In Japan, a new generation of engineers is taking its first steps toward Mars. ARES Project, led by students from Tohoku University and Keio University, is Japan’s first student-driven Mars rover development team to participate in the University Rover Challenge (URC) in the United States. Their mission goes beyond competition to build real-world capabilities in robotics, aerospace, and advanced manufacturing while inspiring future student innovators to grow the field.

Student Teams Learning Through Research and Innovation

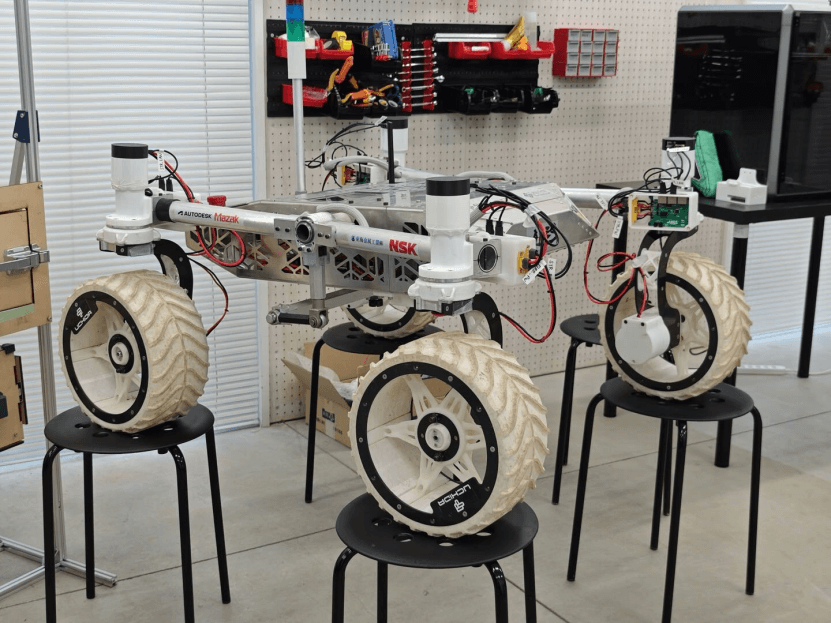

The ARES Project brings together more than 40 students from universities across Japan to design, build, and operate a fully functional Mars rover. Through this hands-on collaboration, students gain practical experience that bridges classroom theory with real-world aerospace engineering, from CAD design and mechanical assembly to sensor integration and field testing.

To meet the complex demands of the University Rover Challenge (URC) and other international competitions, the team is organised into three main divisions: rover development, robotic arm, and control and science modules. Each division works closely together to achieve precise mobility, reliable manipulation, and autonomous operation under the harsh conditions simulated by the competition.

Managing these interconnected systems and meeting diverse technical requirements is one of ARES’s greatest challenges, and also its strongest educational value. Through this process, students learn to collaborate, problem-solve, and innovate like real engineers in space exploration.

3D Printing at the Core of Discovery

From the beginning, the team’s engineering approach has been powered by Creality 3D printers. Every prototype, from early concept models to competition-ready rovers, has relied on parts fabricated using Creality machines.

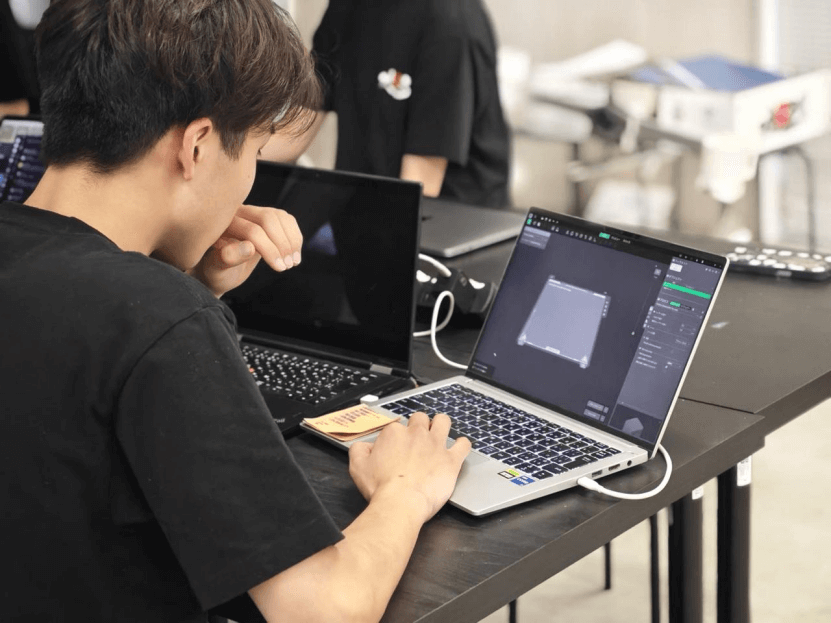

With 3D printing, ARES can design, print, and test new components in days rather than weeks. This rapid iteration cycle allows them to refine structural and mechanical performance while keeping costs low — a crucial advantage for a student team.

Components such as robotic arm grippers, electronic housings, board mounts, and flexible TPU wheels are all printed in-house using Creality’s precision 3D-printing technology, enabling the team to create complex geometries that would be difficult or impossible to achieve through traditional machining, including lightweight lattice structures, multi-jointed grippers, and elastic wheel patterns optimised for uneven terrain.

As the team explains, “3D printing has fundamentally transformed our development process by enabling rapid, cost-effective and flexible fabrication of rover components.”

Engineering Flexibility with Creality Tools

ARES primarily uses PLA for early-stage prototyping and ABS for heat-resistant final parts, while TPU is employed for custom, full-scale rover tyres, each optimised for traction and durability. This combination enables high-performance structures with lightweight efficiency, meeting the strict weight requirements of the URC.

Creality’s Ender Series printers serve as everyday workhorses in both student labs and personal study spaces. Many new members begin learning 3D printing with their own Ender-3 units, gaining design-for-manufacturing skills early in their education. During competitions, the team often brings compact Ender Series printers to the field to reprint spare components on-site, a crucial advantage for real-time problem-solving.

For larger parts, the K Series printers provide expanded build capacity and precision, allowing the production of full-size rover frames and oversized TPU wheels. Its speed and reliability have made it an essential tool in preparing for international contests.

Bridging Regions, Building the Future

Through Creality’s technology, ARES has turned regional distance into an advantage. Students can now design in one city and print in another, creating a unified, distributed workshop environment. This model not only improves efficiency but also mirrors how global engineering teams collaborate on real aerospace projects.

The project also demonstrates the growing educational potential of 3D printing. By giving students the freedom to design, test, and refine real components, Creality technology is helping practical problem-solvers to tackle the challenges of future space missions.

Toward 2026 and Beyond

Following their participation in the 2024 URC, the ARES team is aiming higher than ever — targeting a top finish in 2026. To reach that goal, they plan to integrate metal 3D printing and hybrid fabrication, combining printed polymers with carbon-fibre or metallic components for enhanced durability.

For Creality, this collaboration demonstrates how accessible, reliable, and educational 3D printing tools can empower the next generation of innovators. The ARES Project embodies the spirit of exploration and creativity that defines the Creality community: using technology not just to build machines, but to offer the tools to shape the future of human discovery.

Watch the video to learn about how the ARES team has made a rover with 3D printers.