The automotive industry is changing – and it’s not just electric vehicles causing the shift. 3D printing is speeding up development. It makes it easier for car lovers, repair shops, and manufacturers to get parts.

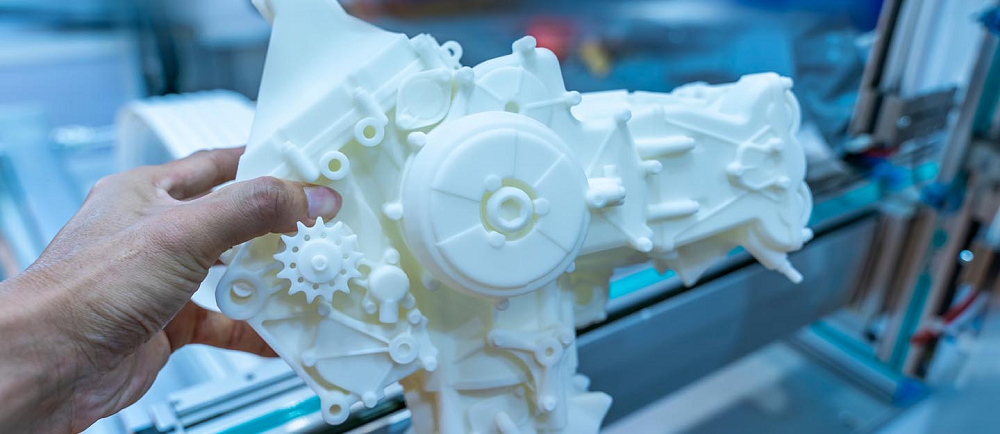

By 3D printing automotive parts, car manufacturers can develop complex components with high-quality prototypes faster and reduce waste. 3D printers are easy to find. This allows everyone, from classic car collectors to big car companies, to try out the technology.

At Creality, we offer many 3D printers. This makes it easy to start 3D printing car parts.

Whether you are a beginner looking for a new hobby or a car lover making replacement parts, we have what you need. Read on to find our beginner's guide to 3D printing vehicle parts. We will share ideas to help you get the most from your 3D printer.

Why Choose 3D Printing for Automotive Parts?

3D print car parts are useful for everyone. They help both big car makers and hobbyists who need replacements. There are three main benefits of exploring this technology and investing in a 3D printer.

Cost-Effective

3D print car parts are a cost-effective way to produce items as needed. This helps reduce inventory and cut down on waste. It’s easier for repair shops and manufacturers to create the exact parts they need when they need them. Unlike traditional manufacturing, 3D printing doesn’t require molds and dies, significantly reducing operating costs.

Flexibility and Customization

Customized cars are one of the biggest trends of the decade. Collectors and buyers want vehicles they can make unique. 3D printing car parts can be fully customized. It is easier to make prototypes directly from digital models.

Faster Production Cycles

Rapid prototyping with 3D printing gives designers and manufacturers their test parts within just hours. It helps drastically reduce the design-to-production timeline, particularly for low-volume and replacement parts. 3D printing gives flexibility to quickly implement changes into CAD software for faster turnaround.

We are already seeing 3D-printed car parts used in the industry. Ford says they have “saved billions of dollars and millions of hours of work” by using 3D printing.

How to Start 3D Printing Vehicle Parts

3D printing car parts starts with creating a digital file using a CAD program. Unlike traditional manufacturing, 3D printing gives product developers greater flexibility and a cost-effective way to experiment with customization and need designs.

esigning and Modeling Parts

You’ll need to start by choosing CAD software for designing your 3d models. AutoCAD, Fusion 360, and Tinkercad are among the most popular.

It’s important to think about the function and purpose of the part you are designing. Also, consider how it fits into the vehicle’s overall system.

When designing your 3D parts, think about durability. Also, consider the materials you will need. Finally, plan how they will fit together in the car.

Choosing the Right Materials

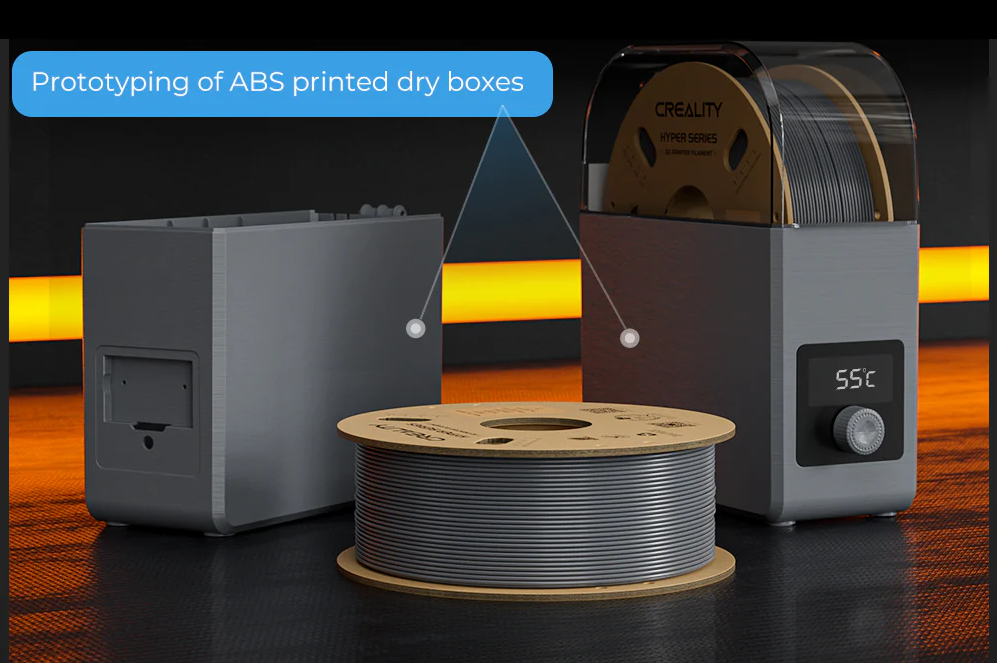

3D printing car parts requires a range of materials that reflect the different functions a part may play within a vehicle. Plastic filaments are great for early prototypes. They are easy to print. ABS, PLA, and PET-G are some of the most popular types.

PLA is suitable for dashboard components and upholstery as it has low thermal expansion and high impact resistance. By comparison, ABS is highly rigid, making it suitable for chassis parts, like 3D printing car body panels.

You can use plastic materials to make cheaper parts. However, for parts that need to resist heat and perform well, you will need metal materials. Titanium and stainless steel are good choices for engine components. Composite materials, including carbon fiber-reinforced plastic, can also be used for lightweight, durable 3D-printed car parts.

Choosing the Best 3D Printer for Car Parts

Not every 3D printer is suitable for making car parts. At Creality, our high-performance FDM printers are our top recommendation for 3D printing automotive parts. FDM 3D printing is highly accessible and uses fused deposition modeling for layer-by-layer construction.

Our Ender series 3D printer offers great quality at a low price. It is perfect for starting your 3D printing journey.

Take a look at our detailed guide on what to consider when choosing a 3D printer. This will help you find the best 3D printer for car parts that fits your manufacturing needs.

No matter which printer you pick, it’s important to adjust your printer settings. You should also calibrate your printer often. This helps make sure your designs are printed correctly.

What to Do After 3D Printing Your Automotive Parts

The process of successfully 3D printing automotive parts doesn’t stop once your printer finishes its task. There few extra steps that will improve the quality, strength, and overall aesthetic of your 3D-printed car parts.

- Cleaning: Gently remove the temporary structure printed along your 3D design, including removing the residual powder. Removing the support structures and cleaning your 3D parts will give you a smoother surface.

- Repairs: Check over your 3D parts to see if there are any small repairs needed, such as filling in holes or welding parts together.

- Curing: Curing your 3D parts will improve their strength and mechanical properties.

- Sanding and painting: You can improve the overall look of your 3D car parts by sanding and painting to achieve a cohesive look.

How to Choose the Best 3D Printer for Car Parts

Anyone can 3D print vehicle parts. This includes sports car companies like Porsche and classic car collectors making replacement parts.

It’s important to know what you need from a 3D printer. This will help you choose the best option for you. You should think about whether to buy your own 3D printer or use a 3D printing service.

While investing in your own 3D printer incurs more up-front costs, it gives you a faster turnaround time and oversight of quality control. A third-party service might be cheaper and more reliable if you only 3D print vehicle parts sometimes.

Create 3D-Printed Automotive Parts with Creality’s Ender Series Printers

3D printing is revolutionizing the automotive industry, making it more affordable to create replacement parts and drastically reducing product development timelines. If you make cars and want to reduce production and labor costs, 3D printing can help. If you love cars and need custom parts, 3D printing is also a great option.

It is the future of the automotive industry. Shop our 3D printers or contact our team for more help to find the best 3D printer for car parts.