Shoe insole support drastically improves foot comfort and reduces back pain. Numerous studies have shown that something as simple as a single insert can improve gait, increase walking range of motion, and alleviate the pressure of flat feet.

As the population ages and more people engage in outdoor activities, ranging from birdwatching to basketball, the demand for custom inserts is on the rise. The problem is that traditional orthotic devices require foam casting, plaster molding, and CNC milling, which consume a significant amount of time and resources.

3D printing in orthotics is transforming the market. It brings much-needed pain relief to a broader client base due to faster turnaround times, solving imperfect fits, and lowering the cost of product development. With the right equipment, a lab or private supplier can offer 3D printed supports designed specifically for a single user instead of a “fits most” solution.

What Exactly are Custom 3D Printed Orthotics?

The concept of 3D printed orthotics is straightforward. A 3D printer uses custom scans and modeling to generate supportive orthotics insoles (or similar structures) with layer upon layer of polymers like TPU, nylon, or resin.

The primary difference between 3D printed custom orthotics and traditional support is that the older style relies on prefabricated molds that must be manually carved. These are popular brands, such as Dr. Scholl’s, Redi-Thotics, or Nazaroo, which can be found in most pharmacies or specialty shoe stores.

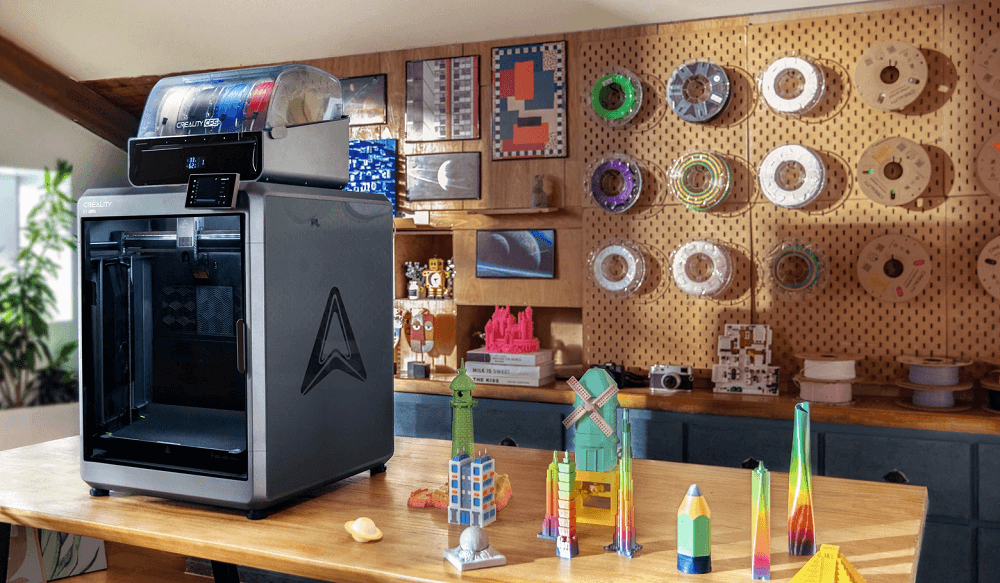

Not every person seeking support can use a one-size-fits-all insert. With an efficient and versatile printer from Creality, personalization of each orthotic is possible. Foot scans and CAD software enable a greater emphasis on functional design, addressing plantar fasciitis, flat feet, diabetic foot ulcers, or providing shoes with added comfort for everyday movement.

The Many Benefits of 3D Printed Orthotics

Considering that around 1 in 10 people suffer from plantar fasciitis (not to mention other foot issues), having 3D printed custom orthotics is a massive benefit to comfort and pain relief. Other benefits include:

Customization & Perfect Fit

A basic insole won’t address the needs of a singular user. Using technology like digital pressure mapping and 3D scanning to analyze a patient's biomechanics allows practitioners and amateurs to better assess pronation, supination, arch height, and load distribution. The resulting 3D printed insole matches the individual’s foot anatomy and gait.

Lightweight & Durable

Modern 3D printed shoe insoles can be made using lighter-weight materials offering just as much, if not more, durability over traditional solutions. TPU provides a high level of flexibility, especially when reinforced with nylon, compared to conventional EVA foam or rigid plastic. The K2 Plus is an excellent example of a TPU printer perfect for such insole construction.

Faster Turnaround & Design

Whenever a customized orthotic needs to be created, patients often expect a 2 to 4 week turnaround time. 3D printing with additive materials reduces this timeframe to 1 to 3 days, often including any rapid prototyping or adjustment. That means a patient can have their feet scanned on a Monday and receive new insoles on a Wednesday for adjustment.

Lower Waste & Upfront Operating Cost

Most 3D printers on the market can reduce waste in orthotic creation. Instead of overcutting or leftover molds and foam, the filament is precisely utilized. Additionally, sourcing a 3D printer from Creality incurs a lower upfront cost compared to setting up a complete manufacturing facility for traditional molds with manual shaping.

Where are 3D Printed Orthotics Commonly Used?

3D printed supports are not regulated to group facilities for aging citizens. Many users can benefit from the support and comfort that such solutions offer.

Sports Orthotics

The NBA has gotten into the orthotics game, relying on real-time biometric scanning for individualized support creation. 3D printed solutions help control stiffness, rebound, and load distribution. This can enhance performance in soccer, running, basketball, and more, as well as lower the potential for injuries due to greater control. Having a high-resolution printer like the K1 Max enables performance-driven orthotics for various sports applications.

Diabetic & Medical Footwear

Around 11.6% of the U.S. population (38.4 million) has diabetes. Having 3D printed shoe insoles helps offload pressure to prevent ulceration in the feet. Traditional insoles cannot match that level of individual support, as scanning identifies pressure zones, allowing for the creation of specific, variable-density lattice structures.

Daily Wear & Comfort for Aging Users

Sports and medical issues are one thing, but everyone will age. The foot is an amazing appendage in that minor issues, such as collapsing arches and uneven gait, become much more significant as one gets older. 3D printed orthotics help correct alignment and reduce joint stress. It restores balance, allowing anyone of any age to enjoy a walk in the park without pain or discomfort.

Professional Benchmark: PhITS Orthotics

A good example of how 3D printing technology can revolutionize the industry is the PhITS 3D printed orthotics line. These are custom-made, corrective insoles that utilize dynamic gait analysis and active scanning with SLS printing to produce premium-level insoles. The beauty is that PhITS operates at scale, meaning smaller labs can mirror the same approach using modular equipment like the HALOT-MAGE Pro to create comparable solutions on a smaller budget.

What are the Best Materials to Use with 3D Printing Orthotics?

Material choice is a crucial decision in 3D printed orthotics. No one wants to purchase an item that won’t hold up to sports, medical, or daily use. The three most common options include:

-

Flexible TPU with excellent rebound and cushion for longer walks and sports applications.

-

Durable Nylon (PA12) to add more strength for postural correction if the patient needs midfoot stability.

-

Photopolymer resins (SLA/DLP) provide a more rigid structure for support when braces or shells are required.

Creality printers can work with all three material types, ensuring a versatile solution at a fraction of the cost of traditional manufacturing or manual labor. That way, individualized orthotics can be generated based on the unique patient.

What is the Secret Sauce for Designing 3D Print Custom Orthotics?

When there is a way to generate 3D printed shoe insoles without all the extra equipment or staff, it allows greater personalization of the solution. However, everyone from a small clinic to a specialty shoe store needs a system for designing, adapting, and finalizing each orthotic. That could include:

-

Capturing foot data through active gait scanning and pressure analysis (smart insoles, gait tracking apps, pressure plate systems, etc.).

-

Implementing CAD-based design software like Blender, Fusion 360, or TinkerCAD to address heel cup depth, arch support, rearfoot control, lattice infill zones, and more.

-

Using Creality Print to slice the design for optimal infill density, layer height, supports, and matching temperature settings to the material.

-

Printing the 3D printed supports using advanced and versatile equipment like Creality, mixed with resins, dual extruder setups, or FDM solutions.

The final step cannot be overlooked. Special attention needs to be taken to post-processing and fit testing. All supports need to be carefully removed, and the resin must be cured so that fit testing with the patient results in a supportive and comfortable fit.

Why Choose Creality for Orthopedic 3D Printing

Creality has a hardware ecosystem perfect for custom orthotics, prosthetics devices, orthotics insoles, and medical modeling. The affordable, high-precision 3D printers range from smaller, in-house solutions to full-scale machines perfect for clinics and commercial shoe stores. These 3D printers are compatible with TPU, nylon, and resin, ensuring a strong lattice structure that holds up to sports use or someone in need of support while walking the dog.

Explore Creality’s medical-grade 3D printing solutions and ensure patients have a comfortable fit for addressing chronic pain or simply feeling more supported while riding a bike.

The Future of Orthotic Comfort Starts with 3D Printing

3D printed orthotics are a wonderful way to ensure a patient has personalized support needed for a wide range of medical issues. They offer comfortable solutions with lower upfront costs and reduced waste compared to traditional insole manufacturing.

Drop the one-size-fits-all solutions and move to a more precision-crafted orthotic solution that is lighter, faster, and more effective, utilizing 3D printed technology. With the right combination of scanning, CAD modeling, and Creality equipment, the future of individual orthotic care is brighter and better than ever.

FAQs

What are most 3D printed orthotics made from?

The materials most commonly used in 3D printed orthotics are TPU, nylon, and resin. These help with flexible cushioning, durability, and rigid structural elements depending on the individual patient’s needs.

Are 3D printed insoles better than traditional ones?

Yes. Not only are 3D printed solutions easier to source, taking less time and resources, but they also better adapt to a singular person instead of an off-the-shelf item that “fits most.”

Can I print custom shoe insoles at home?

Yes, but you’ll want to have a decent 3D scanner or foot gait analysis application. Be sure to use CAD-related software for design and Creality’s software for slicing to ensure the outcome is 100% adapted to your specific foot support needs.

Which 3D printers are best for printing orthotics?

The ideal printers are those capable of using flexible filaments like TPU with a direct drive extruder and consistent bed adhesion. You’ll find many of those devices throughout Creality’s inventory.