In STEM education, which cultivates the mindset and ability to solve realistic problems, smart and useable educational devices are essential for students' development—3D printers have been increasingly applied in classrooms nowadays. At Purdue University, its 3D Printing Club has transformed into a creative makerspace fueled by the partnership with Creality, a leading 3D printer maker, who has sponsored a batch of printers and scanners for purpose of releasing multi-disciplinary potential for students through accessible technology.

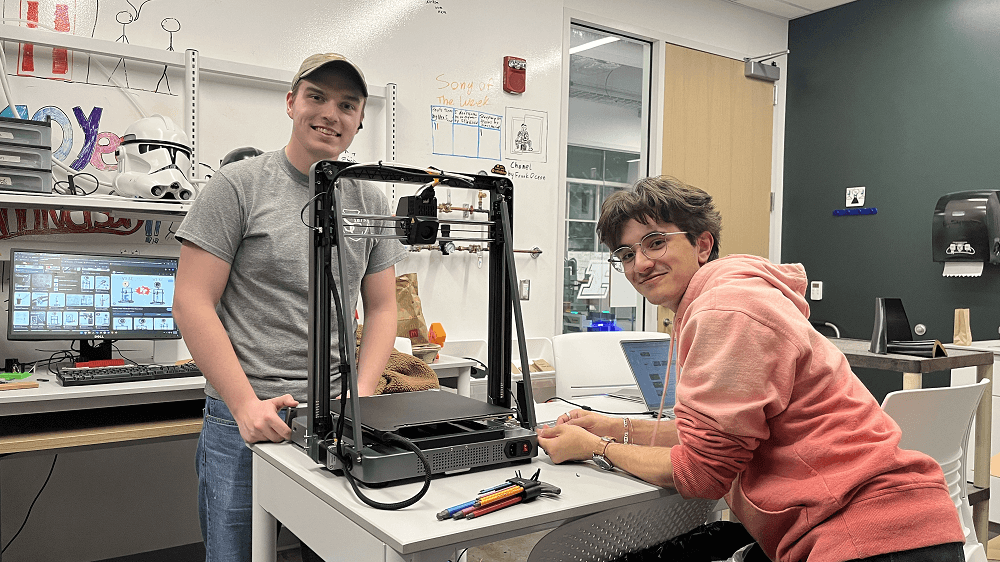

3D Printing Club members and Creality's 3D printer

Dedicated to providing access to 3D printing in coursework, research projects, design competitions and entrepreneurial efforts, Purdue 3D Printing Club has helped hundreds of students across various disciplines of science, engineering, design, architecture, etc. In an average semester, the club handles over 1,000 print tasks, such as making robots, designing biomedical devices, and testing startup prototypes. The club has played a vital role in fostering students to step from textbooks to practices.

However, urgent needs emerged to upgrade machines after the club was operated for some time. Outdated and unreliable printers often resulted in failed and repeated prints and required extra manual calibration. There's also a lack of standardized training on workflow from modeling to manufacturing, and digital management to track printer and filament use.

A Donation from Creality to Encourage STEM Students

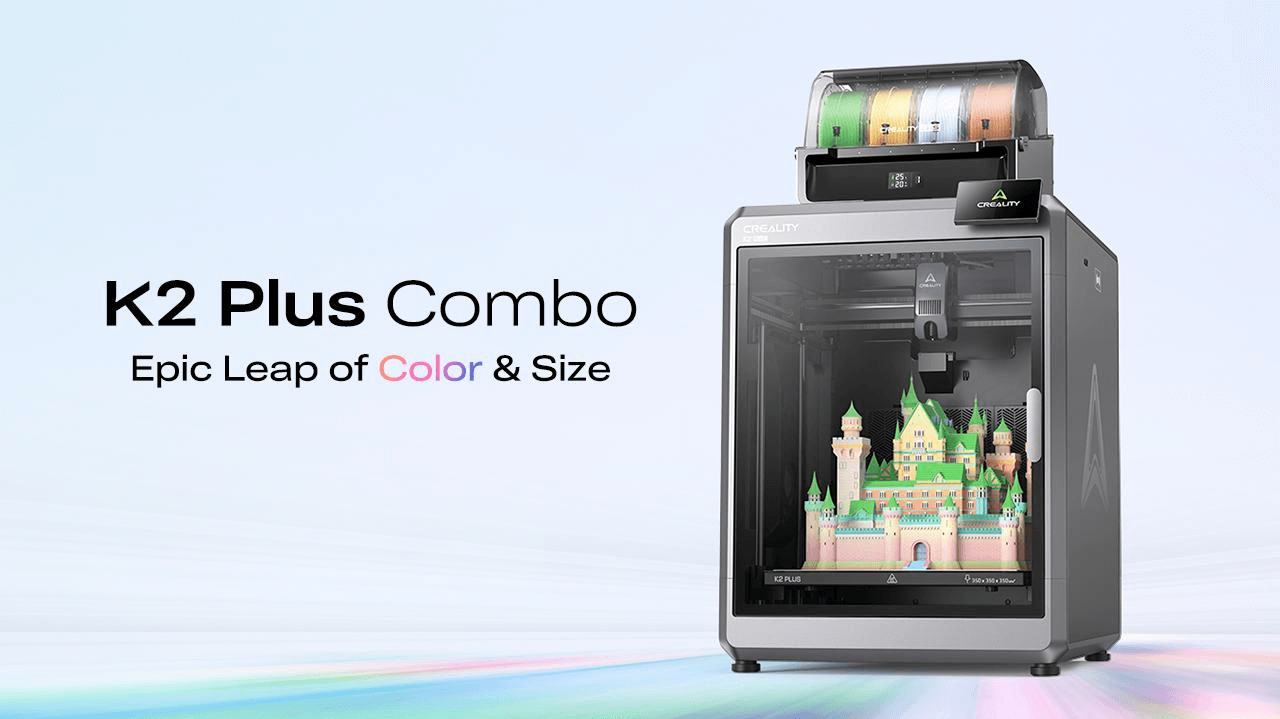

As a responsible 3D printer producer, Creality has always given top priority to education, STEM in particular, across over 100 countries and regions in a vision to make the world a better place. This year, Creality reached out to Purdue University and partnered with the 3D Printing Club in a donation of 3D printers—K2 plus, Ender-3 V3 Plus and K1 Max, and scanners Ferret Pro. Other donations also included filament, filament dryer and product manual. Creality dreams that inclusive technologies will make a difference for each and every student to ignite curiosity and creativity.

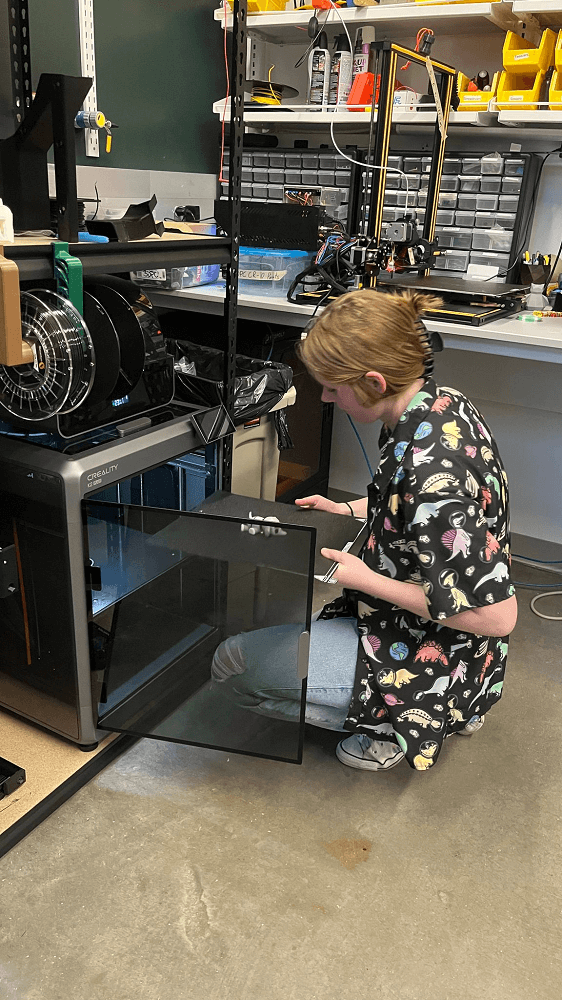

A club student taking out her printed model from Creality K2 plus machine

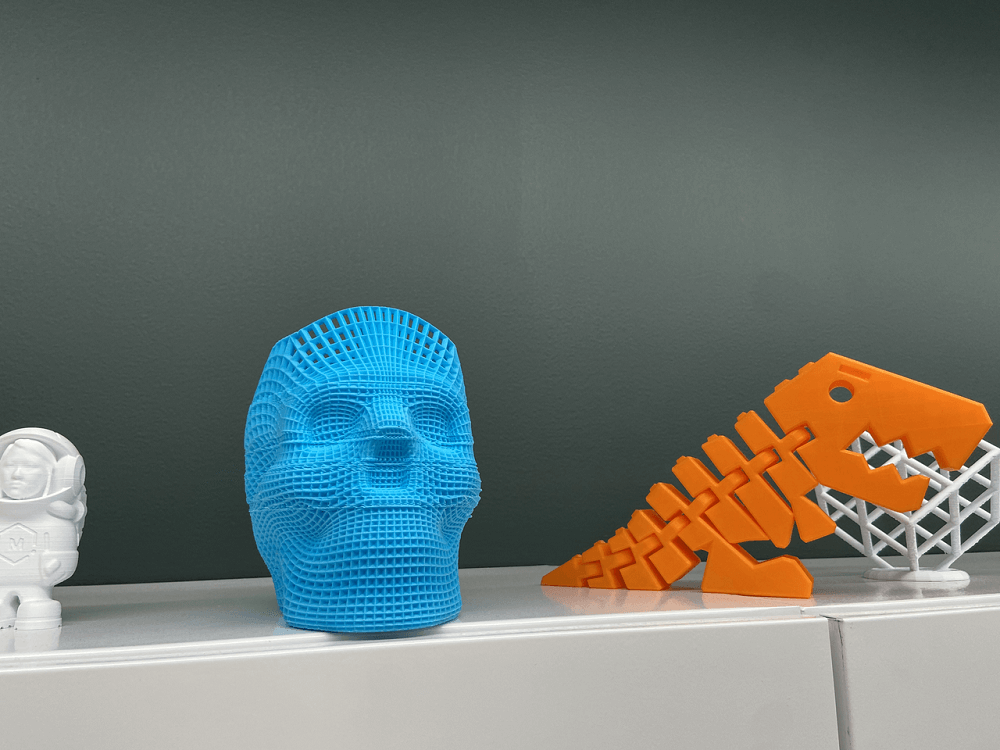

With excellent features—speedy, stable, easy-to-use, and compatible with a broad range of materials, Creality printers enhanced the monthly print volume in the club by threefold within a year—from approximately 200 to over 600 pieces per month, and decreased the turnaround time from 3 to 5 days to under 48 hours. With higher print efficiency and quality, members and students were enabled to try different ideas for their assignments and research projects. In the support of Creality Print and equipped technical documents, they were also trained to learn about a complete workflow mechanism from scanning, modeling to making and tracking, as well as two primary 3D printing technologies—Fused Deposition Modeling (FDM) and 3D capture. Their printed items now have been collectively showcased on the gallery of club's official website, such as helmets, engineering fountains, and animation characters.

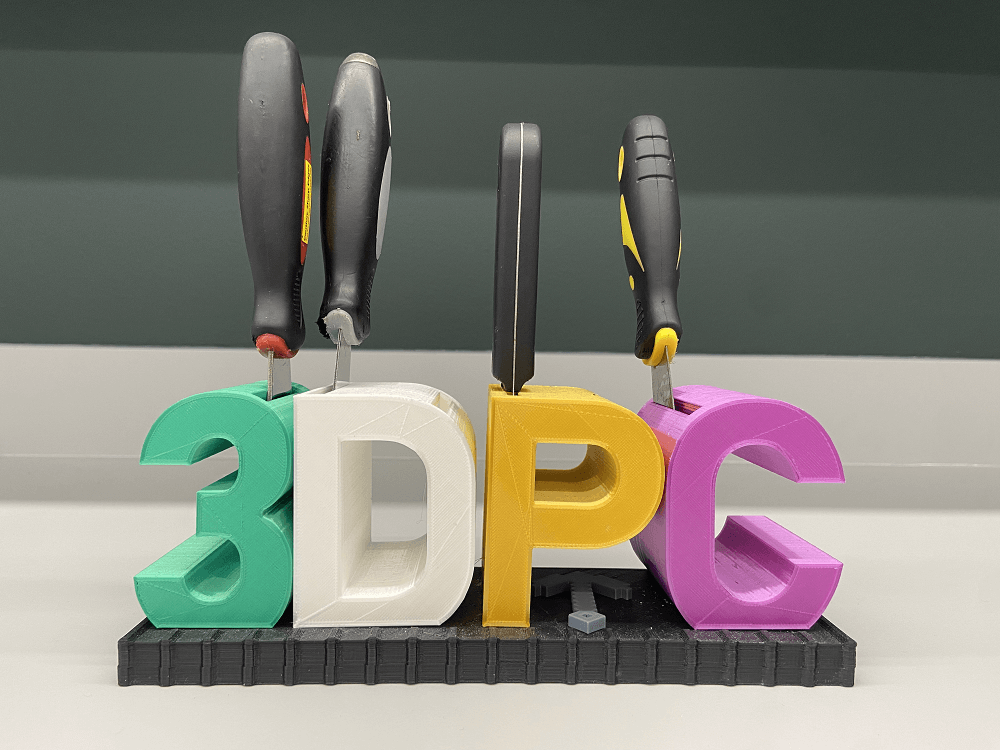

3D-printed 3DPC

Notably, a student team employing Creality printers won the first place in Purdue’s Robotics Club spring design competition, and presented their work at the Purdue Undergraduate Research Expo.

"The donation from Creality completely transformed our lab—students who had never touched a printer before are now building real-world prototypes in days." —Rick, Purdue Engineering Honors Program&3DPC Mentor.

3D-printed models

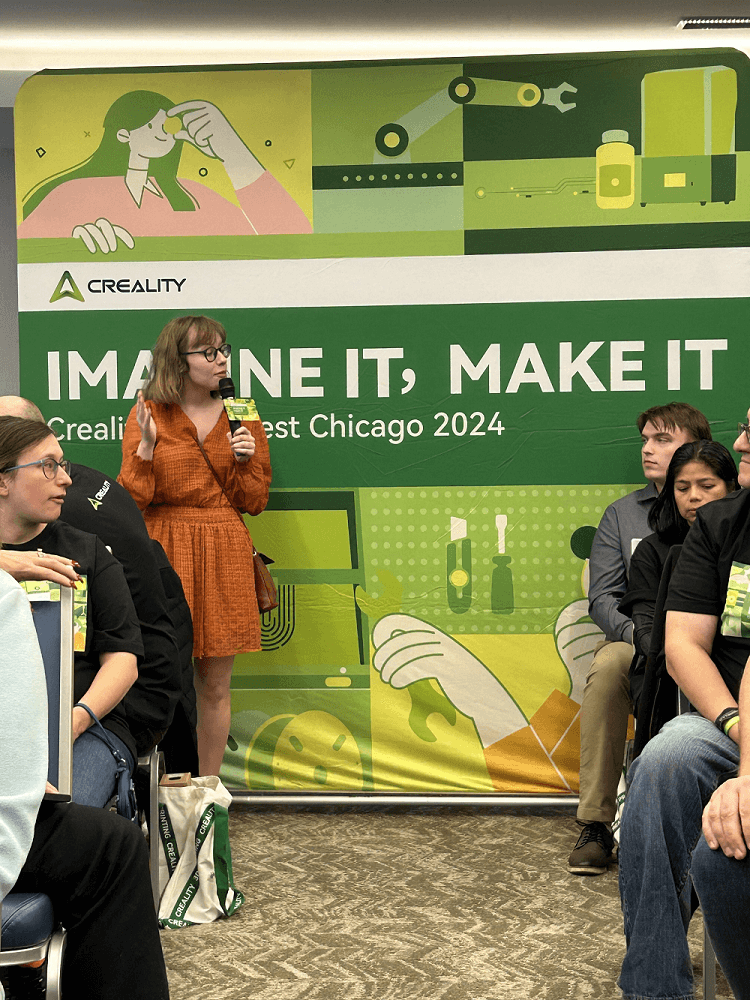

Additionally, the club was invited to present its workflow and innovative stories at Creality ShareFest Chicago, a fun user get-together event where stories were shared and new printer products introduced.

"At the ShareFest Chicago, the Creality K2 Plus really impressed our leadership team, especially its build volume that would solve our size issues and its capability of faster printing speeds that would allow us to increase the number of people who can print in our lab each day. The added benefit of excellent stability and precision would be also appreciated as we occasionally have requests for high quality prints." —Purdue 3D Printing Club members

Daisy, former club president , gave a speech at Creality ShareFest Chicago

3D Printing: Cultivating Tomorrow’s Innovators

With the help of 3D printing technology, learners in campus start to turn prototypes into real objects. In this way, they are able to test their ideas and iterate models at a very low cost. More importantly, they develop the ability to build the world and solve problems at an early age, and hopefully in the future tackle more complicated real challenges that matter to human society—those in technology, industry, engineering, health, environment, and more.

Product Specifications

K2 Plus

-

Build Volume: 350×350×350 mm

-

Printing Speed: ≤ 600 mm/s

-

Filament Type: PLA, PETG, ABS, ASA, PET, PLA-CF

K1 Max

-

Build Volume: 300×300×300 mm

-

Printing Speed: ≤ 600 mm/s

-

Filament Type: ABS, PLA, PETG, PET, TPU, PA, ABS, ASA, PC, PLA-CF, PA-CF, PET-CF

K2 Combo

K2 Combo