As 3D printing becomes more popular, it is important to address concerns about the toxins released during the process. 3D printing technology is changing businesses, starting with medicine production. It offers great flexibility and speed in bringing new ideas to life.

But as this new gadget becomes common in homes and offices, it raises an important question: “Is 3D printing toxic ?”.

Today's post will look at the health risks of 3D printing. We will focus on the fumes released during printing. We will also provide tips on best practices. This will help users experiment safely.

Understanding 3D Printing Fumes

Before we delve into the dangers of 3D printing and 3D printing safety, let’s first understand 3D printing fumes.

What are 3D Printing Fumes?

3D printing fumes usually contain a mix of ultrafine particles (UFPs) and volatile organic compounds (VOCs). They release during the melting of filament materials.

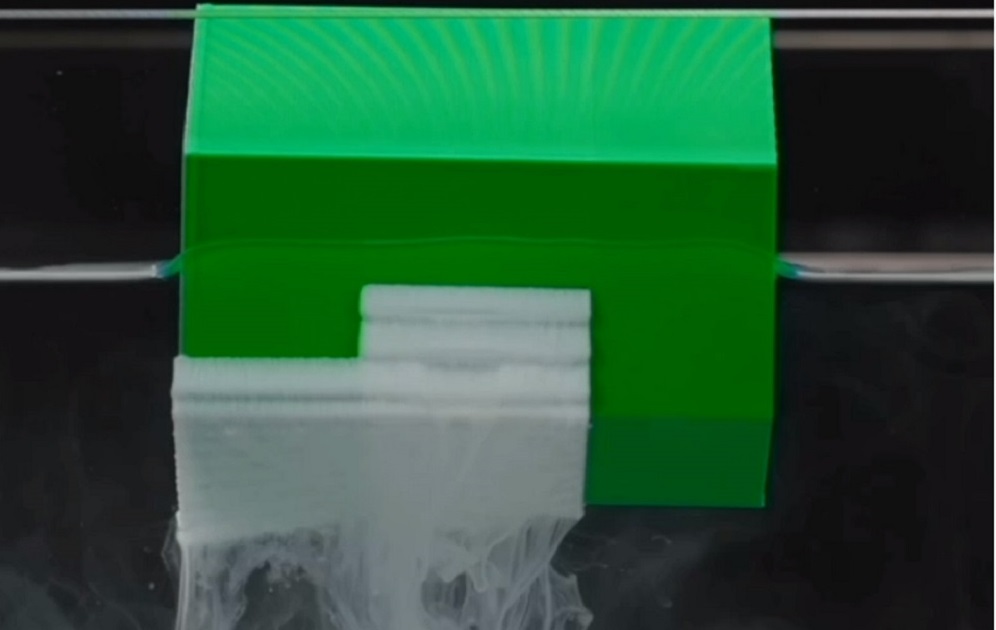

The printer heats the filament until it melts. Then, it discharges the melted material layer by layer.

Formation of Fumes

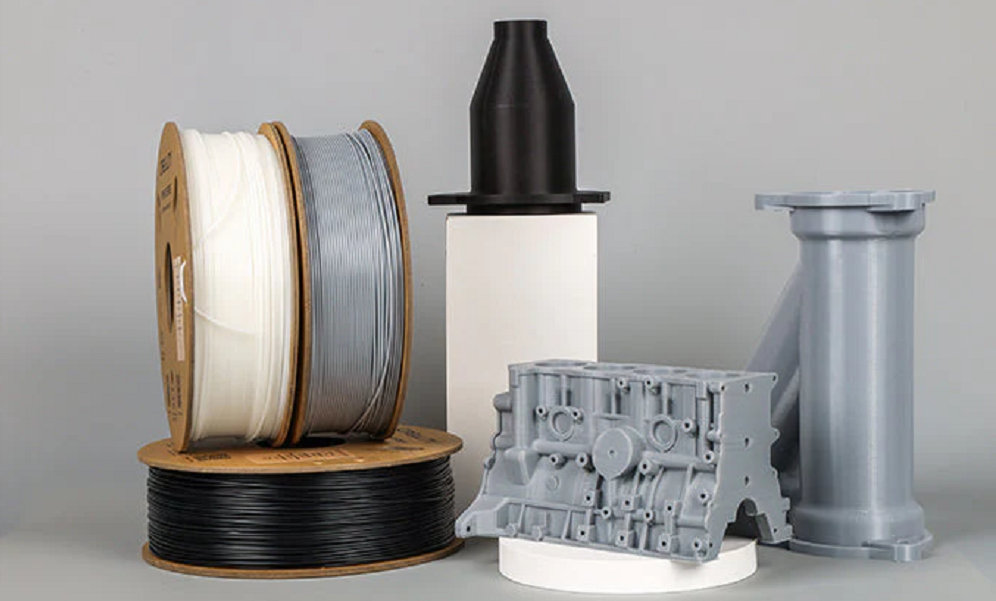

Regular 3D printer "ink," called filament, is a polymer. The process dissolves it during printing to create the needed 3D item. Several types of filaments are available to choose from. The most popular ones are PLA, ABS, and PETG.

While 3D printing, manufacturers heat these materials to temperatures ranging from 190°C to 260°C. This heating method leads the materials to release gases as their components collapse or react with the air.

Common Emissions

Most often, the fumes released in 3D printing involve a mixture of chemicals and small particles:

- Styrene: Mainly from ABS, recognized for its powerful, acidic smell.

- Formaldehyde: An evil-smelling gas, ranked as a carcinogen, discharged from warmed-up PLA.

- Ultrafine Particles (UFPs): Small particles that can deeply creep into the lungs and enter the blood flow.

Each of these discharges has different health risks from 3D printers. This raises important concerns about 3D printing safety and proper use, especially in poorly ventilated spaces.

Are 3D Printing Fumes Toxic?

Is 3d printing toxic? New research from the Environmental Protection Agency (EPA) and some schools highlights the dangers of 3D printing.

Studies have discovered that the 3D printing operation emits particulates and gases which might present health hazards to users.

The secretions contain VOCs, which are dangerous to human well-being when breathed in. Also, 3D printers can emit particles of micron size (1-100nm). These particles are too small to settle deeper into the respiratory system.

So, they can be further challenging to remove from the body as compared to bigger solid particles.

The National Institute for Occupational Safety and Health (NIOSH) discovered something important. Printing with plastic can release harmful gases and particles. This can put workers and others at risk. These can enter the lungs and cause health problems.

Material-Specific Toxicity

- PLA Filament: Is pla filament toxic? People mostly view PLA as the risk-free 3D printing filament, and it releases a candied corn-like odor when warmed. But, yet it emits ultrafine particulates that could cause respiratory concerns.

- ABS Filament: Recognized for its longevity and toughness, ABS discharges styrene, a harmful matter that possesses durable health impacts. Therefore, more dangerous than PLA.

- PETG Filament: PETG is between PLA and ABS. It has low toxicity and less smell. However, it still releases UFPs when printed.

- Resin: Resin is used in SLA (Stereolithography) printing. It can be harmful and release fumes. These fumes may cause eye and skin irritation. They can also lead to other health problems if not handled carefully.

Health Effects of Exposure

Breathing in harmful fumes from 3D printing can lead to many health issues. These include discomfort in the nose, eyes, and throat, as well as weakness and headaches.

They can cause long-term breathing and brain problems. This is especially true with long exposure to UFPs and VOCs.

Marilyn Black is the Vice President and has a Ph.D. at the Chemical Insights Research Institute. She said that pollution from 3D printers is similar to air pollution from cars. It is similar to sitting by a busy freeway.” Researchers associate this pollution with lung and heart disease or cardiopulmonary disease.

Comparing Different Filaments and Their Risks

PLA: Safety and Concerns

Typically, PLA is studied as a good choice because it’s created from natural origins such as corn starch. Mostly, PLA is celebrated for its environment-friendliness and minimum health dangers.

Nevertheless, the ultrafine particles it releases can even so present a danger, especially in poorly ventilated areas, highlighting the requirement for the right safety tips even while utilizing PLA.

ABS: Known Risks

ABS is a famous yet more problematic filament. Its discharge of styrene, a renowned dangerous air contaminant, classifies it among more toxic materials regarding chemical vulnerability. Besides, its fumes demand exceptional ventilation to prevent dangers when using a 3d printer.

PETG: A Safer Alternative?

Is PETG toxic to print? PETG provides a secure option to ABS, having hardly any unhealthy fumes. But, similar to all filaments, it still emits UFPs, turning ventilation into a key need for protection.

Resin: High Risk, High Reward

Resin 3D printing, though offering extraordinary perfection and detail for expert uses such as dentistry and jewelry, emits VOCs notably more dangerous than those from filament-based printing.

Therefore, managing resins demands masks, gloves, and preferably a devoted air purification setup to reduce health hazards.

Factors That Influence Toxicity Exposure

Here are some factors that can affect the toxicity exposure:

Printing Temperature and Emission Levels

The printing temperature whereupon your printer functions notably influences the release of ultrafine particles (UFPs) and volatile organic compounds (VOCs).

Excessive temperatures can make filaments such as ABS and nylon emit more dangerous matter. For example, the chance of decaying into harmful substances rises when substances are warmed up over their endorsed temperature range.

So, knowing and managing the functioning printing temperatures is key to reducing health issues linked with 3D printing fumes.

Importance of Ventilation

Good ventilation is crucial in reducing subjection to dangerous releases from 3D printing. Appropriate air flow aids in spreading and weakening airborne pollutants, lowering the collection of toxic particles in the breathing area of the working area.

Also, applying air purifiers with carbon-activated HEPA filters or exhaust setups can minimize the possibilities, confirming the air quality stays protected for workers and onlookers the same.

Impact of Printing Duration and Volume

The volume and period of 3D printing activities also impact vulnerability levels to germs. Constant exposure, in fact, to minimal levels of discharges, can gather and cause health problems with time.

Contrarily, brief subjection may not cause instant dangers when using a 3D printer but can turn controversial with regular printing episodes.

So, frequently checking the atmosphere for possible buildups of harmful matters and controlling printing timetables can help keep a protected printing activity.

How to Reduce the Health Risks of 3D Printing

3D printing safety is the greatest essence when running a 3D printer. Below are some helpful techniques to lower the 3D printer health risks:

Proper Ventilation Strategies

Enforcing efficient 3D printer ventilation is essential to reduce the threats related to 3D printing fumes. That said, unlocked windows can offer natural airflow; however, for confined areas or spaces having bad outdoor air interchange, fixing good exhaust systems is recommended.

Also, air purifiers furnished with activated carbon and HEPA filters can notably lower the gathering of toxic particles and VOCs in the air. Consequently, this makes the printing atmosphere secure.

Choosing Safer Filaments

The filament variety you purchase is key. However, the kind of filament also makes a difference. Selecting organic-origin filaments and low-VOC can significantly lower the possible health dangers.

Generally, filaments such as PLA are viewed as secure as they release fewer dangerous particles than resin or ABS. Makers are constantly making new filament ideas that emphasize protection without losing the longevity or quality of the prints.

Enclosures and Filtering Systems

An enclosure can efficiently keep particles and fumes, stopping them from sifting through the working zone. Several advanced 3D printers accompany fixed or elective enclosure gear that combines with filtration setups. Besides, while operating a printer, protect the foundation with a plastic covering before running.

Personal Protective Measures

While managing filaments and running 3D printers, dressing in individual protective gear like gloves and masks is advised, particularly when handling dangerous substances such as resin. The method helps avoid straightforward connections with toxic materials and lowers breathing risks.

Community Concerns and Common Questions

Can I 3D print in my bedroom?

Yes, it’s achievable; however not recommended in the absence of good ventilation and preventative measures in the area, particularly in cases utilizing filaments such as resin or ABS.

Are PLA fumes safe for pets and children?

Although PLA is among the secure substances, it yet releases UFPs that might be dangerous beyond the distant future or in badly ventilated areas.

What are the long-term effects of breathing in 3D printing fumes?

Prolonged subjection can cause respiratory irritation and other health issues, emphasizing the significance of good ventilation and secure printing methods.

Is PETG really a safer alternative to ABS?

Indeed, typically, PETG is harmless compared to ABS because of minimum toxic secretions, although it even so needs careful tackling.

What are the best enclosures and air filters for 3D printers?

Enclosures having built-in carbon and HEPA filters are very powerful at lowering vulnerability to dangerous releases.

Conclusion

3D printing technology provides huge opportunities in several sectors. However, it introduces special difficulties, specifically regarding possible dangerous exposures. Major results show that although a few filaments, such as PLA, are approved as secure, further, like resin and ABS, they need careful management because of their harmful discharges. So, sticking to strong precautions like using ventilation, choosing safer filaments and enclosures, and wearing protective gear is crucial.