An innovative supercar project driven by 3D printing

What is the limit of home 3D printing? Decrations and toys may come to mind. Yet Sterling Backus and his son Xander tell a fantastic story of bringing supercars into real life. Through 3D printing technology, they manage to restore and rebuild a Lamborghini and a Maclaren, redefining what’s possible with home 3D printing and catching the eye of Lamborghini itself.

From Virtual Racers to Real-World Makers

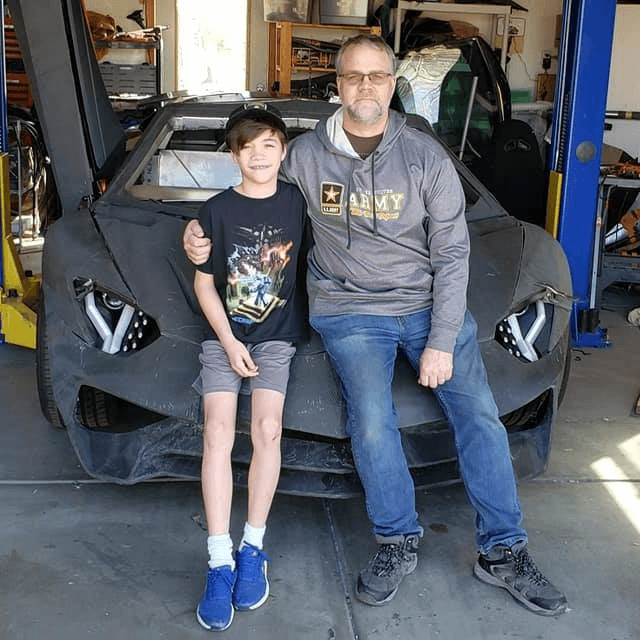

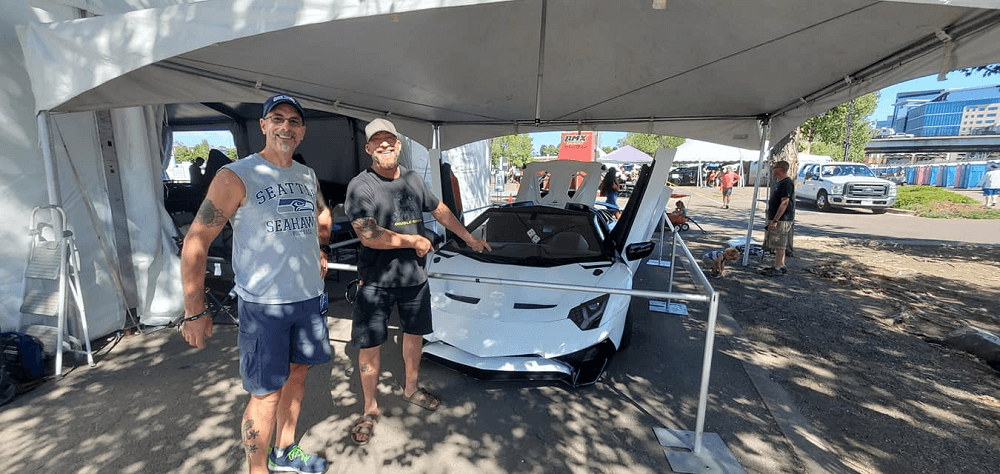

Sterling, Xander and their supercar model of Lamborghini Aventador

Sterling Backus, a PhD laser physicist, shares a love for video games with Xander. They often drive a Lamborghini Aventador in racing games on Xbox. One day, Xander asked his father if they could make a real Lamborghini on their own, after learning some automotive skills like welding and repair. As a curious kid, he found out that 3D printing had the magic to create everything. And Sterling saw the golden opportunity to teach his son how to build things in an adventure involving mechanics, technology and joy.

How Creality 3D Printers Realise Supercar Building

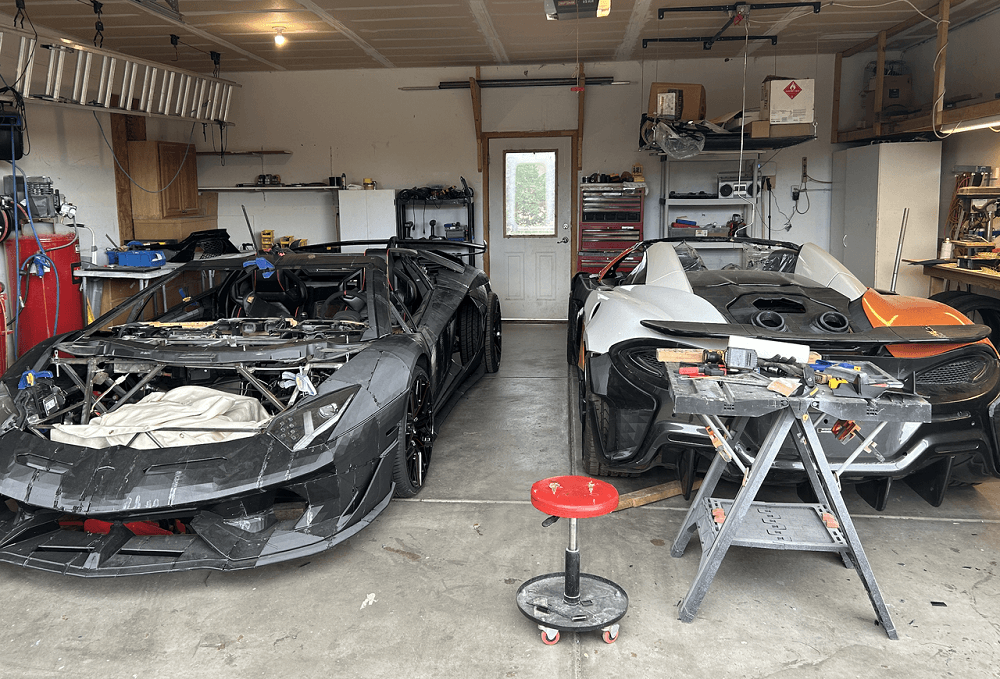

In their exploration, Sterling and Xander set their sights on two supercar projects. One was a Lamborghini Aventador SVJ, built entirely from scratch. The other was a McLaren 600LT, initially acquired from a scrapyard.

One key process of creating a car was to construct parts and components. However, OEM parts could be extremely expensive. A single headlight assembly for McLaren, for example, cost over $2,000. Custom mold tooling could take months to deliver and handcrafted parts lacked the precision needed for aerodynamic consistency.

Moreover, the project demanded a wide range of materials, from strong and rigid filaments for structural parts, to UV and weather-resistant materials for exterior components, as well as high-precision resin for delicate interior elements.

Sterling's two supercar projects in the garage—Lamborghini Aventador and McLaren 600LT

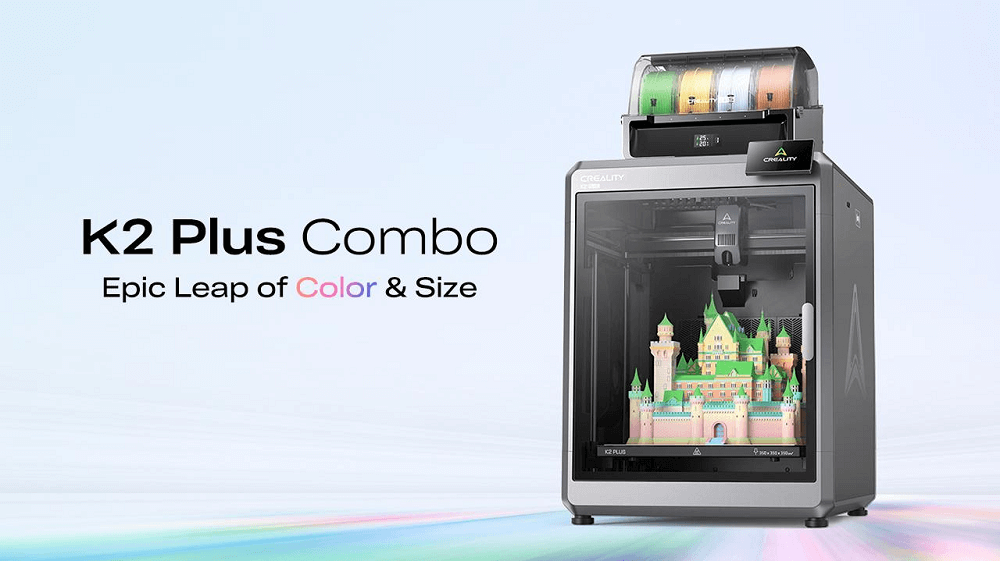

To overcome these challenges, Sterling built a highly efficient home production line using a suite of Creality 3D printers. The K1 Max, with its large 300×300×300mm build volume and high-speed printing up to 600mm/s, became his primary workhorse. Capable of printing with engineering-grade materials like carbon fiber nylon, the K1 Max was instrumental in producing key structures such as side skirts and mirror brackets. It drastically cut down production time, running up to three times faster than previous-generation machines. Sterling also used K2 Plus Combo, which perfectly met his needs for multi-color printing and even larger build volume—350×350×350mm, to print bigger automotive parts such as air intakes, rear wing, and front grilles.

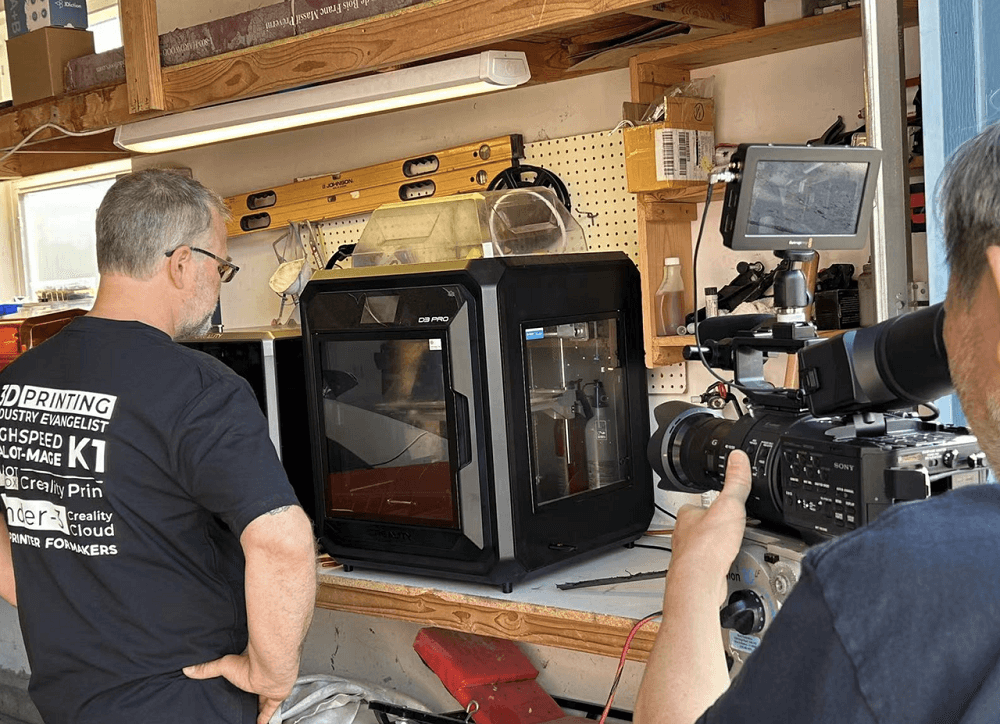

Sterling printing supercar parts with Creality Sermoon D3 pro

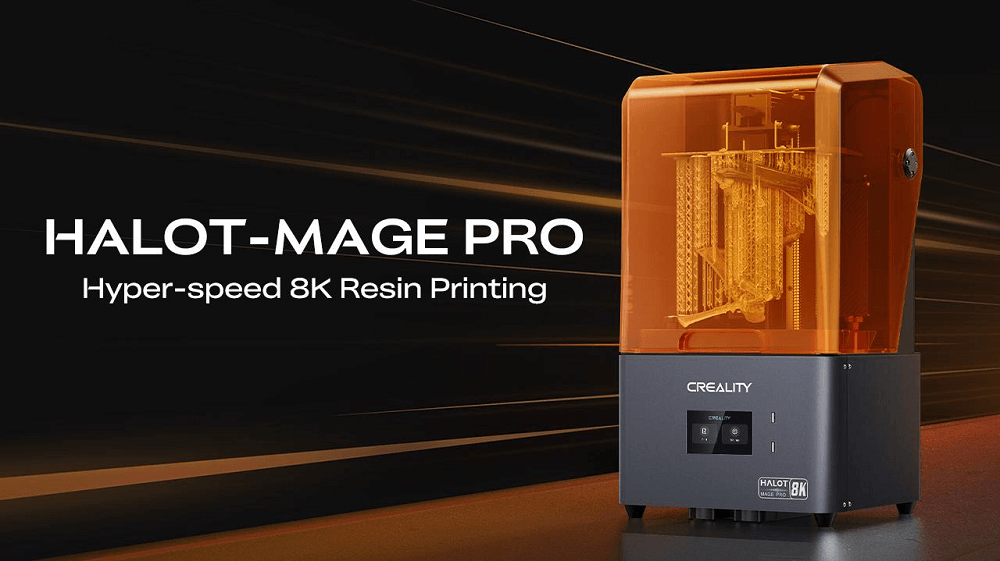

For components exposed to environment, Sterling applied Sermoon D3 pro, whose enclosed design to handle durable ASA filament made it ideal for printing bumpers, splitters, and other exterior structures. When it came to interior parts like headlights' internal structures or interior buttons, Sterling relied on a high-resolution resin printer, Halot Mage Pro, capable of achieving precision as fine as 0.05mm. It was notable that he also built and processed his own models using CAD software and slicer software Creality Print, which optimized production by generating intelligent support structures.

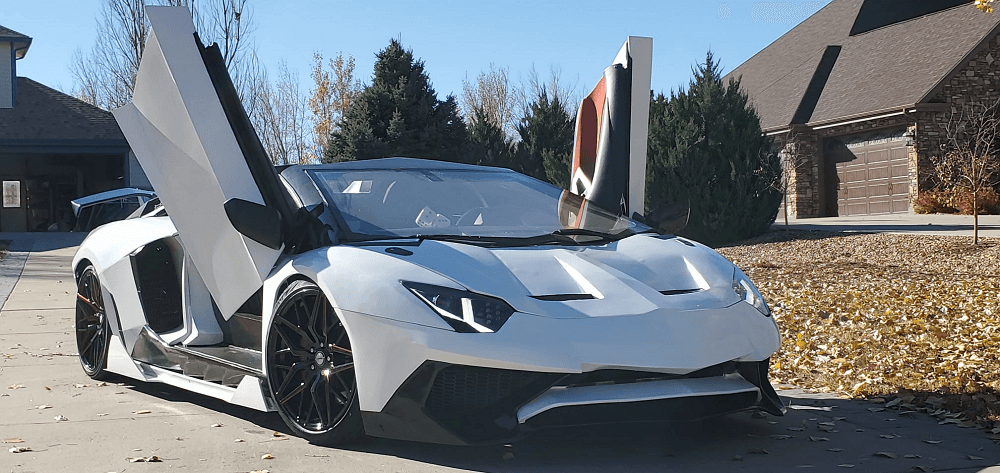

Whole bodywork of Lamborghini Aventador finished using 3D printers

After a long journey of hard work, Sterling's full-scale 3D printed Lamborghini Aventador became the first of its kind in the world. The build quality was impressive, with panel seams as thin as under 0.5mm and the finished body weight 15% lighter than stock.

Lamborghini Aventador after being painted, assembled and polished

Product Specifications

K1 MAX

-

Build Volume: 300×300×300mm

-

Printing Speed: ≤600mm/s

-

Filament Type: PLA/PLA+/Carbon fiber

-

Printed Items: Body panels, major load-bearing components

K2 Plus Combo

-

Build Volume: 350×350×350mm

-

Printing Speed: ≤600mm/s

-

Filament Type: PLA/PLA+/Carbon fiber

-

Printed Items: Decorative parts such as air intakes, rear wing, and front grilles

Halot Mage Pro

-

Build Volume: 228×128×230mm

-

Printing Speed: ≤170mm/h

-

Filament Type: Resin

-

Printed Items: Headlights, buttons

A Collabrative Commercial with Lamborghini

Sterling and Xander's amazing project quickly gained significant media attention, eventually leading to an unexpected call from Lamborghini's headquarter. Lamborghini was so impressed with the idea of 3D printing supercars and the pursuit of innovation and creativity along the adventure. The car maker then offered an exciting collaboration, inviting Sterling and his son to shoot a commercial for Lamborghini: A True Christmas Story for Lamborghini’s Real Lovers, which has now gained over 11 million views.

Building a Community, Inspiring the Next Generation

Following the successful commercial campaign, Sterling has launched a YouTube channel to share their car projects and showcase the versatility of 3D printing. As a growing community with 300% subscriber surge, the channel has gathered 3D printing and tech enthusiasts who could learn from each other and discuss their own prints. Sterling also envisions taking the printed cars to visit local schools and showing them on tour, in a hope to spark interest in the younger generation.

“You can actually now make usable pieces. Like you can make a coat hanger, you can make a bookshelf, you can do a lot of different things around the home. Not just 3D printing supercars.” Sterling expects.

Sterling displays his 3D-printed Lamborghini Aventador

More Than A Car: A Legacy of Innovation

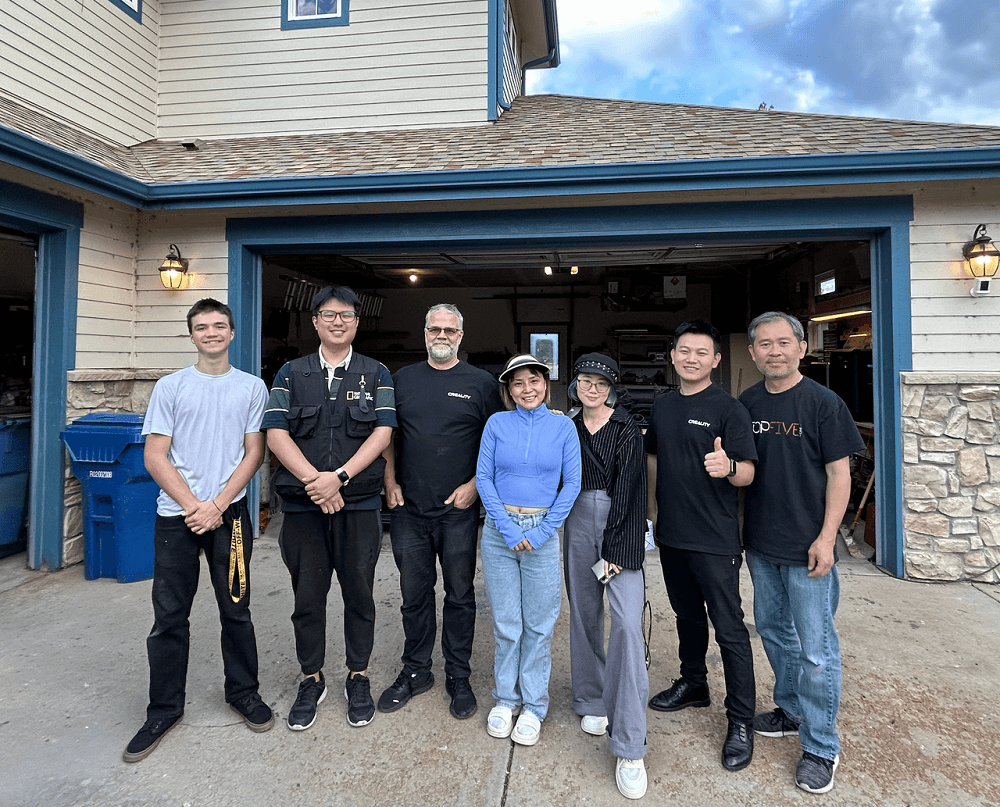

Sterling, Xander and Creality brand team

What makes this project extraordinary isn’t just the 3D-printed Lamborghini—it’s the story behind it. A father and son, united by curiosity, turned a video game fantasy into reality through cutting-edge 3D printing. Along the way, they proved 3D printing can put the power to create in the hands of anyone with a vision and made an inspiring example for young minds to imagine, innovate and embark on their own projects.