As printers become cheaper and more user-friendly, tens of thousands of users worldwide are now running 3D print jobs in bedrooms, classrooms, garages, and labs.

But as access expands, so does concern over a previously underestimated risk: fume emissions from filament materials. While early enthusiasts often focused on print quality, strength, or speed, the conversation in 2025 has matured. Health and environmental safety are now core concerns, especially in confined or shared spaces.

The two most commonly used filaments, PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene), present starkly different safety profiles. Understanding these differences isn’t just about choosing the right filament for a project. It's about protecting your lungs, your children, and your workspace.

This post explores the evolving discussion around ABS vs PLA printing safety 2025.

What Is the Difference Between PLA and ABS Filament?

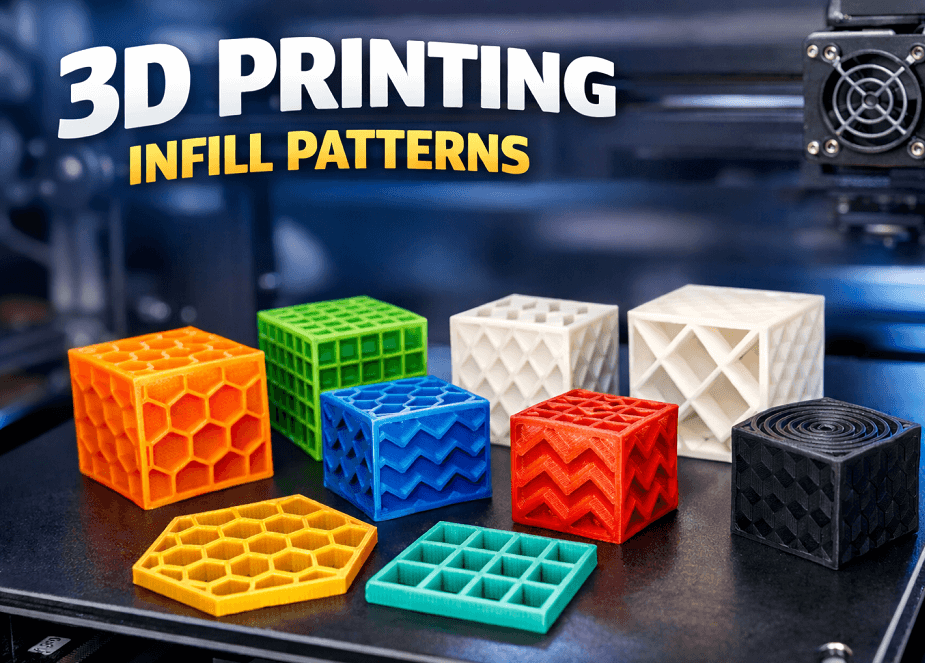

PLA and ABS are the backbone of filament-based 3D printing. They may look similar as spools on a shelf, but their origins, print behavior, and emissions couldn’t be more different. So, what is the difference between PLA and ABS filament?

PLA: The Plant-Based Pioneer

-

Origin: Made from renewable plant starches like corn and sugarcane.

-

Print Temp: 180–220°C

-

Strength: Moderate tensile strength; brittle under impact.

-

Smell: Sweet, faint candy-like odor.

-

Safety Profile: Low emissions of VOCs and ultrafine particles.

-

Biodegradable: Under industrial composting conditions.

PLA is the filament of choice for educational institutions and homes largely due to its ease of use and lower toxicity profile.

ABS: The Industrial Workhorse with a Dark Side

-

Origin: Petroleum-derived thermoplastic polymer.

-

Print Temp: 220–260°C

-

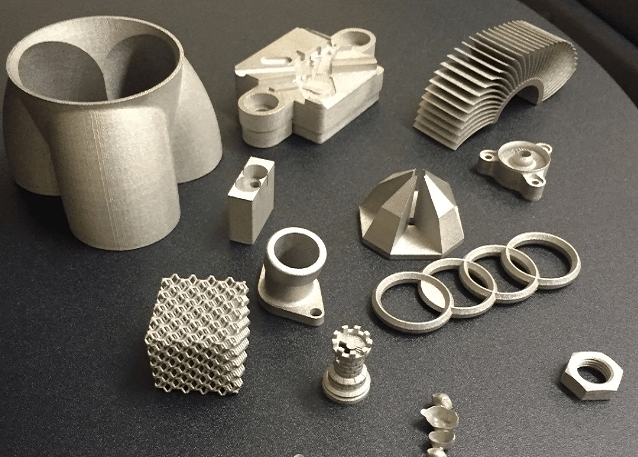

Strength: Higher durability and impact resistance than PLA.

-

Smell: Strong, plastic-like, often irritating.

-

Safety Profile: Emits large volumes of styrene.

-

Environmental Hazard: Not biodegradable.

ABS’s strength and heat resistance make it popular in demanding applications, but it’s associated with high levels of VOCs like styrene and formaldehyde.

Is ABS Stronger Than PLA?

ABS is generally stronger than PLA, especially in applications that require impact resistance, flexibility under stress, and thermal endurance.

Tensile Strength and Flexibility

-

PLA: It has a higher raw tensile strength (60 MPa) than ABS (40 MPa), which can be misleading if viewed in isolation. PLA is stiff and brittle, meaning it snaps rather than bends.

-

ABS: Though it has lower tensile strength, it's much more impact-resistant and ductile, allowing it to absorb shocks and flex under strain without cracking.

Heat Resistance

-

PLA softens at around 60°C (glass transition point).

-

ABS handles up to 100°C, making it a better choice for automotive parts, machine enclosures, or anything exposed to warm environments.

Durability and Post-processing

-

PLA can warp or degrade in humid conditions.

-

ABS is more chemically stable, solvent-resistant, and allows for acetone vapor smoothing, making it a favorite in prototyping for professional applications.

When to Choose ABS Over PLA

-

You need a part to handle high mechanical stress or impact (e.g., gear housings, enclosures, machine parts).

-

The print will be exposed to moderate-to-high temperatures.

-

You plan to post-process with sanding or smoothing solvents.

-

You’re printing in a well-ventilated, controlled workshop, not a living space or classroom.

How Much Fumes Does ABS Give Off Compared to PLA?

The difference in emissions between ABS and PLA is drastic.

ABS Fumes: A Toxic Tradeoff

ABS releases large amounts of styrene, a volatile organic compound (VOC) classified by the International Agency for Research on Cancer (IARC) as “possibly carcinogenic to humans” (Group 2B).

Styrene exposure has been associated with:

-

Eye, nose, and throat irritation

-

Headaches and fatigue

-

Long-term risks to the nervous system and liver

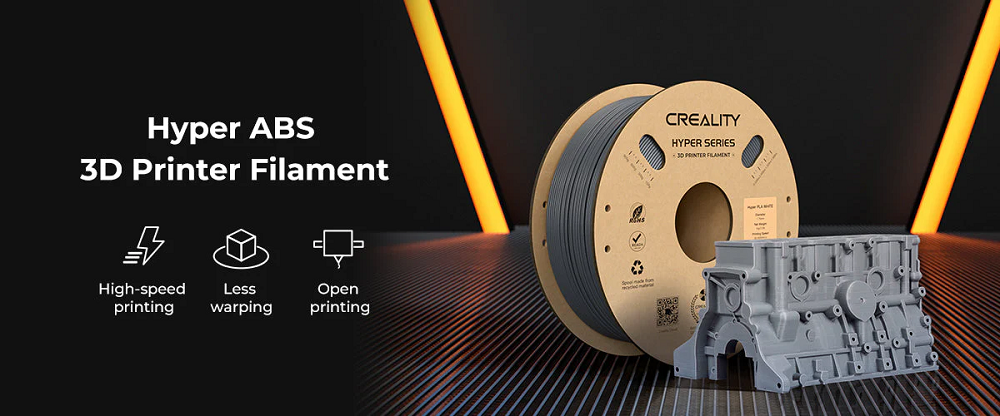

In some print environments, formaldehyde and benzene were also detected as byproducts from ABS-based materials. Even Creality recommends minimizing ABS use without proper air handling.

PLA Emissions: Low-Risk, but Not Zero

PLA is widely regarded as the safer alternative. Emissions are largely made up of:

-

Lactide (a mild organic compound)

-

Trace VOCs at levels considered safe in typical ventilation scenarios

PLA emissions are well below occupational exposure limits unless the printer is enclosed in a completely sealed, unventilated area.

However, caution is still warranted with:

-

PLA blends that contain additives (metallics, glow-in-the-dark agents)

-

Poorly ventilated rooms, especially over long print durations

Is ABS Material Dangerous to Print in 2025?

ABS (Acrylonitrile Butadiene Styrene) has long been a staple of 3D printing, prized for its strength, flexibility, and heat resistance. However, with the increased awareness of health and safety risks associated with its toxic fumes, particularly styrene, users are beginning to rethink its place in home and educational environments. Many can’t help but wonder, is ABS material dangerous? Is ABS toxic to print?

Updated Health Research in 2025

In 2025, research on 3D printing emissions has become more robust, with scientific studies from ResearchGate confirming the dangers of styrene exposure.

Key Findings:

-

Styrene is a known irritant and a possible human carcinogen. Short-term exposure can lead to headaches, nausea, and respiratory issues, while long-term exposure may affect the liver, kidney, and nervous system.

-

UL and OSHA guidelines now recommend that all ABS printing environments have ventilation systems in place, including HEPA and carbon filtration.

-

A 2024 study suggests that excessive styrene exposure from prolonged ABS printing in poorly ventilated spaces can cause lasting damage to respiratory health, particularly for young children, sensitive individuals, and pets.

These findings underscore why printing ABS without proper ventilation is dangerous. Unfiltered fumes in enclosed spaces increase the risk of health issues for those exposed. As of 2025, the general recommendation is to avoid printing ABS in home environments unless enclosed printers with active ventilation systems are used.

Risks of Printing ABS Without Proper Ventilation

-

Health Risks: Direct exposure to styrene is particularly concerning, especially in confined spaces. Poor air circulation allows the styrene levels to accumulate in the air, leading to potential respiratory distress, irritation of eyes and throat, and fatigue. Long-term exposure has been linked to chronic neurological problems and cancer risk.

-

Environmental Impact: Without proper filtration, the emissions from ABS can contribute to indoor air pollution and the spread of fine particulate matter (UFPs). This is concerning not only from a health standpoint but also for air quality in non-industrial spaces.

New Developments in Safer ABS Variants

The 3D printing landscape has seen a rise in lower-emission ABS alternatives. These newer variants are designed to reduce harmful emissions, making them safer for home and educational use. Some brands now offer ABS+ or Eco-ABS formulations that:

-

Emit fewer VOCs and styrene.

-

Offer improved printing characteristics like lower odor and reduced warping.

-

Are marketed as "healthier alternatives" with enhanced safety features.

However, it’s important to note that no ABS filament is entirely free of risks when it comes to fume emissions.

Best ABS 3D Printer Filament Recommendations

When selecting an ABS filament in 2025, it’s crucial to prioritize safety alongside performance. Here are some of the top-rated, safer ABS filament options available today:

Creality Hyper ABS – The High-Speed Standard for Modern Makers: As high-speed 3D printing becomes the norm in 2025, Creality’s Hyper ABS stands out by balancing extreme performance with improved user safety. Specifically engineered for high-flow printers like the K2 series, it solves two of the biggest hurdles of traditional ABS: slow print speeds and overpowering fumes.

Key Considerations When Choosing ABS Filament for Safety:

-

Low Odor: Filaments like Hyper ABS are known for their lower odor profiles, making them more tolerable for home use.

-

Reputable Brands: Choose brands that have ABS variants designed for lower emissions. Look for certifications or customer reviews that mention filament safety.

-

High Performance: Even with safety measures, your filament should still perform well under stress. As such, opt for filaments that balance safety, strength, and print quality.

PLA Printing Safety: Still the Best for Beginners?

Even with an ever-growing list of filament options, PLA remains the safest and most accessible choice for beginner and everyday users.

Why PLA Still Reigns in Entry-Level Safety

-

Low Emissions: PLA releases negligible amounts of VOCs and ultrafine particles (UFPs) under normal print conditions.

-

Plant-Based & Biodegradable: PLA is made from renewable starches and is industrially compostable, making it safer not only for your lungs but also for the environment.

-

No Heated Enclosure Needed: Unlike ABS, PLA doesn’t require a high-temperature print chamber, making it ideal for open-frame printers in bedrooms, living rooms, or classrooms.

Safe PLA Printing Practices

-

Ventilation is still recommended, especially during long prints.

-

Avoid exotic PLA blends (e.g., metallic or glow-in-the-dark) unless you understand their additive profile.

-

Keep children and pets away during and immediately after printing, as heated components and residual fumes may still pose minor risks.

Final Thoughts: Choosing the Right Filament for Safe 3D Printing

Whether you're a weekend maker or a full-time prototyper, your filament choice directly affects both project quality and personal safety. Here’s a practical recap:

PLA: Safe, Sustainable, Simple

-

Minimal emissions

-

Safe for indoor use with basic ventilation

-

Ideal for visual models, prototypes, and educational prints

ABS: Strong but Risky

-

High durability, but emits toxic VOCs (especially styrene)

-

Requires enclosure, HEPA + carbon filtration, or external ventilation

-

Should not be used in enclosed or shared living spaces without protective measures

Best Practices for ABS Users

-

Use enclosed printers with active carbon and HEPA filtration

-

Print in a dedicated, ventilated workshop

-

Wear a respirator mask (rated for VOCs) if working near the printer for extended periods

-

Avoid prolonged use around children, elderly people, or pets

The truth is, there’s no one-size-fits-all answer in the ABS vs PLA printing safety 2025 debate. If safety matters to you, always ensure you have adequate ventilation and use enclosed printers where recommended.

FAQs On 3D Printing Safety

Is PLA completely safe to print?

PLA is among the safest filaments, especially in well-ventilated spaces. However, some blends may contain additives that release more fumes, so always check the datasheet.

What filters are best for ABS printing fumes?

Use HEPA + activated carbon filters to capture both ultrafine particles and VOCs like styrene. Brands that advertise lab-tested filter ratings are preferred.

Does ABS smell bad when printed?

Yes. ABS typically gives off a strong, plastic-like odor due to styrene. If it smells harsh or causes irritation, you're likely not using proper filtration or ventilation.

What’s Your Safe Printing Setup?

We’ve shared the facts, now we want to hear from you!

-

What precautions do you take when printing ABS?

-

Have you experimented with low-emission ABS filaments?

-

Are you a PLA loyalist or have you found a safe way to print tougher materials?