The universe of 3D printing has developed fast, bringing a wide range of material choices, particularly for operations that demand heat resistance. Heat-resistant 3D printing material is very popular as it lets engineers create components that can withstand high temperatures. The high-temp 3D printer filament is key in industries such as automotive, aerospace, electronics, and industrial production, where parts must endure thermal strain. Today’s post describes what materials fit as heat-resistant and the way to select the correct one for your job.

What Is a Heat-Resistant 3D Printing Material?

A heat-resistant 3d printer printing material is a type of material that stands up to constant subjection to temperatures more than 100°C in certain scenarios, up to 250°C or more, without compromising its mechanical integrity.

The key properties of these materials include:

-

Thermal resistance: Sustains form at high temperatures

-

Dimensional stability: Maintains precision while post-processing or usage.

-

Chemical resistance: Appropriate for automotive and industrial atmospheres, and great tensile strength that assists with functional and supporting structures.

Mostly, heat-resistant materials are utilized in 3D printing high-temperature parts for challenging jobs. This involves housing close-by engines, brackets in aircraft, or parts in electronics, where heat transfer is crucial.

As stated in a study published in Polymers (MDPI, 2022), 3d printer printing materials such as PEI and PEEK provide heat distortion temperatures (HDT) over 200°C, making them perfect for automotive and aerospace requirements.

Such high temperature 3D printing materials are unlike primary alternatives such as PLA or standard ABS, which weaken or deform at lower temperatures.

Top High-Temp 3D Printing Filaments

Picking out the correct high temperature 3D printing materials is key when creating parts vulnerable to pressure, heat, or demanding working settings. Every material possesses particular strength, heat resistance, and compatibility criteria. Below are the high temp 3d printer filaments:

-

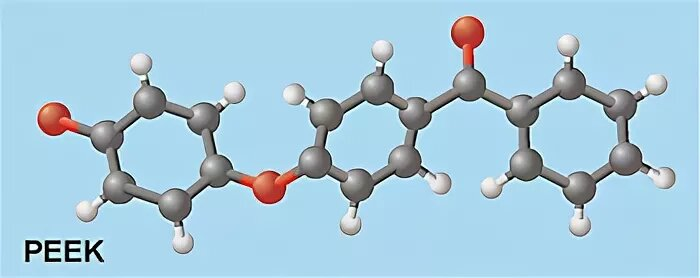

PEEK (Polyether Ether Ketone)

PEEK composite, or PEEK, is among the most innovative high temp 3D printer filament choices at hand today. It provides the greatest heat resistance for FDM 3D printing, with a heat resistance of up to 250°C for constant usage.

This makes it qualified for popular applications in automotive, aerospace, and medical spheres. PEEK is recognized for its exceptional chemical resistance, tensile strength, and long-lasting stability.

-

Pros: Incredibly great heat resistance, outstanding strength, chemical resistance, and long-standing durability.

-

Cons: Costly, needs a special 3D printer printing material setting with an encased build chamber, and an extruder capable of 350–400°C, cannot melt and extrude easily, so lower consistency and soundness.

PEI (ULTEM)

ULTM, another title for polyetherimide (PEI), is a commercial-grade, efficient, thermoplastic heat-resistant 3D printing material utilized in FDM 3d printing and in supervised industries such as healthcare and aerospace.

Having an HDT of around 210°C and a great mechanical strength, PEI brings the right balance between printability and performance relative to PEEK. This makes it famous for building elements where trustworthiness is necessary.

-

Pros: Powerful heat resistance, naturally nonflammable, appropriate for sterile and controlled settings.

-

Cons: Still demands a high-temperature printer setting; not as adaptable as other materials.

Polycarbonate (PC)

Polycarbonate is a high-performance thermoplastic that is appreciated for its heat resistance (110°C to 150°C), and toughness. This transparent material works well under mechanical stress, so perfect for housings, light covers, and high tensile functional prototypes.

PC high temp 3d printer filament is commonly used in professional 3D printing high temperature uses that do not need the industrial range of PEI or PEEK. Besides, it’s used in FDM and SLA 3D printing and can transfer above 90% light, as transparent as glass, and is practically shatterproof.

-

Pros: Impact resistance, Powerful, and optically transparent; best for challenging prototypes.

-

Cons: Demands an enclosed printer; exposed to deformation; high moisture absorption.

Nylon (with Glass or Carbon Fiber Fill)

Nylon mixtures, specifically the ones strengthened with carbon fiber or glass, provide superb tensile strength and medium heat resistance of up to 120°C. The 3d printer printing material is featherlight and shock-resistant; therefore, best for uses where rigidness and thermal balance are key, like bushings, strong end-use components, gears, and brackets that need toughness and flexibility.

-

Pros: Adaptable, strong, and long-lasting; carbo/glass-filled variants improve heat and strength characteristics.

-

Cons: Can soak up dampness fast; needs dry storage and pre-print drying up for ideal outcomes.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a frequently utilized thermoplastic that can withstand temperatures up to around 100°C. This heat resistant 3d printing material stays among the most budget-friendly alternatives for 3D printing material requirements that involve modest heat resistance. ABS is widely used in mechanical housings, inclusions, and other functional elements.

PETG (Modified Variants)

PETG offers a happy medium between ABS and PLA. Modified PETG provides a little bit superior heat resistance (generally around 80°C–90°C) and effortless printing. Additionally, it is chemical-proof and generates less bending.

This makes it a famous option for common applications such as electrical coverings and mechanical covers.

What Material Does a 3D Printer Use for Heat Resistance?

Resin-based and Fused Deposition Modeling (FDM) setups utilize separate materials for heat resistance. Typically, FDM printers use filaments like PC, PEEK, and ABS; however, resin printers utilize heat-resistant photopolymers.

Below is the table outlining material comparison by usage scenario:

|

Material

|

Max Temp (°C)

|

Type

|

Usage scenario

|

| PEEK | 250+ | FDM |

Aerospace, automotive

|

| PEI/ULTEM | 210 | FDM |

Medical, industrial

|

| PC | 150 | FDM |

Mechanical parts

|

| ABS | 100 | FDM |

Enclosures, functional parts

|

| PETG | 90 | FDM |

General purpose

|

| Heat-Resin | ~200 | FDM |

Molds, precision parts

|

Factors to Consider

To choose the best material, consider these factors:

-

What material does a 3d printer use? This relies on the frame of machine temperature range, the kind of extruder, and the chamber design.

-

Temperature and Material Toughness: Select materials that balance mechanical strength and heat resistance for your usage.

-

Cost vs. Function: Efficient materials are expensive; they have lower breakdowns and upkeep in high-heat usage.

Choosing the right heat-resistant 3D printing material guarantees good prints that survive in extreme heat. So, always suit the material’s temperature limit to your part’s physical environment.

What Makes a 3D Printer Capable of High-Temperature Printing?

Not every printer approves of 3D printing high-temperature filaments. A printer has to reach exacting hardware standards to manage industrial-grade materials.

Nozzle Temperature Range

Performant filaments need hot ends that can get to 250°C to 450°C. For instance: ABS and PC up to 240°C–280°C and PEEK and PEI up to 350°C–400°C. A high-temp 3D printer filament system must utilize temperature sensors and a full metal hotend assessed for prolonged exposure.

Heated Bed

The key to bed adhesion and bend avoidance is a hot print bed, and the perfect bed temperature differs:

-

PC: 100°C to 120°C

-

PEEK/PEI: 120°C–160°C

-

ABS: 90°C–110°C

Enclosed Build Chamber

Enclosures sustain constant room temperature, and that is crucial for materials that chip off or shrink when chilled too fast. Considering PEI or PEEK, a 70°C–90°C chamber temperature assists in confirming layer adhesion.

Material Compatibility

Printers ought to have hardware corresponding to coarse and chemical-resistant materials. For instance, PEEK demands rugged nozzles (e.g., hardened steel or ruby-tipped) to manage filament toughness.

Creality offers the Creality K1 Max, which assists with high-temp 3D printer filament with a 300°C hotend, a hot bed up to 100°C, elective enclosure. This 3D printer is appropriate for professional-grade materials such as PC and strengthened Nylon, and its features allow people to print long-lasting components with precision.

Common Applications of High-Temperature 3D Printing

The heat-resistant 3D printing material is used in several sectors:

|

Industry

|

Application Example

|

|

Aerospace

|

Interior mounts, ducts, and tool holders

|

|

Automative

|

Under-hood elements, brackets

|

|

Electronics

|

Insulating housings, PCB supports

|

|

Manufacturing

|

Molds, jigs, fixtures

|

|

Medical

|

Sterilizable tools, tailor-made implants

|

How Creality Supports High-Temp 3D Printing Projects?

Creality brings equipment and resources for 3D printing high-temperature materials. 3D printers such as the K1 Max and Ender-3 S1 Pro present, PEI 3D printer bed, 300°C nozzles, and direct drive extruders. This makes them perfect for high temp filaments such as nylon and PC. Moreover, Creality helps both its personal and third-party heat-resistant 3D printing materials, in the company of cloud models, user guides, and community forums accessible for assistance.

Tips for Printing High-Temperature Materials

To print 3D printing materials successfully demands close attention to the atmosphere and settings. Stick to the following tips:

-

Manage atmospheric temperature: Utilize an enclosure to avoid bending and parting the layer.

-

Use the right bed bonding: Glue sticks or PEI sheets enhance bonding for materials such as PC and ABS.

-

Calibrate attentively: Adjust nozzle height, retraction, and cooling setups for ideal outcomes.

-

Ventilate the work area: Filaments such as nylon and ABS might discharge fumes.

-

Dry out the filament: Humidity-sensitive filaments (e.g., nylon) require drying before usage.

Conclusion

While industries such as automotive production and aerospace engineering expand the adoption of 3D printing technology, heat-resistant 3D printing materials are progressively in great demand. So, selecting the correct material for 3D printing rests on the particular needs of your usage, involving mechanical strain, temperature subjection, and environmental conditions. That said, if you’re new to 3D printing and confused about 3D printing materials, you’ll find everything you need on Creality Wiki.