With the progress of society and the development of science and technology, 3D printing technology is gradually replacing most of our traditional jobs. It has become an indispensable part of our lives. The future of the 3D printing industry is unlimited, so is the future of the 3D printing profession.

How would 3d printing be related to your future career?

3D printing is directly tied to future careers through its ability to:

-

Improve production efficiency: 3d printed products can reduce human involvement, optimize workflow and reduce production costs.

-

Promote innovation and creativity: 3D printing can achieve complex creative settings that were not possible with traditional methods before, and can customize products according to user needs.

-

Lowering production costs: 3D printing provides an economical and efficient alternative for small-scale manufacturing and innovation.

-

Improve medical equipment and quality of life: 3D printing can realize personalized printing of medical equipment, and can also provide printing of products supporting education and research.

3D printing can lead to new business models by enabling localized and customized manufacturing, transforming the way products are made and distributed.

The future of the 3D printing industry will have a profound impact on society by enhancing production efficiency, fostering innovation and creativity, lowering production costs, and advancing medical equipment and overall quality of life.

Common careers in the 3D printing industry

If you want to develop in the field of 3D printing, you need to know about three 3D printing jobs:

3d design

Although 3D printing products are often seen in our lives, if there is no 3D design profession, I think even if you have a K2 Plus in front of you, you can't print the product effect you want.

Therefore, the profession of 3D designer is a very popular 3D printing position. With them, we can turn our product ideas into reality and realize our 3D printing dreams.In crealitycloud we can find many 3d designers.

This type of position is mostly in some 3D printing companies or other 3D printing model design companies. You will work as a member of a creative team or as a freelancer.

In order to improve their own advantages, job seekers should have a good understanding of 3D modeling skills, understand the company's 3D printing technology, and have excellent design capabilities. Of course, they also need to have some other skills to help them complete the work content of 3D design.

3D Modeling jobs

3D modelers focus on creating and building three-dimensional models. Their main responsibility is to use modeling software to build accurate three-dimensional objects according to design needs and requirements. These models can be characters, environments, mechanical parts, etc., and mainly emphasize the shape, structure and size of the object.

Compared with 3D designers, 3D modelers focus more on the actual construction and detail optimization of models, ensuring that the structure, proportion and details of three-dimensional objects meet the design requirements and are suitable for practical applications such as animation, 3D printing or virtual environments.

Compared with 3D designers, 3D modelers need stronger technical skills and detail processing capabilities, focusing on how to accurately create three-dimensional objects to ensure that they meet design requirements.

3D printing operator

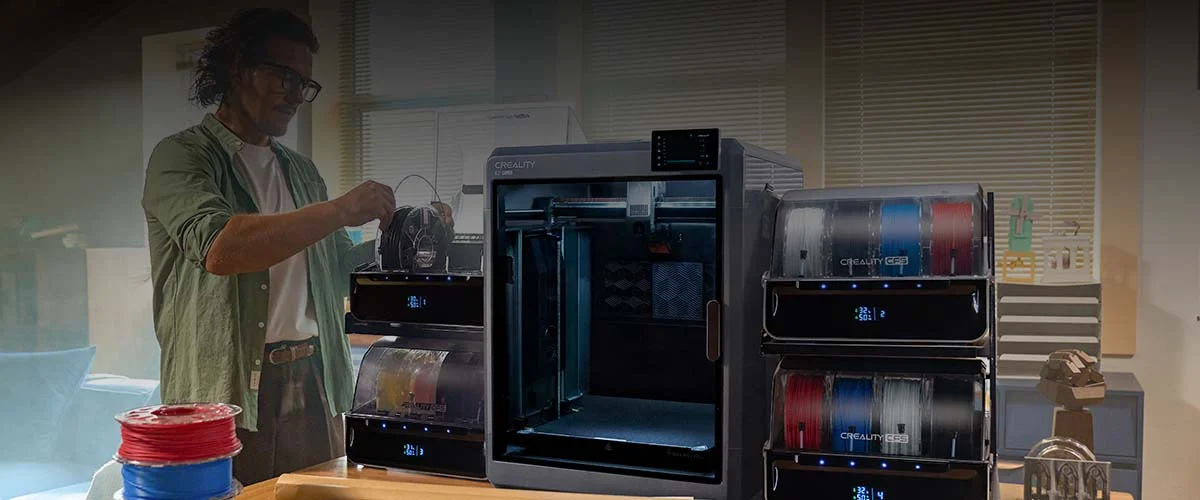

With the widespread application of 3D printing technology in industries such as industry, medicine, construction, and aviation, the demand for 3D printing operators continues to increase. This position provides good 3D printing career development opportunities for people engaged in 3D printing technology. Operators can advance to senior operators, equipment managers, and even enter the field of equipment research and development or technical support by continuously accumulating experience.

3D printing operators can create replacement parts quickly and efficiently, especially in the automotive industry. This technology enables the rapid production of customized car components tailored to individual consumer demands.

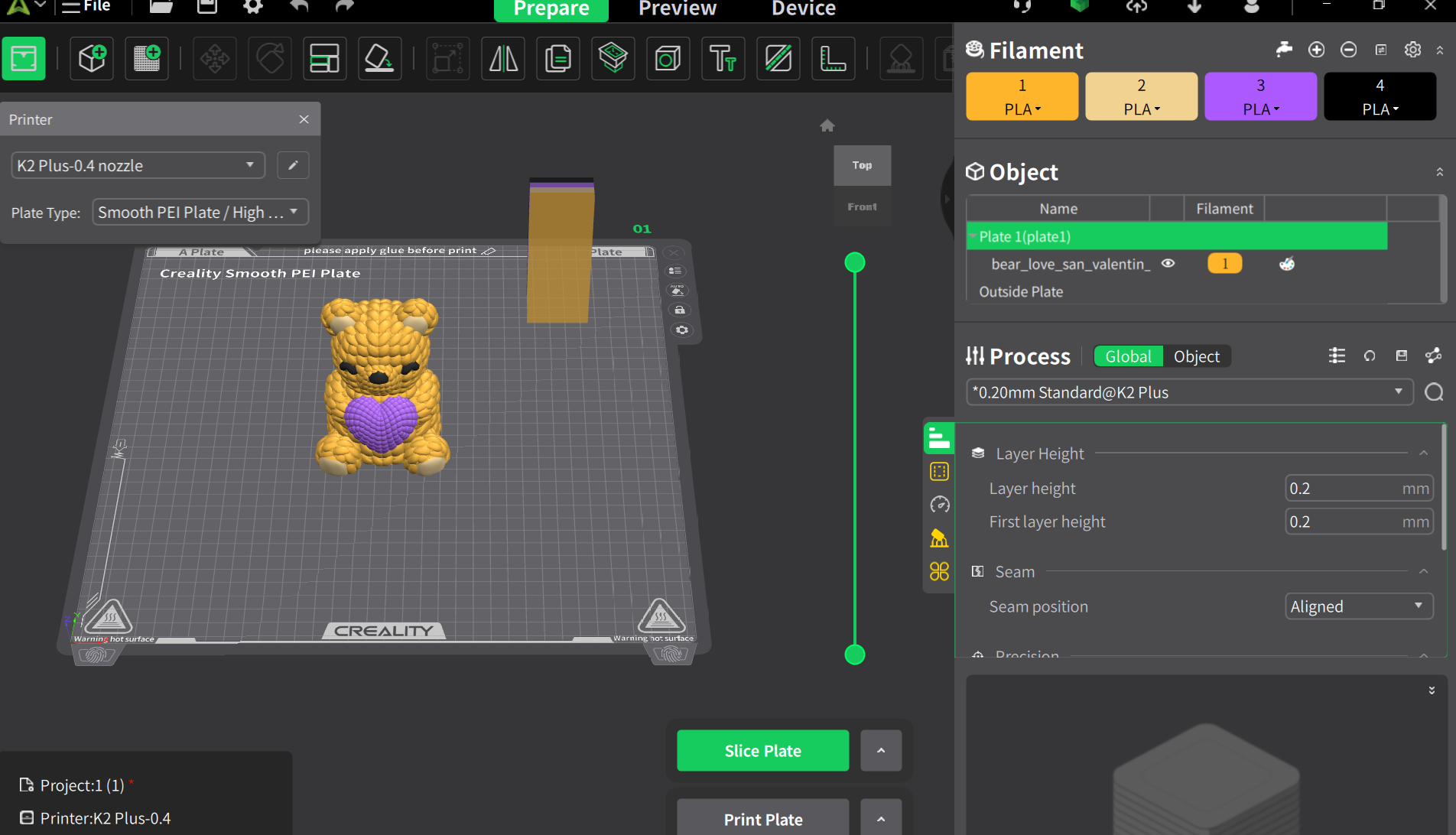

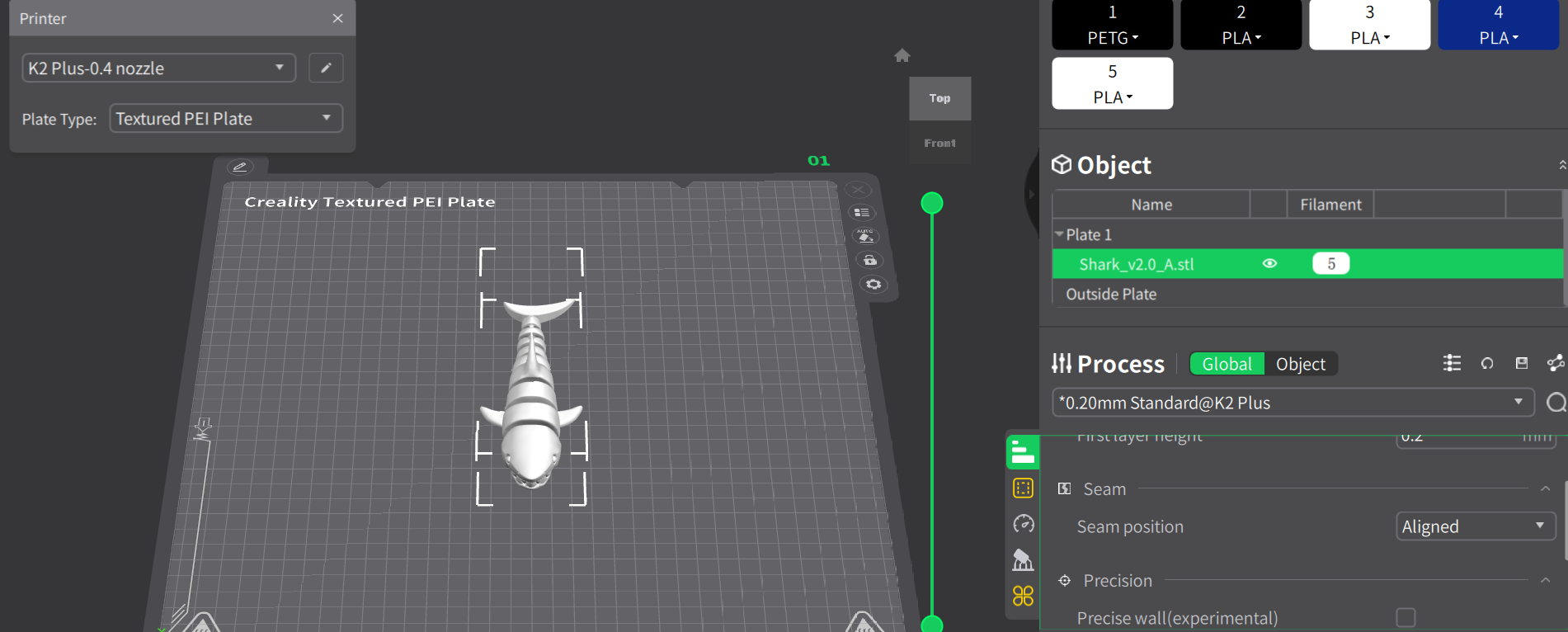

3D printing operators are mainly responsible for operating 3D printers in accordance with production plans and operating specifications. Ensure that printing tasks are completed on time and set printing parameters such as printing speed, temperature, layer thickness, etc. according to requirements.

They can also regularly check and maintain machines, clean and maintain equipment to ensure that 3D printers can operate normally without failure. Printing quality can be monitored in real time.

To be an excellent 3D printing operator, you must be very familiar with common 3D printing technology and understand the principles of printers. Have strong hands-on operation skills, be able to diagnose problems that occur during printing, and have the ability to debug 3D printing equipment. Creality is a leading company in 3D printing. You can learn the operating steps of 3D printing products in Creality, or you can buy our Ender series 3D printers to practice with.

3D printing has a great impact in the automotive industry, construction industry, medical industry, and manufacturing industry.

The impact of 3D printing on future industries

medical industry:3D printing has a profound impact on most industries in the future. In the medical industry, many studies are developing 3D printing technology to print skin, bones, and muscle tissue. This is a tooth printed with ender 3 v3 se.

automotive industry:Cars have been using additive manufacturing technology since their birth. But with the development of 3D printing, many car manufacturers are using 3D printing technology to manufacture car parts. With 3D printing technology, using 3D printers is a practical and low-cost way for engineers to not only prototype their ideas before putting them into more expensive machines, but also design and print usable custom parts.

construction industry:The construction industry is using 3D printing for prototyping and creating complex structures.

manufacturing industry:The manufacturing industry is experiencing a shift towards additive manufacturing, which is changing traditional manufacturing methods.

Skills and Preparation for a Career in 3D Printing

If we want to engage in a career related to 3D printing, we need to have solid skills and more creative ideas than others. We must also excel in business skills.

Technical skills:Proficiency in computer-aided design (CAD) software, 3D modeling, 3D design, and 3D rendering. These skills are needed to create products that are useful to society and can be printed using 3D printers.

Material science knowledge: It is important to understand the properties, limitations and applications of the various consumables used in the 3D printing process. This knowledge can help us choose the right machine and material for the project we need to print, ensuring that our products meet the required specifications.

Business acumen: It’s valuable to understand business models, market trends, and industry growth. Being able to analyze data and make informed decisions can help you navigate the ever-changing 3D printing industry landscape.

Communication and Collaboration: Strong communication and collaboration skills are essential in our work. We need to work effectively with cross-functional teams and ensure that projects proceed smoothly. After all, we cannot do everything by ourselves, and there will always be mistakes. Only in this way can we ensure our common interests.

The Future of Work in 3D Printing

The future of 3D printing jobs will certainly be influenced by a variety of factors, including industry growth, technological advances, and changes in business models. Here are some potential trends and developments:

Understanding 3D printing technology gives recent graduates and most designers a significant advantage in gaining career opportunities in the creative field. This advantage stems from their practical experience and familiarity with the latest 3D methods, making them more competitive in the job market. Learn about the Buying Guide for Creality 3D Printing Materials.

Increased automation: As 3D printing technology advances, there will be more automation in the manufacturing process. While this may lead to job losses in some areas, it also opens up opportunities for positions that focus on overseeing and maintaining automated systems.

New job creation: While 3D printing will displace some jobs, it will also create many new ones. Demand for skilled professionals in fields such as design, engineering, and materials science who can innovate and advance the industry will be high.

Shift to service-based models: As 3D printing becomes more routine, we will see it shift to a service-based business model. Most companies will likely offer 3D printing services rather than selling products, allowing for more customization and on-demand production.

Globalization and remote work: The rise of 3D printing may lead to increased globalization and remote work. Companies can produce products locally and distribute them globally, reducing the need for large-scale manufacturing facilities and enabling more flexible work arrangements.

Skills training and education: To prepare for the future of work in 3D printing, it’s essential to invest in skills training and education. Areas such as CAD design, materials science, and mechanical engineering will be particularly important. Continuous learning and staying updated with the latest technology advances will ensure you remain competitive in the job market.

By understanding these trends and preparing accordingly, you can position yourself for a successful career in the dynamic and evolving field of 3D printing.

Conclusion

If you want to delve deeper into the 3D printing industry, you can start with the most basic understanding of the products. Creality has many 3D printers suitable for beginners, such as our Ender-3 V3. As a novice, you can use it to print the products you want.