Who doesn’t love a piece of jewelry? From a wedding proposal ring to a fancy, precious bracelet, jewelry has always been a part of personal adornment across the globe. Traditional jewelry-making, however, is expensive, slow, and limits creativity. This means that many people never had a chance to get into the industry, but not anymore! With the advancement of 3D printing, a lot has changed.

Across all categories of jewelry making, 3D printing could be exploited to fast-track the process and introduce fresh ideas. 3D printing jewelry allows unmatched design freedom, fast prototyping, and cost-effective customization.

If you are out there wondering if 3D printing jewelry is realistic for hobbyists or only ideal for professionals, tag along as we dive into the finer details of 3d printed jewelry.

How 3D Printing is Changing the Jewelry Industry

To understand why jewelers are turning to 3D printing, we have to review the traditional methods of jewelry making. From hand-carving to mold casting, jewelry making has been a labor-intensive process for many years. Moreover, these processes were often closely guarded, with only a few artisans being capable of fulfilling commissioned orders flawlessly.

Traditionally, an artisan had to do much of the work manually, from sketching a design to building prototypes and molds. With 3D jewelry making, however, the process has been disrupted to allow designers to use computer programs to build even more detailed designs and even build the prototypes in minutes. And the best part is that you can make almost all kinds of jewelry this way.

What’s possible now that wasn’t before?

A lot has become possible in the era of 3D printing for jewelry. For instance, you can now make super tiny, detailed designs that were and still are quite hard to do by hand. As a result, making items like twisty rings or name pendants is way easier now! Our FaIcon A1 laser engraver is also capable of name engraving.

And with jewelry design with 3D printing, you just draw it on a computer and print it out. When the computer-aided design (CAD) is combined with digital jewelry prototyping, you get to try it, change it, and try again without wasting stuff or starting over each time.

How Jewelry Goes from Idea to Wearable

With a 3D printer, a ring or earring goes from a sketch in your head to something you can actually wear through a simple process.

It all starts with a digital design. This is where you start building your idea on a computer using simple 3D software (like TinkerCAD, Blender, or RhinoGold). This step lets you add fine details, such as a tiny swirl, a curve, or a custom engraving. It’s worth noting that these details are super hard to carve by hand.

From the design, you can now print a prototype. Instead of waiting weeks for a jeweler to carve wax or metal, you just print your design in high detail using a resin 3D printer such as the Creality HALOT-MAGE PRO. If the size feels off or a part looks weird, you just go back, tweak the design, and print a better version. This is called digital jewelry prototyping, and it saves you time and makes mistakes less costly.

Once you're happy with your jewelry, you make a resin print that works as a mold for casting in metal. Sometimes, you could settle for it as the final piece, especially if you were only making artistic or fashion jewelry.

3D Printing Methods for Jewelry: Which Path Should You Take?

A. Direct 3D Printing

Not every piece of jewelry has to be made of metal. Sometimes you want bold, fun, fashion pieces, like colorful earrings, chunky bracelets, or creative shapes that grab attention. That’s where direct 3D printing comes in.

Direct 3D printing means you print the actual jewelry piece as it is, no casting, no molds, no extra steps.

But can you print jewelry in plastic or metal directly? Yes. You can use a plastic jewelry 3D printer to create finished pieces, especially for fashion or costume jewelry. You just need the right filament and a good printer, such as the Creality Ender-3 V3 KE.

For plastic designs, FDM printers work great. You can use filaments like PLA, PETG, or even flexible TPU to get different looks and feels.

Direct metal 3D printing, on the other hand, uses advanced machines like binder jetting or DMLS (Direct Metal Laser Sintering). These machines, however, cost a lot and need a serious setup.

B. Print-to-Cast

So, let’s say you want a real gold ring or a shiny silver pendant, not just something plastic. This is where the print-to-cast method comes in. It uses a process called lost-wax 3D printing.

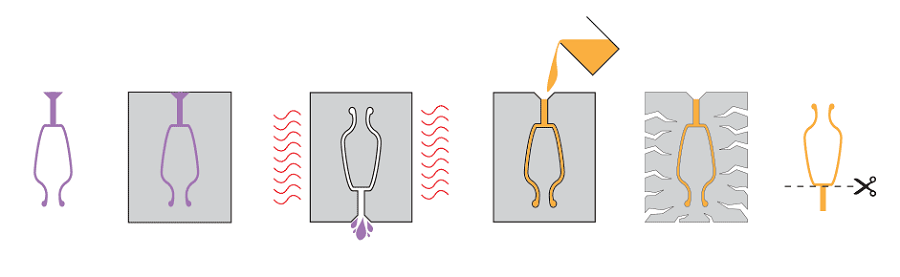

First, you design your jewelry on a computer. Then, you print it using a castable resin for jewelry. This special resin is made to melt cleanly later, just like wax, leaving no mess or gunk.

Here’s a step-by-step breakdown of how you’ll make it work:

-

Design it

-

Print it with resin

-

UV cure it to make it strong

-

Put it in a mold

-

Melt the resin out (that’s the “lost” part)

-

Pour in metal

-

Let it cool

-

Polish your final piece

This process is called resin jewelry casting, and it lets you turn your idea into a real metal piece without needing to carve wax by hand or use expensive tools.

Common Pitfalls When 3D Printing Jewelry (and How to Avoid Them)

Before getting into 3D printing, it’s imperative to note that some prints might fail or come out rough. These shouldn’t discourage you because most beginner mistakes are easy to fix once you know what to watch for.

1. Designing walls that are too thin

Jewelry needs to be delicate, but if your walls are too thin or have unsupported overhangs, your print might collapse or break. For resin prints, aim for at least 0.4–0.6 mm wall thickness. For FDM plastic jewelry, go even thicker.

2. Skipping post-processing

All resin prints need to be washed and cured after printing. If you skip washing, they stay soft or even sticky. Use a Creality Curing & Washing Station. It helps you clean and cure your resin jewelry properly, which means smoother finishes devoid of weird smears or gooey edges.

3. Choosing the wrong resolution

Details matter in jewelry. If you’ve included really small text, filigree, or textures, you’ll need high resolution. If you print too fast or use a low-res setting, your jewelry will look blobby or unfinished.

Use your slicer’s fine-detail mode to get those crisp edges.

4. Messing up resin exposure

When working with resin, too much light exposure will make your print brittle. Too little? It’ll stay soft or droopy. As such, always check your resin’s profile and follow Creality’s slicing guide for best results.

5. FDM stringing and blobbing

If you're using an FDM printer for plastic jewelry, you might encounter “strings” or blobs, an indication that your retraction settings are off. This fault is fixable with a little slicer tuning.

What Can You Print and How to Start Without Breaking the Bank

So, what kind of jewelry can you actually make with a 3D printer? And can you really start without spending a fortune? Well, the short answer is yes.

What types of jewelry are ideal for beginners?

The best place to start is with simple, custom-printed rings, basic 3D printed earrings, and pendants with initials or patterns. These will give you easy wins because you get to test your skills, materials, and printer settings without stressing over complicated builds.

Can you do mixed-material or gem-set designs?

Yes. You can start by printing stone holders and gluing in gems afterward. From there, you could combine FDM-printed plastic bodies with metallic paint or even embed small metal parts.

How do you start on a budget?

Professional jewelry setups can cost $2,000 or more, especially with metal printing or high-end castable resins. For jewelry printing beginners, however, there’s a smarter path:

Step 1: Design your piece using free CAD software

Step 2: Print the prototype at home using a resin printer

Step 3: Outsource the final casting to a local jeweler or service like Shapeways

This method saves you money and gives you full control over the design.

FAQs: Jewelry 3D Printing

Can I 3D print gold or silver directly?

Not at home. Resin and filament jewelry is more accessible for beginners. If you want gold or silver jewelry, print the piece in castable resin and have it cast at a jeweler.

Is 3D-printed jewelry durable?

Yes! Resin prints are great for detail, while filament-based jewelry (like PLA or PETG) is more impact-resistant. Note, however, that post-curing and sealing make a big difference.

What resolution should I use for earrings or pendants?

For fine jewelry, go with 35–50 microns on resin printers. Lower resolutions can cause blurry or melted-looking details.

How do I add textures or engravings?

Use engraving features in jewelry CAD software like Blender or RhinoGold. Textures can be modeled in or applied as bump maps before slicing.

Do 3D printers print gemstones too?

No. But you can design stone holders into your prints and manually set real or fake gems afterward.

Conclusion: Your Jewelry Journey Starts Here

3D printing is a gateway to custom, creative, and even professional jewelry making from the comfort of home. Whether you’re sketching your first ring or planning a small side hustle, all you need is an idea and a printer to bring it to life.