Nestled in Yuncheng, Shanxi Province, ThumbsUp 3D is reshaping how custom 3D printing is done at scale. From educational tools and medical models to custom toys, this professional 3D printing farm runs like a well-oiled factory — powered by over 1000 Creality Ender-3 V3 PLUS machines. With international clients relying on both quality and speed, ThumbsUp 3D has built a reputation for delivering reliable, high-volume custom production.

Usage Scenarios and Pain Points

ThumbsUp 3D primarily caters to international clients with a need for large-batch customization. Their core offerings include STEM teaching kits, medical demonstration tools, and functional toys. To stay competitive, they must handle diverse product types, tight lead times, and maintain consistent output quality.

However, scaling up came with growing pains. Existing machines couldn’t keep up with rising demand. Frequent maintenance, inconsistent prints, and the complexity of managing large workflows — from ventilation to order scheduling — became major roadblocks.

To truly understand the diversity of their output, here are a few real-world examples from ThumbsUp 3D’s print farm.

Product Solution

Why Creality: A Scalable, Reliable Production Backbone

To address these challenges, ThumbsUp 3D turned to Creality. The brand's reputation for reliability and comprehensive after-sales support gave the team confidence. More importantly, the V3 PLUS model proved to be a perfect match for the print farm format. It offers high stability, print precision, and is easy to maintain — all crucial for 24/7 batch production.

To better illustrate the print capabilities and material versatility of the V3 PLUS, here’s a breakdown of common use cases from ThumbsUp 3D’s operations:

Ender-3 V3 Plus 3d Print Configuration Recommendations

USE PLA / PLA+ / Rainbow PLA

- Filament Type: PLA / PLA+ / Rainbow PLA

- Print Application: Toys, Educational Kits

- Print Quality: Smooth surfaces, consistent layer bonding, ideal for batch output

USE Wood-filled PLA

- Filament Type: Wood-filled PLA

- Print Application: Decorative Gifts, Artistic Parts

- Print Quality: Fine texture and excellent detail, natural grain-like surface

USE Matte PLA / Color PLA

- Filament Type: Matte PLA / Color PLA

- Print Application: Functional Prototypes, Presentation Models, Medical Demonstration Tools

- Print Quality: Matte finish, clear edge lines, high dimensional stability

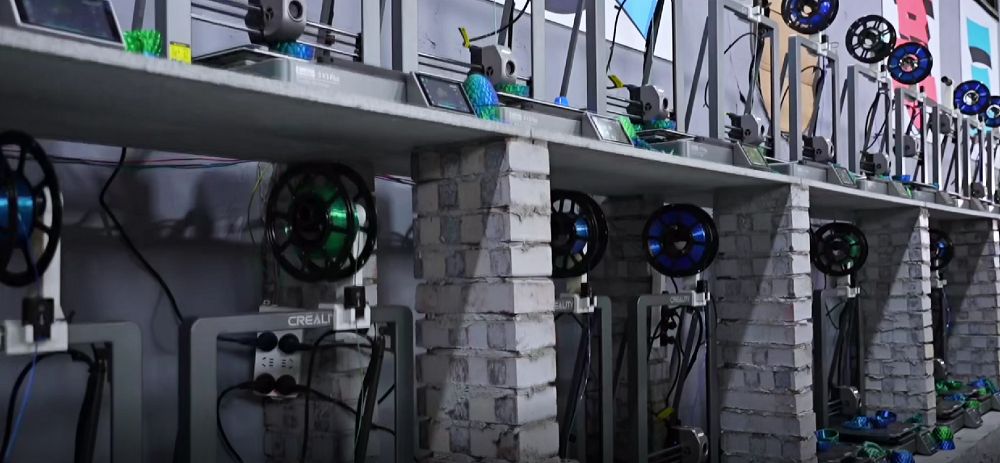

Currently, ThumbsUp 3D operates over 1000 V3 PLUS units across a 600 to 700-square-meter facility. The farm is split across two floors and six dedicated printing zones. Each printer is placed on a custom-built brick and stone platform, a design choice that has greatly improved mechanical stability and part accuracy. To ensure consistent operation and prevent hotend clogs, six negative pressure fans were installed to optimize heat dissipation throughout the space.

To streamline logistics, separate areas have been designated for filament storage and printed parts. Meanwhile, modeling and slicing tasks are handled by a remote team in Taiyuan, allowing production and design to remain decoupled but synchronized. This workflow greatly improves efficiency, reduces idle time, and ensures accurate execution across the entire production chain.

Results and Value Presentation

The results speak volumes. ThumbsUp 3D has successfully transformed from a growing service provider into a full-fledged print manufacturing hub. With over 1000 printers running simultaneously, their production capacity has increased dramatically. The wide variety of parts they produce — from STEM teaching kits to rehabilitation tools — consistently meets quality expectations. This has led to high customer satisfaction and an increase in repeat orders from international clients.

By optimizing the entire process — from equipment layout to ventilation, task delegation, and centralized material management — the company has also minimized manual intervention, reduced production downtime, and ensured a smooth, scalable operation. Thanks to this fully optimized print-farm workflow, ThumbsUp 3D has achieved not only stable output but also substantial commercial success. Based on their machine fleet size and continuous production model, the company now delivers over 1.5 million parts per year, with an estimated annual revenue ranging from USD 6 million to 10 million. This positions them as one of the most productive and profitable 3D printing farms in China — entirely built on Creality’s scalable hardware.

Conclusion

A Scalable Blueprint for Print Farm Success

ThumbsUp 3D’s success highlights a new model for decentralized production, where 3D print farms can serve as industrial-scale manufacturing centers — without the need for traditional molds or factories. With the right hardware, layout strategy, and workflow, a modern print farm can be both agile and powerful.

Creality’s farm-ready solutions make this possible — not just through robust hardware like the V3 PLUS, but by enabling visionary businesses like ThumbsUp 3D to scale their ambitions with confidence.