“I’d love to come up with a process and package that the end user could scan their residual limb, take that mesh into meshmixer, apply a couple of templates, and be able to generate a socket and forearm cuff that they could then print in engineering grade plastic, nylon, CF-nylon etc.”

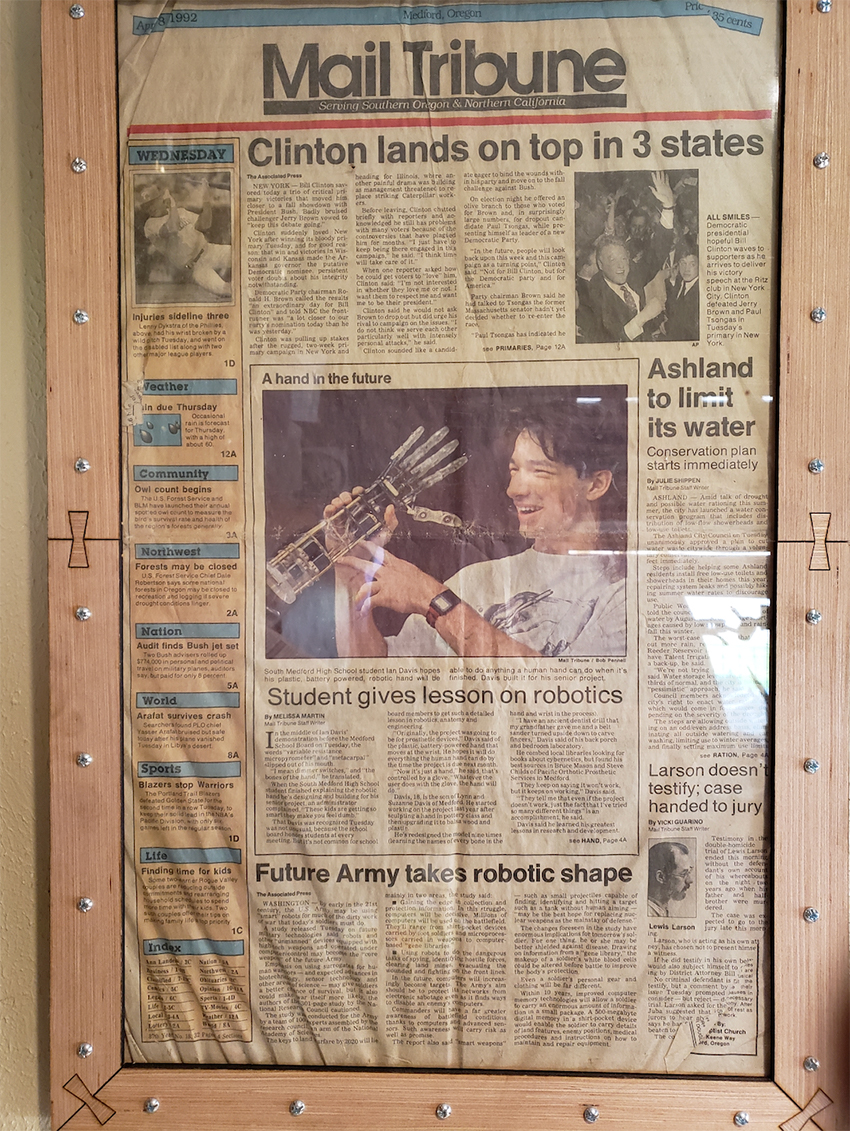

As a veteran 3DP user, Ian has been in engineering for three decades and is currently running a sheet metal shop in Oregon. He experienced a raft of 3DP products, typically for making partial hand prosthetics. As a project dating back to high school, this would prove to come in handy in an unfortunate way with a terminal illness befalling him later.

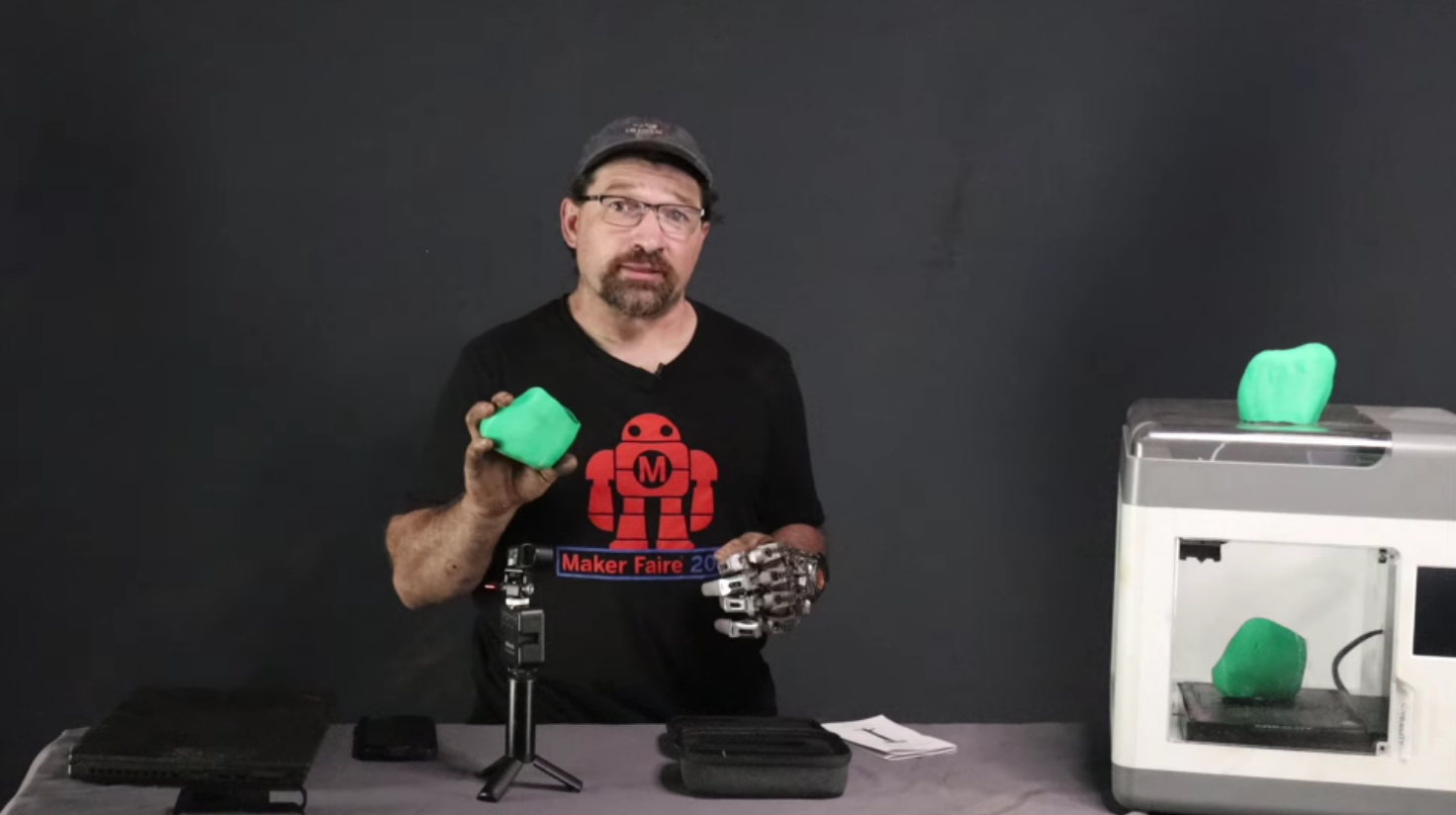

Ian also runs a YouTube channel about his project with 560,000 subscribers. Nowadays, Ian works on design iteration and machine programming during the day, and shoots videos at night for his channel as he aims to help more people in his situation with his designs.

Getting into hand-making and 3DP (and Creality)

Following his high school senior thesis, Ian designed and developed a fully ambulatory robotic arm using myo electronics in 1992, which, per himself, “was long before the advent of Arduino and the components that are available now.”

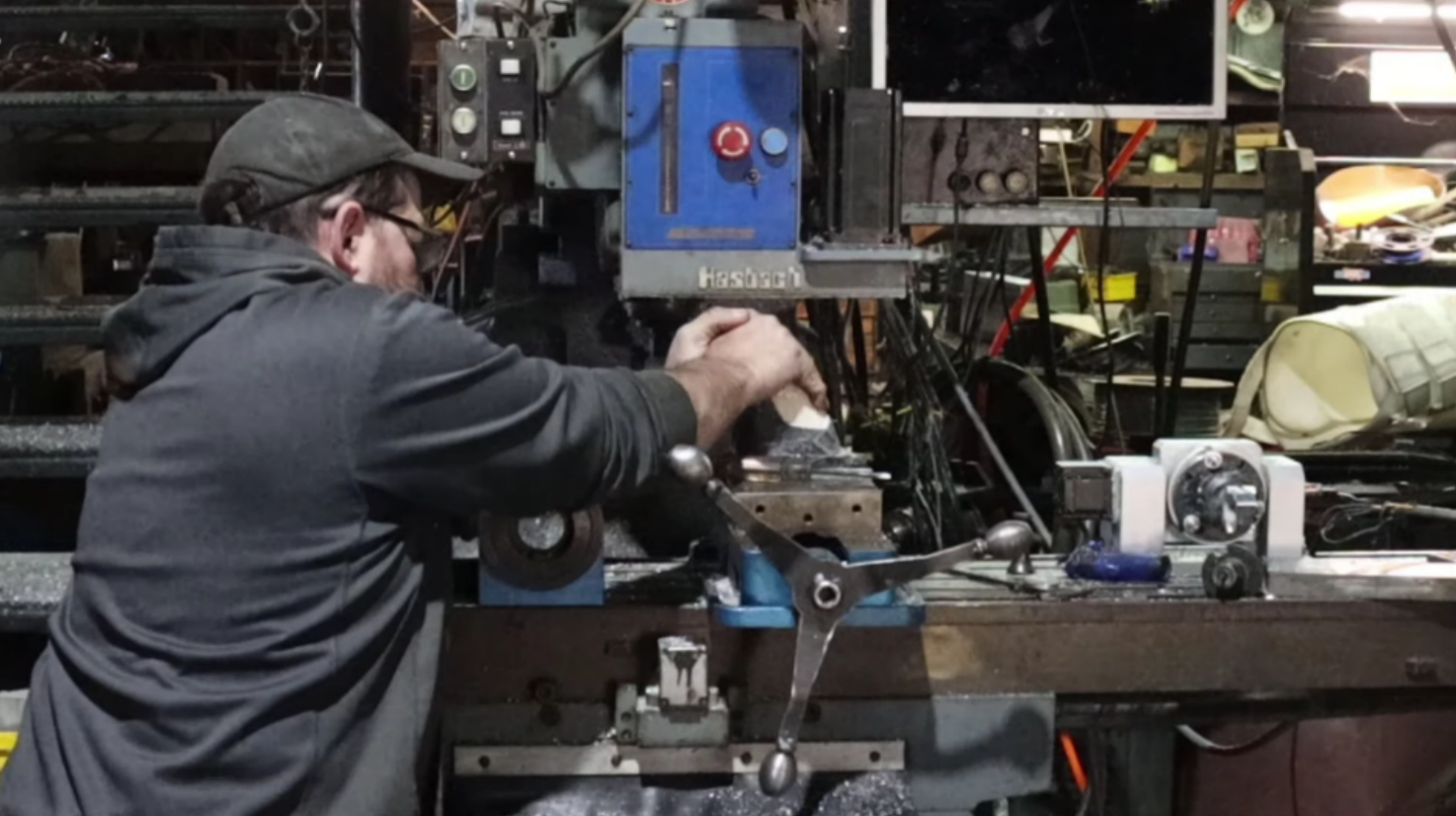

After graduation Ian started as an apprentice sheet metal tradesman and later set up his own shop, specializing in structural steel and ornamental iron products.

Then 2008 happened. He pivoted to bracket production and automation, starting to design and build conveyor assemblies and small automation cells alongside managing a Super Bowl stadium construction project.

This lasted for a decade, until the engineering craftsman was diagnosed with Multiple Myeloma and the cancer treatment led to the amputation of his fingers after breaking his dominant hand.

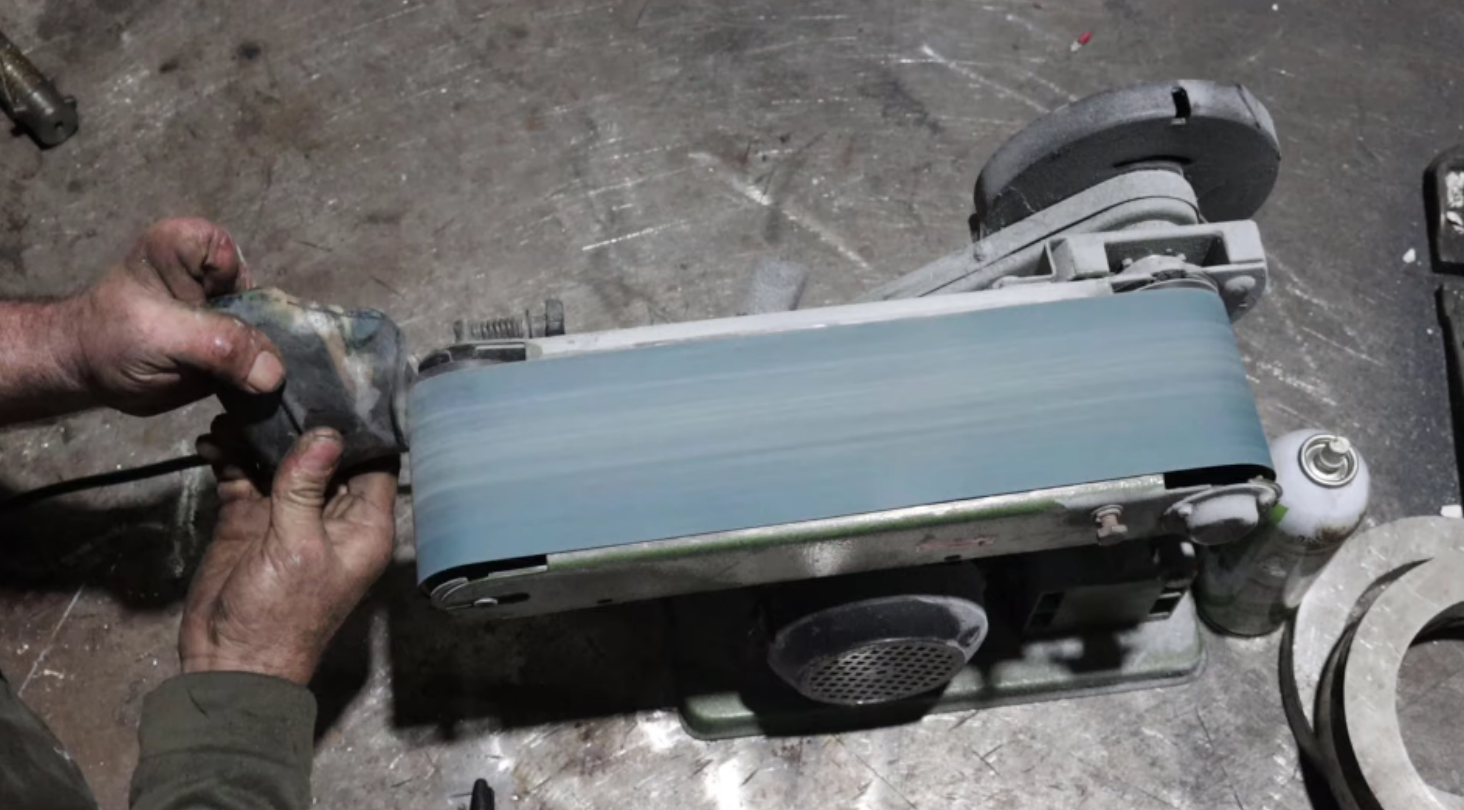

In recovery Ian started designing replacement parts for his hand. “My family brought one of my 3d printers to the hospital so I could start prototyping,” he recalls. Continuing the process back home till his first functioning device, Ian started sharing his progress on YouTube, where one of the videos went viral.

Later, starting from an early production unit Sermoon D1, Ian began his experience with Creality. Then he figured out his way with Sermoon V1 Pro, which has been reliable and works great for PLA and TPU, and HALOT-One Plus, finding the prime first layer time as well as the best areas for printing multiple parts.

For the CR-Scan Ferret 3D Scanner he has just got recently, Ian also built a hollow 4th axis that holds the scanner and small LED light. He raved about how accurately it works, “I've had amazing results with it so far and the scans scale pretty accurate to real life, with the socket fitting relatively well.”

As a hands-on person, Ian has also used Autocad since version 8 when it changes from command line to buttons.

Better DIY experiences and more affordable devices

“I have seen so much change since I got into additive manufacturing,” says Ian, who owns some of the earliest replicators in the industry. He was also a Kickstarter backer for the Peopoly Moai, which he calls “still a great printer”. He still thinks “there is a great need for alternative devices in the prosthetics sector.”

Once a professional device user, Ian reported paying with USD 80,000 from his insurance for a “neat but fragile” prosthetic approved by FDA, while the cost drops to USD 4,000 to have a 3d-printed device (if having a printer in place already, one could take another 1K off that number). And these 3d-printed kits are much more durable – they wear as long as 3 years according to the engineer.

Thus, Ian is trying to put together a DIY kit: “I’d love to come up with a process and package that the end user could scan their residual limb, take that mesh into meshmixer, apply a couple of templates, and be able to generate a socket and forearm cuff that they could then print in engineering grade plastic, nylon, CF-nylon etc.”

“Currently I have JLCPCB lined up to print the fingers, winder, and gimbal in stainless steel and PA-12. I have a series of videos on my channel detailing the vacuum resin process and how to cast the residual limb,” so goes Ian about his vision.

Taking the designs commercial would be ideal, but getting FDA approval could be a painful process. A company in Scotland dedicated to hand prosthetics wanted to hire Ian too, but that proves to be tricky too given the different nationalities and the distance.

At this moment, Ian puts his designs on Patreon for crowdfunding from those who need them. As he customizes designs for all walks of life, he has helped Mark, a guitarist and a golfer, back to music and his club again.

Speaking of how he expects Creality and the wider AM (additive manufacturing) industry to boost his project and DIY prosthetics, Ian remains hopeful: “it would be awesome to come up with a relatively easy, accurate, and repeatable process to generate a durable and long-lasting interface.”

Ian is also a member of e-NABLE, a global volunteering community using 3D printers to make free and low-cost prosthetic upper limb devices.

At Creality, we believe in realizing dreams.

Check out Ian’s project by visiting his site:

https://forgeprostheticdevices.com/

Watch and learn DIY hand prosthetics on YouTube:

https://www.youtube.com/@missingpartsclub/featured

Support Ian via Patreon:

https://www.patreon.com/IanDavis