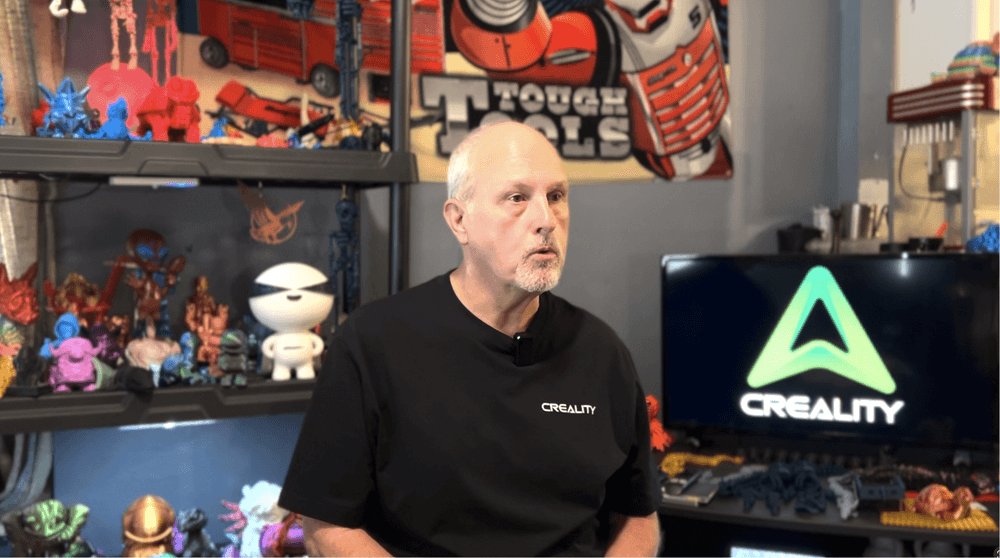

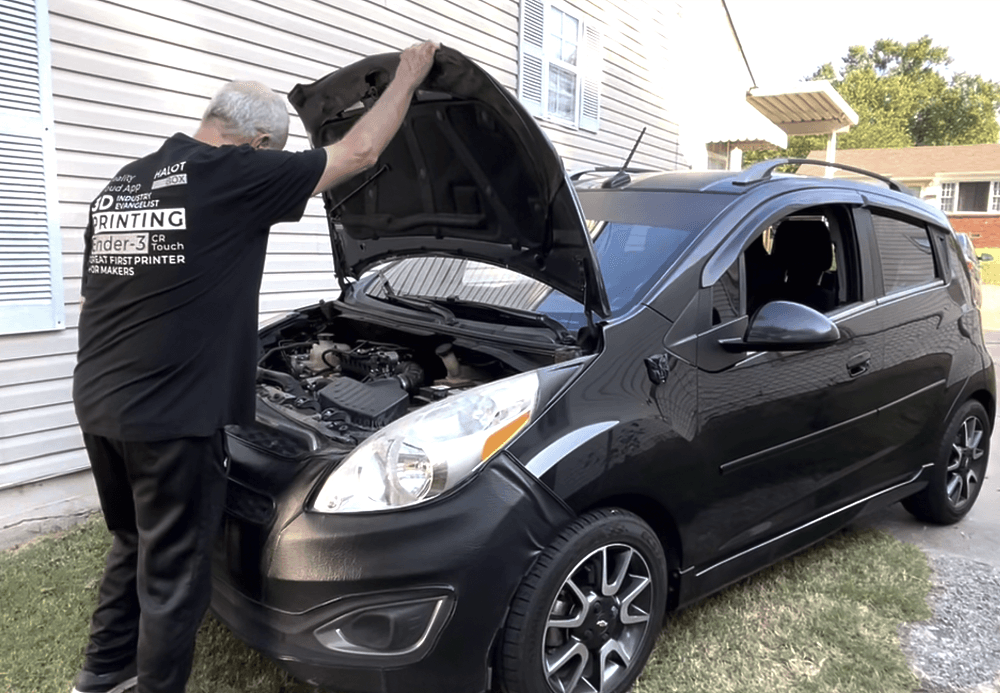

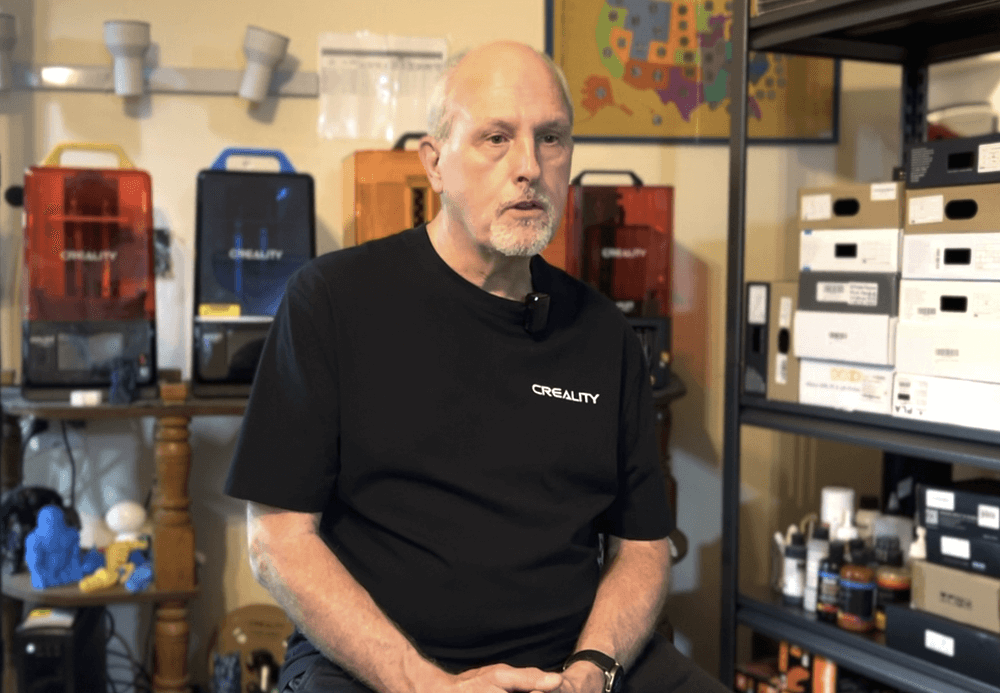

Lee Durham, a 64-year-old retired automotive technician living in the southern United States, is a highly respected expert within the Creality user community. With over twelve years of experience in 3D printing, he owns more than ten Creality printers at home—ranging from the Ender-3 Pro to the K1 Max and Creality Hi—representing a total investment of over $20,000. Together, these machines form a comprehensive personal print farm. As one of the community's early members, Lee has been actively involved in multiple technical groups, consistently offering support to new users. Over time, he has come to be regarded as both a maker mentor and a trusted guide within the 3D printing community.

Lee in his home workshop, surrounded by 3D-printed creations

Usage Scenarios and Pain Points

Before 3D printing entered his life, Lee was facing one of the loneliest and most uncertain periods he had ever known. After a divorce, he felt as if he had lost almost everything his marriage, his home, and much of his sense of purpose. Retirement was approaching, but instead of being a time to enjoy life, it felt empty and without direction.

Lee had always enjoyed making things by hand, and he hoped this could be a way to spend more time doing creative projects together with his son. In the past, they had worked with traditional materials, but these came with limitations many of their ideas couldn’t be realized due to material constraints and the complexity of shaping them. It was during this period that his son bought him his first 3D printer. 3D printing changed that entirely, offering them a tool that could turn even the most imaginative concepts into tangible creations.

What began as a way to reconnect with his son soon became a vital part of Lee’s daily life. The learning curve was steep, but the challenge gave him focus and motivation at a time when he needed it most.

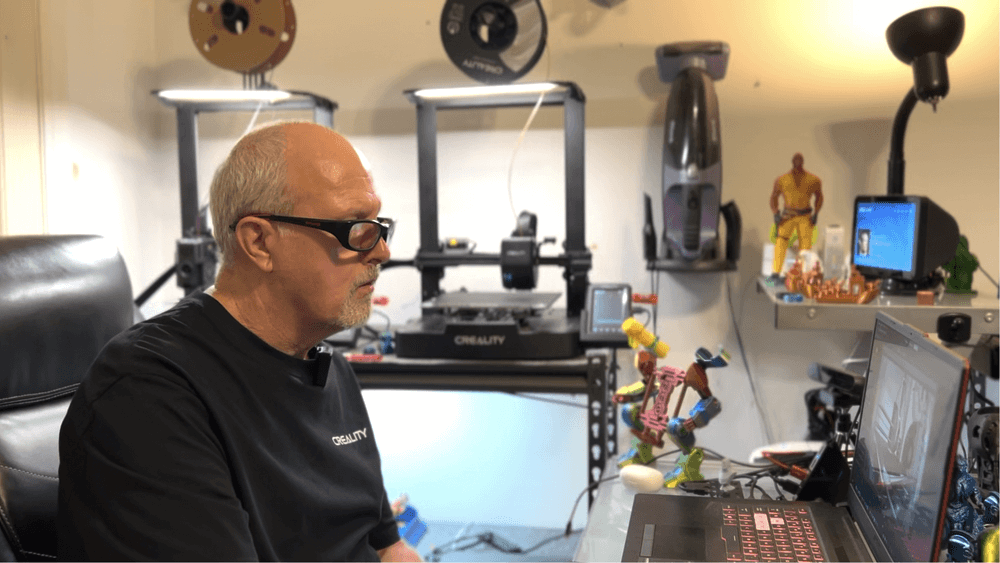

Running his multi-printer setup for daily production

Lee maintains his passion for cars

Product Solution

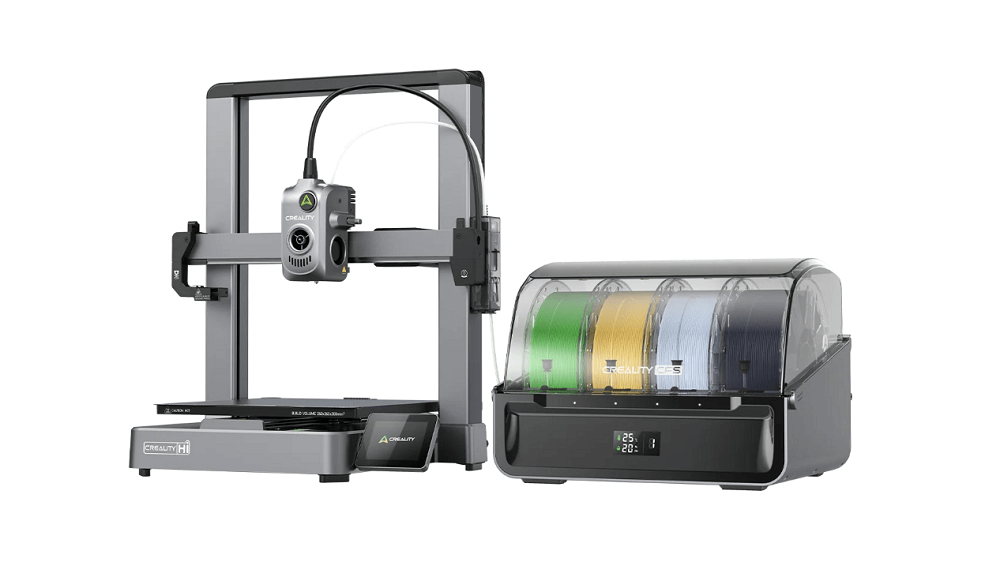

As Lee delved deeper into 3D printing, he built a comprehensive setup of machines and workflows. His main workhorses are the K1 Max and Creality Hi, both upgraded with CFS multi-color systems to support high-quality multi-color model production. In addition, he operates multiple V3, V3 Plus, and K1 series machines, which are designated for single-color parts, carbon fiber prints, and other daily tasks. These machines run almost continuously, each with a clearly defined role, forming a well-structured home-based print farm.

On the software side, Lee primarily uses Blender in combination with AI tools for creative modeling, and then relies on Creality Print for slicing and task distribution. This streamlined workflow ensures efficient and reliable production. With years of hands-on experience and dedicated maintenance routines, Lee has progressed from a novice to an expert in multi-machine operation. The plug-and-play usability of Creality devices, along with modular maintenance design and strong material compatibility, has provided him with a stable and scalable environment for continuous creation.

Results and Value Presentation

Lee’s machines run nearly nonstop year-round, producing an average of three to four models each day—and sometimes even more. He recalls, “I’ve probably printed thousands of models. I’ve run out of space at home. I have to box some of them up just to make room for new ones.” His creations range from small figurines to large collectibles, many of which are proudly displayed throughout his home for visitors to see.

According to Lee, the value of this work goes far beyond the occasional income it brings.

Detailed dragon models with vivid colors

Poseable Marvel-inspired figures

Display shelf of hundreds of 3D-printed works

Sharing his journey with the Creality community

I really couldn’t tell you how much money I’ve spent. But it’s not about the money. It’s about the joy. It’s about doing something you truly enjoy.” Said Lee

Conclusion

Lee’s story illustrates a replicable path of growth—from passion-driven exploration to technical mastery, and ultimately to giving back to the community and inspiring others. His journey shows that Creality offers more than just cost-effective 3D printers; it provides a complete ecosystem for user development—spanning hardware, support, community, and emotional connection—designed to support individuals at various stages of life.

Today, Lee also serves as an “expert” in several Creality user communities, helping newcomers troubleshoot and share best practices. He sees this role as part of “helping others complete their journey,” and adds, “It gives you the motivation to wake up and say, ‘What am I going to print today?’ That’s the feeling 3D printing gives you.”

In today’s rapidly growing maker culture, individual creators like Lee are becoming key drivers of technology adoption and community value. His experience not only reflects the broad potential of 3D printing but also opens the door for others to rediscover purpose and joy through the act of creation.