What if you could bring the sensation of Formula 1 racing into your own home. both as a stunning standing model and as charismatic, finely detailed components that embody the spirit of speed and competition? In Formula 1 motor racing, where every thrill captivates bystanders and every microsecond counts, the secret to performance lies in both the driver’s expertise and the mechanical sophistication of the car. This realm of precision and innovation has found a powerful ally in 3D printing.

The advantage of formula 1 3D printing in its ability to give teams a competitive edge by enabling them to quickly prototype and produce parts. This technology leads to significant performance gains during races, allowing teams to adapt and innovate on the fly. As F1 teams gradually embrace this groundbreaking technology, collaborations between 3D printing pioneers and racing teams have begun to flourish, driving advancements in the sport.

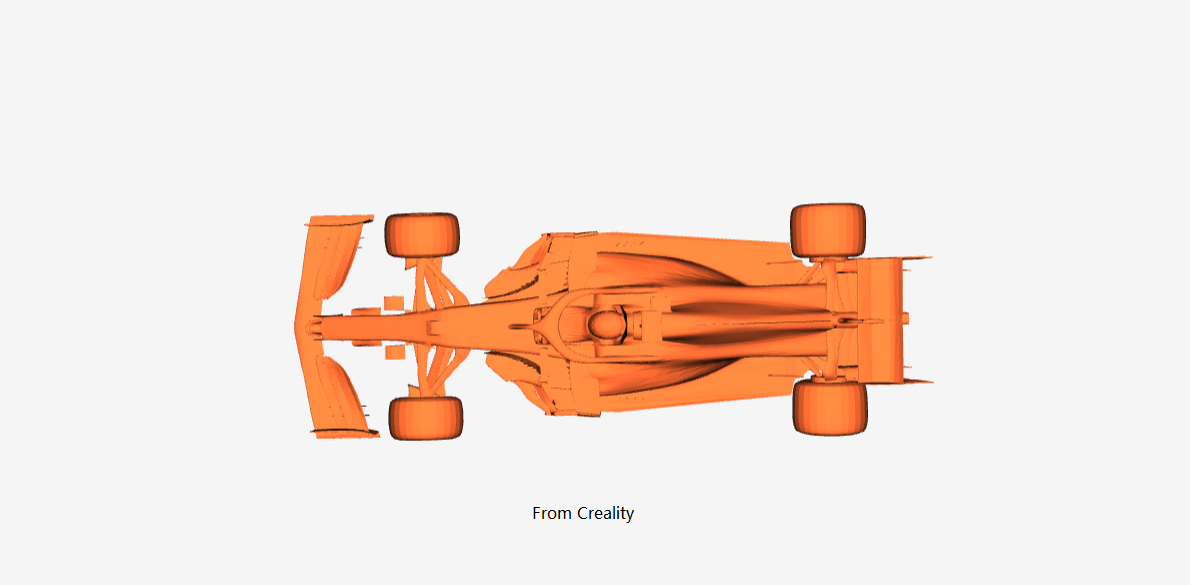

Now, with cutting-edge 3D printers—like the innovative units from Creality—you can turn the dream of designing comprehensive 3D printed F1 cars into reality. These creations symbolize the accuracy and spirit of the racing world, allowing enthusiasts to experience a piece of the action firsthand. So, buckle up and dive into this guide to learn how 3D printing is revolutionizing Formula 1.

Why 3D Print F1 Cars?

The appeal of 3D printed F1 car replicas depends on their power to present personalization and extraordinary particulars that trap the core of the real vehicles. 3D printing F1 cars permit fans and sculptors to modify outlines to their mechanical requirements or personal tastes.

Of course, this is impractical with off-the-rack models. Besides, the customization options are infinite, from regulating the scale to adding special decals. Now, it’s feasible to produce parts with intricate inner frames like honeycomb or lattice structures, which are not possible with classic techniques.

As regards utilization, 3D printing catches the eye due to its competence in quick prototyping, which is specifically valuable for Formula 1 racing teams. This is because with this technology you can design, produce, and test new components. The advantages of 3D printing in Formula 1 include weight reduction, design flexibility, and rapid prototyping capabilities that enhance performance and efficiency in the demanding environment of motor racing.

Also, 3D F1 cars act as excellent educational devices. They offer enthusiasts and students a firsthand knowledge of engineering, physics, and aerodynamics. Constructing these units from scratch improves environmental awareness and technical expertise.

So, they’re ideal assignments for STEM education. Additionally, for laypeople, replicas are not only related to making models; they’re about reviving the excitement of Formula 1.

Every 3d f1 car model could be a task that expresses both an admiration for the sport and an acknowledgment of the innovative technologies that translate advanced building and advanced racing.

"3D printing is not just a tool; it's a revolution in how we create and innovate” – said Avi Reichental, Former CEO of 3D Systems.

How to Design Your F1 Car Model?

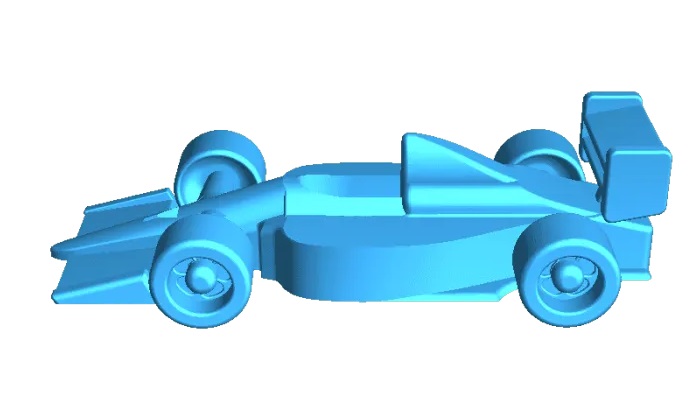

Crafting a 3d F1 car model empowers for thorough artistic command over each specification of the model, beginning with the twists of the body to the details of the aerodynamics. Below is a brief advice on getting going.

Research and Collect References: Start by gathering elaborate images and outlines of the F1 car you desire to replicate. Be careful of the rare attributes and percentages that describe the design of the ar.

Select the Design Software: The next important step is to choose a 3D modeling software that fits your expertise level and needs. You can either craft the 3D printed F1 car model utilizing CAD software or install a finest model from internet sites that give 3D printing field. Famous alternatives for accuracy modeling involve Autodesk Fusion 360, Blender, and SolidWorks for more intricate and complete layouts.

Begin Carving: Begin modeling the main shape of the car applying your references, first concentrating on the body. Then proceeds to more definite components such as wheels, wings, and cockpit. Also, make sure that every part is balanced and properly shows the actual car.

Improve and Detail: Include key factors that will refine the realism of the model. This involves textures such as specific decals, carbon fiber ornaments, and particular elements for instance the cockpit device.

Modify Model for 3D printing: When you possess the model, make changes appropriate for printing. For example, inserting assistance for danging components such as mirrors and rear wings. Besides, examining the wall thickness of the model is enough to avoid cracking post-printing.

Scale and Complexity Considerations: Review the capacities of the 3D printer. For complex outlines that need great detail, confirm the printer can tackle little nozzles and thin coatings.

How to Choose the Right 3D Printer for F1 Models?

The key to the successful and fine 3D printing F1 is to select the correct 3D printer. Here’s what to keep in view:

Printer Features Contrast

Ender-3 V3 3D Printer - Best 3D Printer For Beginners

This Creality 3D printer is perfectly suitable for hobbyists and newbies who want Formula 1 3d printing. The printer promotes a CoreXZ system for paces to 600mm/s, a secure mental frame with die-cast elements.

Also, Ender-3 comes with a straightforward extruder that tackles a range of filaments. Besides, its bifold cooling fans and fast-swap tri-metal nozzle help elaborate and intricate model printing. All these features of Ender-3 V-3 make it one of the best buy printers on sale.

Creality K2 Plus - Next-Level Professional 3D Printer

Creality K2 Plus a best rated 3D printer is ideal for innovative consumers. This is because the printer provides a big build volume of 350x350x350mm along with a smart filament set-up that assists up to 16 colors.

Consequently, it improves the lovely details of a 3D printed F1 car. Besides, the step-servo motor arrangement offers great acceleration, crucial for quick and comprehensive printing. Additionally, its double AI camera allows it to regulate flow speed and warn about failures.

Key Features to Consider

Speed and Resolution

Great resolution and flexible pace settings are important for attracting the complicated particulars of the 3d F1 car model. The two of the printers provide adaptable settings to regulate detail and printing speed effectively.

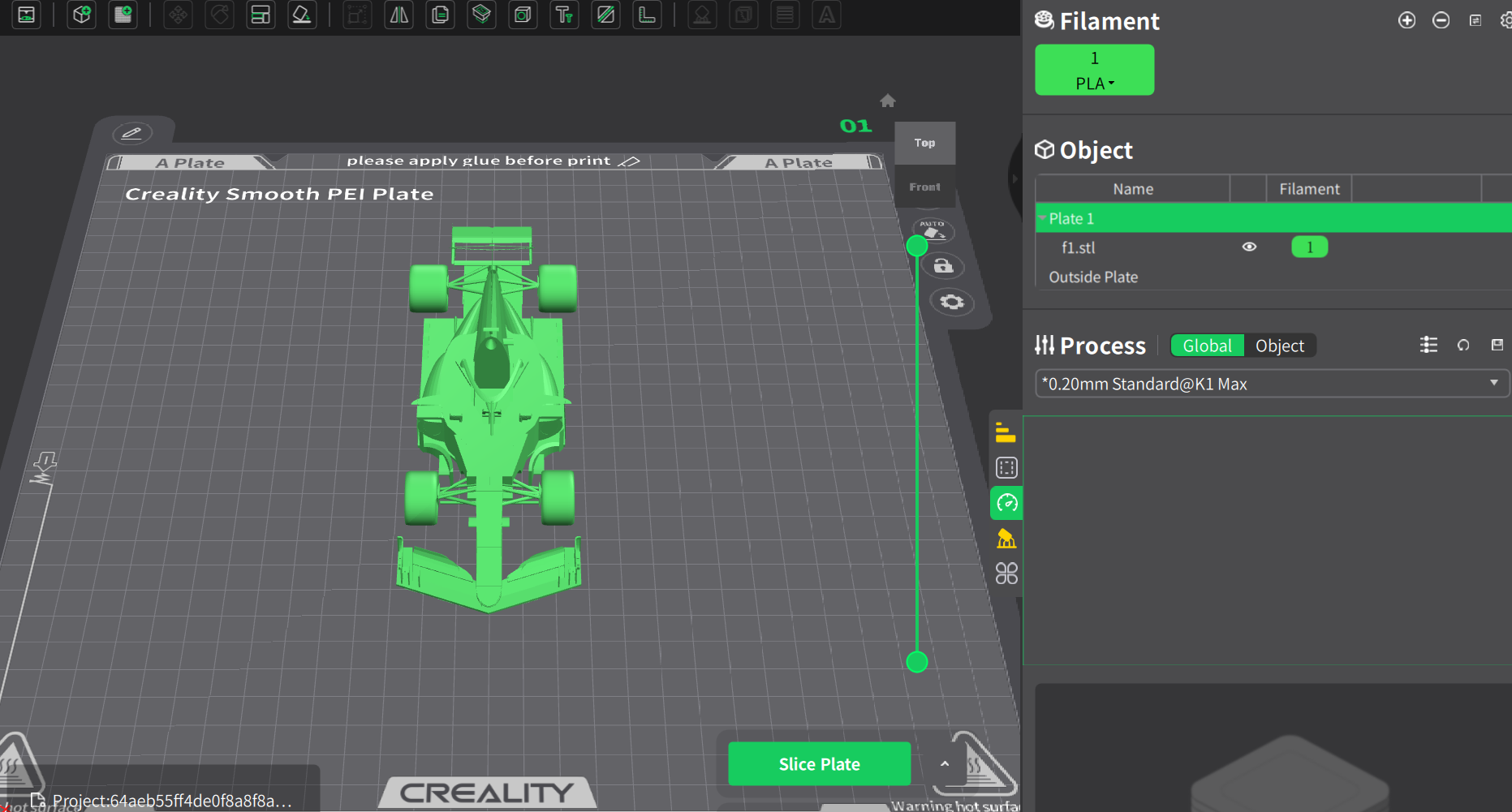

Preparing to Print Your F1 Car

Arranging Your Printer

To start printing the F1 car prototype, it’s vital to arrange your 3D printer properly. For this first, verify the print bed is excellently balanced. Use the auto-adjusting attributes of the printer to regulate other settings, for instance, Z-axis height and the extruder arrangement.

Besides, fix the right temperatures for the two heated beds and the extruder depending on the filament kind. Also, charge the filament properly, confirming it serves effortlessly within the extruder without any obstacles.

A balanced and continuous filament circulation is necessary for through and complex prints such as F1 cars.

Choosing the Correct Materials

Selecting the right filament is the secret behind the triumph of the 3D printed F1 car. Mediums such as PLA are endorsed for newbies because of their user-friendliness and quality detail accuracy.

In the case of modern uses, materials like PETG or ABS provide enhanced longevity and elegant touch resolution, good for the complex parts of F1 cars. Every matter needs particular temperature ranges, that a printer must back effectively.

Chuck Hull - Inventor of SLA 3D Printing stated, "The only limit to 3D printing is your imagination. You can literally design the future."

Perfecting Your 3D Printed F1 Car: From Printing to Post-Processing

To perfect your Formula 1 3D printing, follow a few post-processing steps:

Printing Intricate Parts

While recreating complex components of an F1 car, like the wheels, chassis, and aerodynamics parts, an eye for detail is the answer. So, employ a large-resolution setting to trap the subtleties of every part.

The firm metal frame and straight extrusion capacities of Ender-3 V3 grant for accurate filament installation. However, the K2 plus’s high accelerations and big build volume serve numerous components immediately.

Assembly and Detailing

Following the printing set up the components attentively. Firstly, check out every part to confirm precision prior to the last draft. Typically, you might need glue for a few connections and a little sanding may be required to attain a flawless texture.

Real-World Applications and 3D Printing Innovations in Formula One

Certainly, 3d printing has established its validity for Formula 1 cars, as teams growingly relying on the chiefs in this innovation to upgrade their productivity. Famous instances involve Red Bull Racing, Constructor’s Champion following 2022, which has been collaborating with Hexagon Manufacturing Intelligence for 18 years.

Also, Scuderia Ferrari and Mercedes-AMG Petronas diligently use 3D printing to improve their vehicle’s execution. The particular teams exercise the technology to generate lightweight, more complicated components vital in Formula 1 racing. Parts such as mirror housings, brake ducts, and aerodynamic pieces are mostly printed at once on the running tracks.

This power permits fast modeling and personalization to reach particular race requirements and needs. The incorporation of 3D printing in Formula 1 revised the way teams add vehicle outlines and testing.

Troubleshooting Common Printing Issues

While printing definite prototypes such as 3D printed F1 cars, you could face particular difficulties. For instance, bad layer sticking, deforming, or incorrect details. Of course, these issues can give up the model’s looks and durability.

If you want to manage these problems, firstly make sure that the printer is properly balanced and the print bed is even. Then rearrange the printer settings such as print pace, and temperature depending on the medium utilized.

For example, boosting the bed temperature can aid in lowering twisting, however, minimizing the print pace may enhance detail precision and coating bonding.

Conclusion

The possibility of producing 3d printed F1 car unlocks a stimulating prospect for hobbyists and sculptors, fusing a dedication for racing with the advanced innovation of 3D printing. With the usage of comprehensive designs and accurate printing abilities, everyone can recreate the briskness and sophistication of Formula 1 cars. Even if for academic reasons, hobby tasks, or expert pursuits, 3D printed F1 cars act as proof of the improvements in additive manufacturing and automotive engineering. Don’t forget to explore the landscape of 3D printing with your particular F1 car task. Dive into the Creality’s variety of modern 3D printers, ideal for composing thorough and complicated models. Welcome the difficulty and thrill of 3D printing to breathe new life into your dearest F1 cars with Creality.