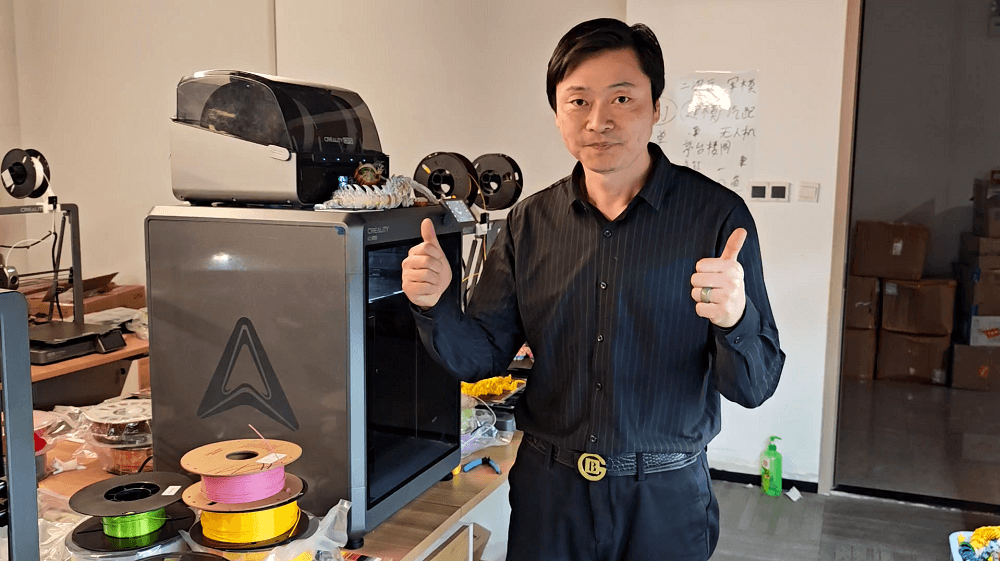

At the heart of Qingdao’s thriving tech-manufacturing ecosystem stands ZC3D Printing Farm, founded by visionary entrepreneur Qin Siyun. Covering over 600 square meters and equipped with 525 Creality 3D printers—including 350 Ender-3 V3 PLUS and 150 K1 SE units—ZC3D has become a beacon of scalable, efficient production in China. With a team of 35 skilled operators and engineers, the farm delivers agile, high-throughput services for a broad range of clients, from university-industry research collaborations to global trade partners and enterprise-level custom manufacturers.

Usage Scenarios and Pain Points

ZC3D sits at the intersection of creativity and capacity, enabling clients to move from concept to product at unprecedented speed. The farm helps academic institutions rapidly prototype educational tools and experimental components. For overseas markets, ZC3D handles high-volume production of toys and anime figures with impressive efficiency and precision. Corporate clients count on the farm for short-run, highly customized lifestyle products and cultural collectibles, while distributors benefit from stable, on-demand manufacturing that keeps pace with constantly evolving market trends.

But running such a diversified operation presents unique challenges. ZC3D regularly handles large-scale orders requiring thousands of units within days, especially during peak export seasons. Frequent product design changes—common in the anime and gift industries—require the farm to stay highly responsive.

Cost control is equally critical. Many of ZC3D’s clients operate with slim profit margins, so every gram of filament and every minute of print time counts. Managing over 500 machines within a limited area also creates logistical pressure. To tackle this, the farm has implemented a semi-automated task assignment system that uses QR-coded build plates, centralized monitoring software, and batch management protocols. Each printer is tracked through a digital dashboard, allowing real-time control and error response. Daily operations are divided into shift-based zones, enabling lean, synchronized management across hundreds of machines.

ZC3D’s capability goes far beyond machine count or workflow—it comes to life through the quality of its printed products.

The examples below showcase real client commissions. The dragon gemstone egg and dragon sculpture were produced for an international distributor focused on fantasy-themed collectibles. These intricate models feature layered surface textures, multi-color effects, and even articulated joints, highlighting ZC3D’s ability to manufacture visually captivating and structurally complex designs at production scale. Meanwhile, ZC3D also fulfills private commissions for anime figurines and cultural creative products, delivering crisp detail and high fidelity to bring original designs to life.

Alongside that, ZC3D regularly fulfills private custom orders for anime figurines with rich surface detail and precise dimensional fidelity, helping creators bring their characters to life.

Product Solution

Scaling Smart: Choosing the Right Tools for the Job

To meet its scaling ambitions and high-efficiency targets, ZC3D turned to Creality for a dependable, future-proof solution. Among the options, the Ender-3 V3 PLUS stood out as the ideal workhorse—delivering the perfect combination of reliability, affordability, and consistent performance. With 350 Ender-3 V3 PLUS printers operating in continuous cycles, it remains the backbone of ZC3D’s high-output manufacturing system.

For projects that demand even greater speed and detail, such as highly customized parts or intricately designed models, ZC3D relies on a fleet of 150 K1 SE printers, known for their rapid print speeds and high-resolution output. Additional Creality machines are used for R&D, prototyping, and fast design iteration, giving the team the agility it needs to stay ahead of the curve.

Ender-3 V3 Plus

K1 SE 3D Printer

Ender-3 V3 PLUS

- Filament Type: PLA / PLA+ / Wood-filled PLA.

- Printed Items: Anime figures, cultural & creative toys, classic architectural models.

- Print Quality: Smooth surface, good detail performance, ideal for medium-precision mass production.

K1 SE

- Filament Type: PLA / ABS / PETG / TPU

- Printed Items: High-speed custom figures, complex household items, small-batch gift orders.

- Print Quality: Fast printing, fine layer lines, supports more structurally optimized designs.

Results and Value Presentation