It’s the question on every beginner’s mind: What’s the best 3D printer? Studies show that 90% of 3D printer buyers kick off their journey by typing this exact phrase into a search engine. It’s a natural starting point—who doesn’t want the best?

But here’s what happens next: you’re hit with a tidal wave of “Top 10 3D Printer Lists.” Names like Creality, Bambu Lab, and Prusa pop up everywhere. Each brand touts itself as the “industry benchmark,” while reviews wave the flag of “trust us, buy this one!” It’s a dizzying parade of options, each claiming superiority.

Pause for a second—are these printers actually the ones you need? Or are you just wading through a sea of recycled recommendations, spoon-fed by big data algorithms? The more you scroll, the murkier it gets. What’s real insight, and what’s just clever marketing?

Fear not! This 2025 3D Printer Buying Guide, straight from Creality’s official website, is here to cut through the chaos. No blind hype, no generic lists—just practical, tailored advice to help you find the 3D printer that fits your needs like a glove. Let’s get started!

Your Shortcut to the Perfect 3D Printer

To help you zero in on the 3D printer that’s just right for you, Creality has distilled the essentials into 9 must-know tips for buying a 3D printer. These insights will streamline your decision-making, boost efficiency, and ensure you pick a printer that truly fits your needs—faster and smarter than ever.

Tired of starting from square one every time you search? Save this guide and share it with your friends—it’s your go-to resource for cutting through the clutter and finding your ideal 3D printer with confidence!

Now, let's check out 9 3d printer buying guides.

1.Types of 3D Printing Technology

There are many types of 3D printing technologies, such as FDM, SLS, SLA, DLP, SLM, MJF, among which the following are the most common.

FDM (Fused Deposition Modeling): The most common and budget-friendly option, FDM printers like the Creality Ender 3 series melt filament (e.g., PLA, ABS) and layer it to form objects. They’re versatile, easy to use, and perfect for beginners or functional parts.

SLA: Resin 3d printers, such as the Creality Halot-Mage Pro, use UV light to cure liquid resin, delivering unmatched detail for small, intricate models like jewelry or miniatures. They’re pricier and messier but excel in precision.

SLS (Selective Laser Sintering): SLS are industrial-grade and use powdered materials—great for durable parts but less common for home use.

DLP (Digital Light Processing): Similar to SLA but faster, DLP cures resin using a digital projector. It strikes a balance between speed and detail, making it great for small-batch production or high-resolution models.

SLM (Selective Laser Melting): These heavy-hitters melt metal powders into fully dense parts, catering to aerospace, automotive, and medical industries where strength and precision are non-negotiable.

MJF (Multi Jet Fusion): A high-speed, high-quality option from HP, MJF fuses powder with binding agents, excelling at producing tough, detailed parts in bulk—perfect for advanced prototyping or small-scale manufacturing.

3D Printing techniques comparison

| FDM | SLA | SLS | DLP | SLM | MJF | |

| Operation principle | Extrusion Modeling | UV Laser curing | Laser sintering | Digital projection curing | Laser melting | Adhesive + Hot Melt |

| Material printed | Thermoplastic polymer in the form of string ( PLA, ABS) | Photosensitive resin | Powder (nylon) | Photosensitive resin | Metal powder | Powder (nylon) |

| Advantages | Low cost and easy to use | High precision and smooth | No support required, durable | Fast speed and high precision | High strength metal parts | Fast, mass production |

| Disadvantages | Low precision and rough surface | Expensive materials and complicated post-processing | Expensive equipment, powder recovery | High cost and narrow application scope | Expensive and complicated to operate | High equipment cost |

2.Print Resolution:How to Achieve High-Detail 3D Prints?

Print resolution plays a crucial role in determining the surface finish and level of detail in your 3D-printed models. It is measured in microns (µm), with lower values indicating finer detail and smoother surfaces.

-

Standard FDM resolution: 100–200 microns– Suitable for functional prototypes, large prints, and general-purpose models. Some high-end FDM printers offer resolutions as low as 50 microns for improved detail.

-

High-detail SLA resolution: 25–50 microns– Ideal for printing intricate designs, miniatures, jewelry, and dental models with ultra-smooth surfaces and sharp details.

-

Professional SLS resolution: 50–100 microns– Offers excellent mechanical strength while maintaining a balance between resolution and durability, making it a preferred choice for industrial prototypes and end-use parts.

For precise, high-quality prints, look for printers with adjustable layer height settings, as they allow you to fine-tune the balance between speed and detail.

3.Build Volume: how to choose a 3d printer size for your projects?

Size matters when it comes to 3D printing. Build volume—the maximum dimensions a printer can handle—determines what you can create in one go. Here’s what to look for in a 3D printer’s build volume:

Small 3d printer( 220 x 220 x 250 mm): The Ender 3 V3 SE is ideal for compact projects like toys or small prototypes.

Medium 3d printer( 300 x 300 x 300 mm): The Creality K1 Max offers room for larger models or multiple parts at once.

Large 3d printer( 350 x 350 x 350 mm): The K2 Plus is a beast for oversized prints like cosplay props or architectural models.

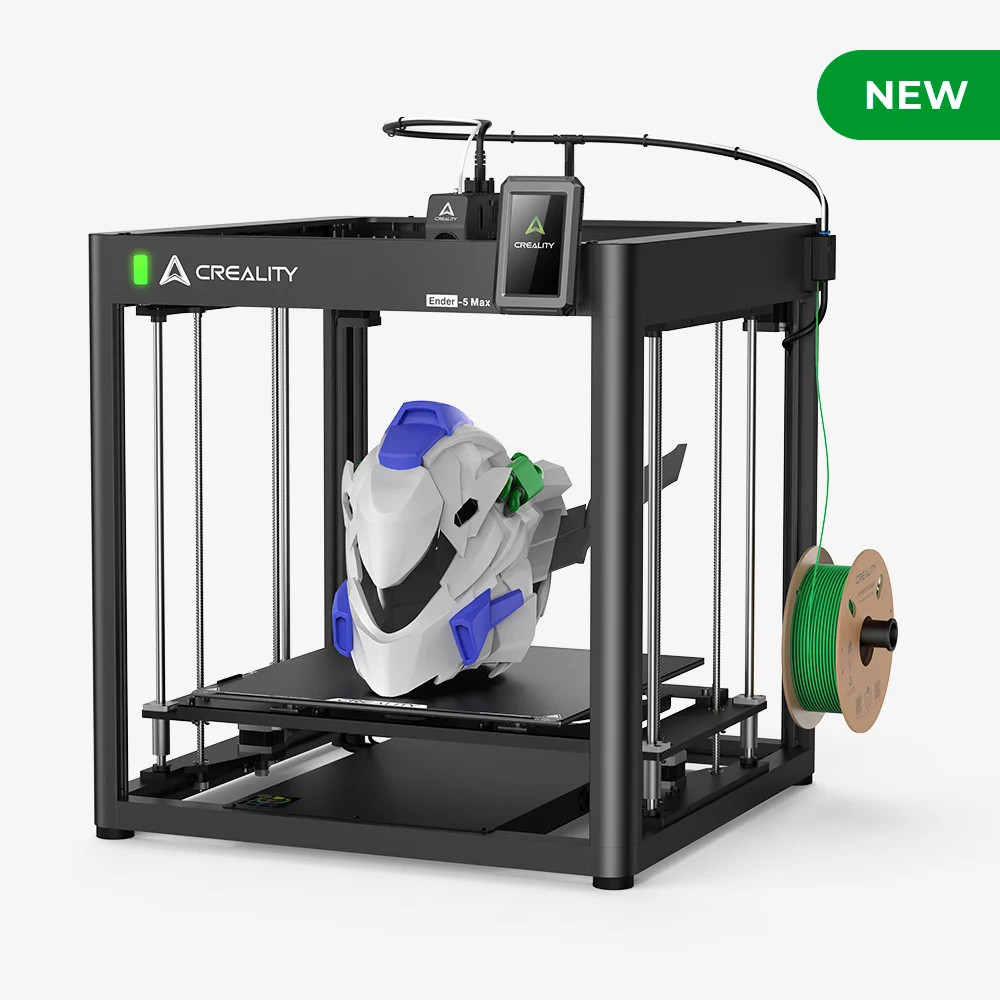

Extra Large 3d printer( 400 x 400 x 400 mm): The enormous build volume of Ender-5 Max is rarely seen in today's professional bed droppers. Whether you are printing small parts in batches or creating a huge model in one piece, Ender-5 Max is the no-brainer for its industry-level print volume.

4.Print Quality and Speed: Precision Meets Productivity

When evaluating what to look for in a 3D printer, print quality and speed are make-or-break. Here’s the breakdown:

Quality: Measured in layer height (e.g., 0.1 mm for fine details vs. 0.3 mm for faster prints), higher resolution means smoother finishes. Most Creality printers offer adjustable settings for this balance.

Speed: Modern printers like the Creality K1 boast speeds up to 600 mm/s, cutting print times drastically without sacrificing quality, thanks to features like input shaping.

For hobbyists, the Ender 3 V3 KE’s 250 mm/s is plenty fast. Professionals needing rapid turnarounds should prioritize speedier models. Test prints, like the classic 3D Benchy, can help you gauge a printer’s precision—try one on a Creality machine to see the difference!

5.Price and Budget: What’s the Best Value?

3D printers range from budget-friendly to professional-grade. Here’s a rough breakdown:

Entry-level ($200–$500): Great for beginners, hobbyists

Mid-range ($500–$1500): Better quality, larger build volumes

High-end ($2000+): Industrial and professional use, high precision

Example: The Creality Ender-3 V3 is an excellent budget-friendly FDM printer, while the Creality K1 Max is designed for professional users.

6.Material Compatibility: What Can It Print?

Not all 3D printers handle every material, so material compatibility is a key factor in what to look for in a 3D printer. Common 3d print filaments include:

PLA: Eco-friendly, easy to print, and perfect for beginners (supported by all Creality FDM printers).

ABS: Tough and heat-resistant, ideal for functional parts but requires a heated bed.

PETG: A balance of strength and flexibility, great for versatile use.

TPU: Flexible filament for soft, rubber-like prints—needs a direct-drive extruder like the Sprite on the Ender 3 S1.

Advanced users might explore nylon or carbon-fiber composites, which demand higher temperatures and enclosed designs (e.g., the Creality K1C). Check the printer’s hotend temperature (up to 300°C on our premium models) and enclosure options to match your material goals.

7. Heated Bed and Enclosure: Stability Matters for Reliable Prints

A heated bed and enclosed build chamber play a crucial role in print stability, adhesion, and overall success, especially when working with temperature-sensitive filaments. Choosing the right setup can make a significant difference in print quality and material compatibility.Whether you’re a beginner sticking to PLA or a pro experimenting with trickier filaments, here’s why these features matter and how they shape your printing experience.

The Power of a Heated Bed

What It Does: A heated bed warms the print surface, helping materials stick firmly during printing and cool evenly afterward. This cuts down on warping—those those frustrating curls or lifts at the edges of your model.

Key Materials:

- ABS: Loves heat (typically 90–110°C) to stay flat and strong. Without it, you’re battling cracks and detachment.

- PETG: Needs a moderate 70–80°C to adhere well and avoid stringy messes.

- PLA: Works fine cold but benefits from 40–60°C for better first-layer grip.

Why It Matters: No one wants a print to peel off mid-job or end up warped like a potato chip. Most Creality printers—like the Ender 3 series—come with heated beds as standard, often reaching up to 100°C or more, giving you flexibility across common filaments.

Bonus: Some models offer textured or magnetic beds for extra adhesion—check specs for these perks!

Enclosures: Taming the Environment

-

What It Does: An enclosure traps heat and shields your print from drafts, creating a stable bubble for temperature-sensitive materials. It’s like a cozy greenhouse for your 3D printer.

-

When You Need It:

-

ABS: Emits fumes and demands steady warmth (around 40–50°C ambient) to avoid splitting or warping.

-

PETG: Benefits from enclosure to prevent cooling too fast, which can weaken layers.

-

High-Temp Filaments (e.g., Nylon, PC): These divas need enclosures to hit their stride—think 60°C+ for pro-grade results.

-

-

PLA Exception: PLA plays nice in open air, though an enclosure can still refine results in chilly rooms.

8.Connectivity and Software Compatibility

Look for a printer with multiple connectivity options such as:

-

USB and SD card – Standard for offline printing

-

Wi-Fi and Ethernet – Ideal for remote monitoring and control

Also, ensure that the printer is compatible with popular slicing software like:

-

Cura (popular for Creality printers)

-

PrusaSlicer

-

Simplify3D

9.Community and Support: Who’s Got Your Back?

A strong community and reliable support are often overlooked but critical in what to look for in a 3D printer. Creality shines here:

Community: With millions of users worldwide, our forums and Creality Cloud offer endless tips, models, and troubleshooting advice.

Support: Our official store provides warranties, spare parts, and responsive customer service.

Reputation: Creality’s track record—think the iconic K2 Plus—means you’re investing in a trusted brand.

Finally

Buying a 3D printer becomes easier when you have a clear, repeatable process to follow. These SOPs help you work faster, stay consistent, and get better results - without the guesswork.

Is there a 3D printer option that is right for you? Creality has 3D printers suitable for both beginners and experienced users, and I would be happy to help you choose the right machine!