips:

- Follow manufacturer’s recommendations: Start with the provided temperature settings from the manufacturer for the filament.

- Print a temperature tower: Print a temperature tower to try printing and testing nozzle temperatures at 5°C–10°C intervals in order to find the best temperature for your material, minimizing stringing and maximal strength.

- Level and clean the bed: Level the build plate and desiccate dust or oils on it, clean with soapy water for optimal adhesion.

- Use adhesives if needed: For non-heated beds or difficult prints, apply glue stick, hairspray, or blue painter's tape to enhance adhesion.

- Adjust print speed and cooling: Utilize print speeds of 40–60 mm/s for standard printers, as advised by FormFutura, and have the cooling fan enabled to prevent overheating and improve bridging.

- Monitor environmental factors: Avoid drafts and a consistent ambient temperature (around 22°C–30°C) from warping, especially in enclosures.

FAQs about PLA Print Temperature

Q: Why is my PLA stringing even at low temps?

A: If your PLA is stringing even at lower temperatures, it's probably because of reasons other than heat alone. Stringing occurs when long, thin strands of plastic are extruded when the nozzle is moving, and although lower temperatures will normally cure it, other things may be the culprit:

-

Inspect your retraction settings; they may require tweaking to retract the filament adequately on moves.

-

Make sure your filament is not old or wet, as this will cause oozing.

-

Clear out the nozzle to eliminate clogs, which can result in uneven extrusion.

Q: What if my PLA won’t stick to the bed?

A: If your PLA will not adhere, it may ruin your print. These are a few things you can try:

-

Make sure your bed is level and flat, because a crooked bed will prevent sticking.

-

Make sure your bed temperature is at 50-60°C and the first layer nozzle temperature is at about 205-210°C for better sticking.

-

Attempt to use adhesives like glue sticks or hairspray if needed, especially if you do not have a heated bed.

-

Clean the build plate using soapy water to remove any residue.

-

Calibrate the Z-offset so the nozzle is at the correct height for the first layer.

Summary

Having your PLA print temperature settings right can be the difference between a defective print or one that is flawless. According to guidelines, 190–220°C is suitable for nozzle temperature, and 50–60°C for the bed temperature, but every printer and filament brand can respond just ever so slightly differently.

So do not hesitate to experiment with something like temperature towers, and always take advice from your filament supplier.