How responsible technology restores dignity, confidence, and independence for people with limb differences, Ayúdame3D is partnering with Creality to set a powerful example of how accessible innovation can change lives. Through the Changing Lives initiative, the partnership has scaled Ayúdame3D’s mission, leveraging low-cost 3D printing to create life-changing prosthetic arms, into the world’s first social 3D printing farm. Across more than 60 countries, from Madrid to Nairobi, Manila to Lima, thousands are regaining mobility, returning to school or work, and rewriting what’s possible in their futures.

A Spark of Hope: One Volunteer Trip That Changed Everything

Ayúdame3D is a Spanish organisation that believes in the potential of 3D printing technology to change lives and create a more inclusive world.

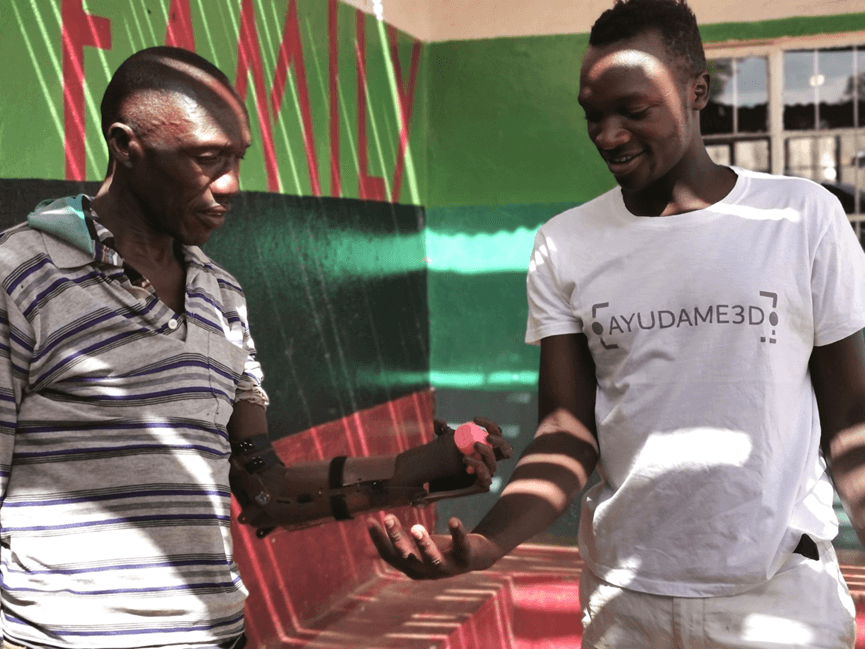

Since Ayúdame3D’s founding in 2017, Guillermo Martínez and his team have pursued a single purpose: to apply accessible technology for the greater good. That volunteer journey began with a trip to Kenya, where Guillermo delivered five 3D-printed arms. Seeing how just a few hours of 3D printing could improve lives in a faster, simpler and more affordable way compared to traditional prosthetics, he was convinced to do more. Today, Ayúdame3D designs, prints, and freely distributes over 250 prosthetic arms annually, reaching people who would otherwise have no access to functional limb replacements.

A Shared Vision: Democratizing Prosthetics Building Through 3D-Printing

Traditional prosthetics often cost thousands of dollars and take months to produce. In contrast, Ayúdame3D’s modular, 3D-printed designs can be tailored and delivered within days at a significant reduction in expense. At the core of this breakthrough is Creality’s reliable desktop 3D printer. Over the past six years, Creality has been empowering this ‘Changing Lives’ project with the donation of a wide range of machines—from early CR-10 smart to the high-speed K1 Max, empowering Ayúdame3D to expand quality control, boost production, and maintain consistency across its global workshops.

“When we saw how quickly and cost-effectively 3D printing could restore someone’s independence, there was no turning back.”

— Guillermo Martínez, Founder of Ayúdame3D

Inside the World’s First Social 3D-Printing Farm

Operating out of Madrid’s La Nave innovation hub, Ayúdame3D runs more than 50 Creality 3D printers in a continuous workflow. Each prosthetic is printed in modular lightweight parts, assembled, and customised for the recipient. The high-speed Creality K1 Max, known for its precision and reliability, plays a key role in scaling consistent prosthetic production. Volunteers and engineers apply lean manufacturing methods adapted for impact, including digital slicing of schedules, colour-coded parts, and skill-sharing programs. This working model is now being replicated in workshops called ‘3Dlabs’ across East Africa, Southeast Asia, and South America, equipping local communities with this leading technology. Creality’s contributions extend beyond hardware: training, firmware support, and supply-chain optimisation all play a critical role in sustaining these attempts of kindness.

Watch this video to find out how Ayúdame3D and Creality utilise this workflow to change lives:

Changing Lives: Real People, Real Stories, Real Impact

Behind every arm printed in the farm lies a person reclaiming control over daily life. In Kenya, a teacher named Philip, who had never held a chalk and a book simultaneously until the age of fifty, now conducts lessons with renewed enthusiasm. In Peru, a young woman re-entered the workforce in an office environment after years of being sidelined due to limited manual dexterity. And in the Philippines, a student returned to her computer science classes, tapping code with both hands again. These stories highlight how lightweight, adjustable 3D prosthetics meet everyday needs, like comfort, usability, and personalisation, where traditional devices often fall short.

To mark ten years of transforming ten lives, Creality renewed its support through a second donation of printers for the project. These units not only expand Ayúdame3D’s current working capacity but will also be passed on to local Spanish schools after, encouraging the next generation of socially conscious makers. Each prosthesis is more than a device—it’s a turning point. From Saitemu in Kenya, where he is now able to hold his schoolbooks and write, to professionals and students regaining career and academic momentum, these stories highlight the human side of innovation. They are shared widely on social media to inspire, educate, and advocate.

On May 7th, King Felipe VI visited Ayúdame3D’s 3D printing workshop at Madrid’s La Nave Innovation Centre. Guillermo Martínez showcased how Creality printers are used to produce custom prosthetic arms, explaining the 6-year collaboration. The King even attempted to print a prosthetic finger on a Creality K1 Max, highlighting the powerful impact of technology for social good.

Looking Ahead: Why ‘Technology for Good’ Matters

With a solid foundation in prosthetics, the team is already developing lightweight exoskeletons and assistive mobility devices, using the same modular, cost-efficient 3D printing strategy. Meanwhile, 3Dlabs continues to expand, becoming hubs for STEM education rooted in social purpose. This collaboration is more than just a project. By centring beneficiaries over “users,” and “people with limb differences” over “the disabled,” Ayúdame3D and Creality are reshaping this philosophy of how innovation is defined and deployed. Each device produced, each life changed, is a testament to what ethical, inclusive, and purpose-driven technology can truly achieve.