Are you struggling with ABS print speeds? If you print too fast, warping becomes an issue; too slow, and you waste valuable time. Let's find the sweet spot! Unfortunately, most people buying 3D printers often use them with their default settings. They have no idea how much control they have regarding tinkering with the original settings.

For those that have made any changes, as you may have already noticed, print speeds determine many things, including print quality, smoothness, and overall outlook. You want a speed that is fast enough possible without compromising on quality. Remember, you may want to print quickly only to end up with an unusable print, which will be a waste of time, filament, and energy.

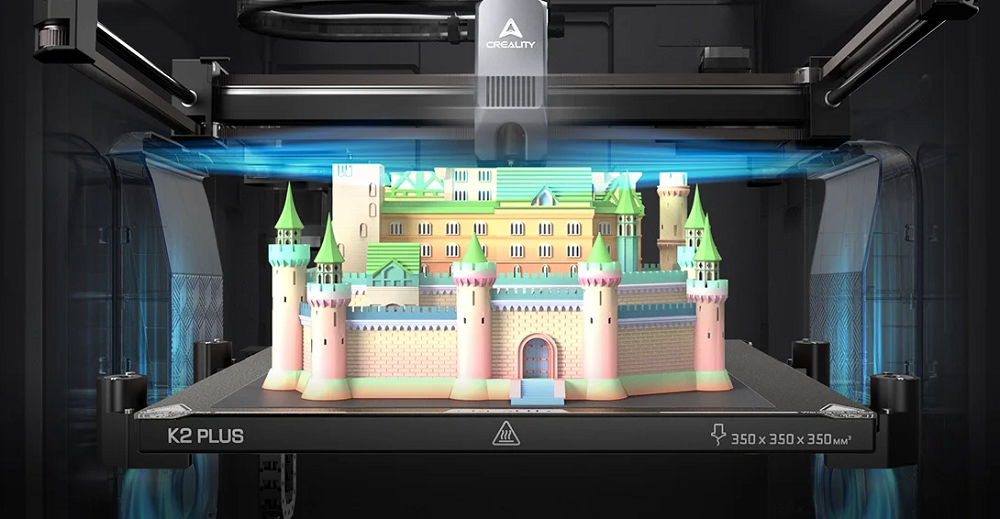

Fortunately, you have the flexibility to fine-tune ABS print speeds to achieve optimal results. When choosing a 3D printer, having a strong community and plenty of customization options is crucial—especially if you want to tweak settings and enhance performance. Creality stands out as your ultimate resource for mastering ABS printing, particularly with models like the K2 Plus or Ender series; with their highly customizable printing environment, you can easily tailor settings to suit your specific needs.

Why ABS Print Speed Matters

There are three things that you want to stay on top of when printing ABS: the first layer adhesion, structural integrity of the build, and surface quality of the final product.

ABS stands for Acrylonitrile Butadiene Styrene. Technically, these are constituent types of plastics that make up ABS filaments. The filaments require careful speed control due to their thermal properties. First, ABS requires higher printing temperatures. What does that mean? It means that the filament takes longer to cool, which can affect how subsequent layers interact with the previous layer. As you can see, there is bound to be a problem if you are printing too slowly or too fast.

When it comes to layer adhesion, ABS print speeds can significantly determine how each layer adheres to the beds. Let's look at ABS qualities and what potentially happens during printing. Since ABS takes longer to cool than PLA and PETG, speed affects two things. First, the layers take longer to adhere to the surface or subsequent layers. Secondly, at high speeds, the layers are prone to printer vibrations, which tend to increase with the increase in printing speed.

So, pouring more filament means higher heating requirements even higher cooling requirements, and faster extruders or a direct drive extrusion. And that is why printers have a low print speed for ABS 3d printer filament when compared to PLA or PETG. That means that the amount of filament printed, typically around 40-60mm/s, adheres better. It cools uniformly without affecting subsequent layers, reducing warping. Keeping the layers uniformly formed improves the quality of the finished surface.

On the other hand, PLA requires less printing temperature and cools much faster. A trick that has worked to increase print speed while minimizing warping is changing the slicer settings to print the inner layers first and then the outer layers.

ABS Print Speed Limits

Typical Range

Even for faster brands, 30-60 mm/s is the baseline ABS 3D printing speed and default for most printers, including Creality Ender 3. Even with high-speed 3D printers in the market, such as Bumbu X1 and Creality K1, ABS is typically done within this range.

Factors Affecting Limits

Nozzle temperatures

The nozzle temperature for ABS melting is typically 220-250°C. This nozzle temperature is higher than the most used printing filament, PLA. So, maybe the only tweak you can make here is to use a bigger nozzle and it must match what the heating element can do. The printer's capabilities generally constrain you, and that is why most printers opt for printer upgrades, such as a better heating element and a bigger nozzle.

Typically, most other filaments don’t require bed heating. For ABS, a bed temperature of 80-110°C can smoothen the process and help you get that much-needed first-layer adhesion.

Printer capabilities

The biggest print speed constraint is the printer. For example, printers will have direct drive or Bowden extruders. Some will handle faster layering. Also, other auxiliary features such as cooling fans, temperature enclosures, and bed quality will affect what you can or cannot do.

Risks of Going Too Fast

It is almost certain that if you go too fast with ABS, you will regret it. You are likely to get a warped or stringing product. ABS is prone to warping as a result of cooling and layer adhesion issues, poor layer bonding, and stringing.

Risks of Going Too Slow

You cannot go too slow. ABS will likely overheat, destroying the filament. You are not going to make anything good from a degraded filament. Lastly, it is plainly uneconomical to print for hours on end. Longer print times mean higher costs.

If you have all these limitations on your printing, consider upgrading to a more modern ABS printer. For example, the enclosed K1 3D printer with a heated bed can print ABS and ASA at 275°C at 300mm/s when using default ABS printing settings. That is significantly higher speeds.

Other Key Considerations for ABS Printing

Enclosure

One way of improving print speeds without affecting the results is by using an enclosure. What will an enclosure do? An enclosure keeps the internal printing temperatures relatively uniform, reducing rapid cooling issues. You can get a Creality enclosure for any of our 3D printers.

Minimize Cooling

Another method of improving ABS printing quality is to use minimal or no fans for best results. Why ABS hates rapid cooling. A great way of handling this is by covering the fan.

Bed Adhesion

There are different types of beds out there. Some print ABS better than others. Use PEI sheets, ABS slurry, or Creality’s glass beds. These are excellent beds. They are designed with adhesion in mind. They will give you better bed adhesion and can be heated. And when heated, they heat uniformly.

Post-Processing

Since fast processing will not give great results, you have better luck getting a nice final piece through post-processing. Acetone smoothing or sanding for speed-related imperfections does the trick for this filament.

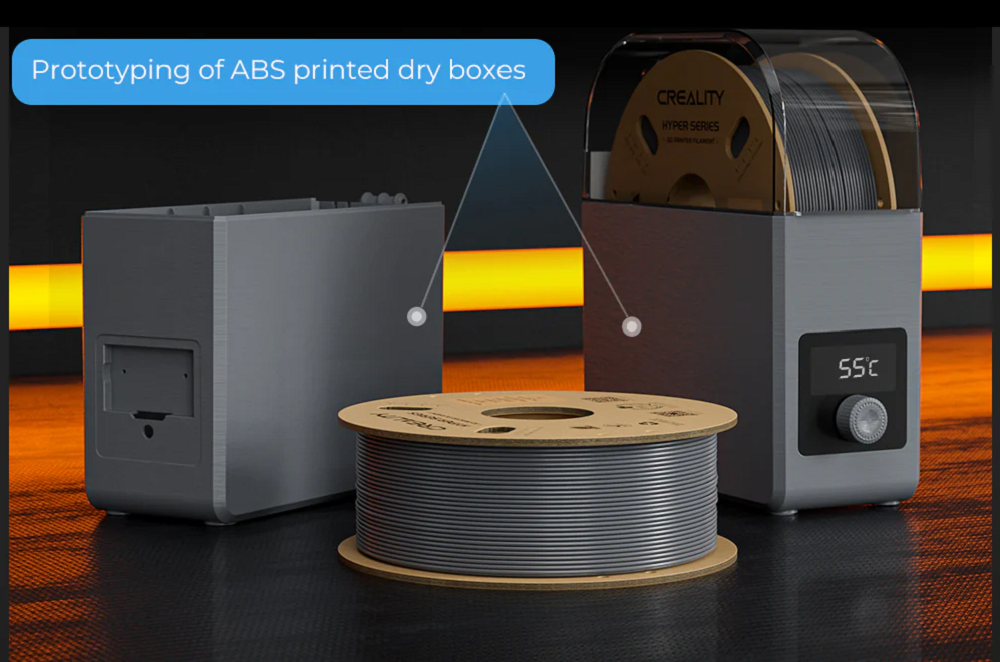

The most Practical Tip here through is, to balance speed with these factors for consistent ABS prints. When you go higher on speeds, add an enclosure, use better grade beds, heat the beds, and buy high-speed ABS filaments such as Creality’s hyper ABS.

Optimizing ABS Print Speed on Creality Printers

Ender 3 is a very popular printer, and the suggested settings for popular models are a print speed of 40 mm/s, a 240°C nozzle, and a 100°C heated bed. Throw it in an enclosure, and you have optimal output at speed. Creality’s hardware includes silent motherboards, and hot-end upgrades support ABS printing even for older printers.

Common Mistakes to Avoid

Printing ABS too fast without an enclosure.

You will most likely have issues with cooling and layer adhesion, and the quality will be bad.

Retraction Settings

Retraction settings are also essential to check before you start printing. Ignoring retraction settings can lead to stringing. If you are lucky and the stringing is not too much, you have a chance for post-processing. However, excessive stringing will surely damage the whole print. Remember, every stringing is a waste. If you want to make efficient prints in terms of resource use, these are some of the things you want to avoid. Different materials work differently. However, tests at 4mm retraction on ender three have shown a significant reduction in stringing when printing two points that are separate from each other.

Using inadequate bed prep

A good bed preparation includes optimal heating to prevent the print from detaching. Once the print detaches from the bed, you have no option but to stop the processing. That means lost filament and energy. Tests have shown that a heated bed will do the trick.

Conclusion

Custom printers and custom ABS filaments can achieve mind-blowing ABS print speeds. Though most shelf options typically print at 30-60mm/s, you can significantly improve speed by making several tweaks. Notably, some custom beds have better first-layer adhesion. When combined with bed heating, they improve overall quality by reducing rapid layer cooling, consequently reducing warping. Other necessary tweaks you can make include buying an enclosure and making changes to the retraction settings.

Are you ready to master ABS printing? Explore Creality’s ABS filament and printers at the Creality Store. If you have experimented with any or many other alternatives, share your ABS tips below with the community!