Introduction: 3D Printing is Changing the Eyewear Industry

The eyewear industry is undergoing a profound transformation driven by the rising demand for customization, sustainability, and faster production. Consumers today are seeking glasses that not only fit perfectly but also express their unique style without compromising on comfort or ethics. At the same time, manufacturers are under pressure to minimize waste and streamline supply chains. This shift has opened the door for an exciting innovation: 3D printing.

Additive manufacturing, or 3D printing, is rapidly disrupting traditional eyewear production methods by allowing brands and individuals to 3D print glasses with unparalleled design freedom, minimal material waste, and local, on-demand fabrication. From creating bespoke frames tailored to facial scans to producing lightweight prototypes within hours, the 3D printing technology offers a level of agility that conventional methods can’t match. From luxury fashion houses to independent opticians, many are now embracing the ability to 3D print glasses frams eyewear at scale or on a made-to-order basis.

3D printing is now one of the most talked about innovations in the eyewear industry.

Why Use 3D Printing for Glasses and Eyewear?

1. Custom Fit and Personalization

Among the advantages of using 3D printing in eyewear is the ability to create 3D printed glass frames that are fully tailored to an individual’s facial features, lifestyle, and taste. By employing facial scanning and parametric design software, eyewear makers can adjust frames for nose bridge width, temple length, head shape, and even ear positioning. This ensures unmatched comfort and aesthetics.

2. Faster Prototyping and Production

Traditional eyewear manufacturing involves a long and rigid process of mold creation, CNC machining, and multi-stage finishing. These processes often take weeks or months to finalize a single product. With 3D printing, designers can 3D print glasses prototypes within hours and iterate rapidly, which reduces development timelines drastically.

3. Lower Costs and Reduced Waste

Conventional production, such as subtractive manufacturing, often involves cutting materials from large sheets or blocks, which leads to substantial waste. In contrast, 3D printing eyewear is additive, which means it builds only what’s needed, layer by layer, thus reducing material usage significantly.

The ability to 3D print glasses combines design freedom with lean production principles offering a smart, sustainable, and customer-centric alternative to traditional manufacturing.

What Parts of Eyewear Can Be 3D Printed?

Thanks to advancements in materials, precision printing technologies, and generative design software, virtually every component of eyewear can now be manufactured using 3D printing.

3D Printed Glass Frames

The frame is the centerpiece of any pair of glasses and is also the easiest to customize through 3D printing. Today, 3D printing allows eyewear makers to produce 3D printed glass frames that are tailored to the wearer’s precise facial geometry, preferences, and even lifestyle needs.

Being able to 3D print glasses frams eyewear has unlocked a new realm of possibilities for creators and manufacturers.

3D Printed Eyeglass Arms (Temples)

Temples, commonly called eyeglass arms, play a crucial role in comfort and stability. With 3D printing, these components can be engineered for optimal flexibility, grip, and modularity.

Additive manufacturing allows for highly ergonomic designs with adjustable hinges, flexible joints, or integrated spring elements, all printed in a single part without assembly. Materials like flexible TPU allow brands to 3D print eye glass arms that are both strong and bendable, resisting breakage even under stress.

3D Printed Sunglasses

Fashion meets function in the world of 3D printed sunglasses, where bold aesthetics and cutting-edge materials come together. With additive manufacturing, designers can push boundaries, creating sculptural, futuristic, or nature-inspired designs that are impossible to mold traditionally.

Best 3D Printers and Materials for Eyewear

Whether you're making fashion-forward 3D printed glass frames or prototyping ergonomic temples, your results will depend heavily on the capabilities of your printer and the performance of the material used.

Here are the top-performing printers and materials for eyewear fabrication.

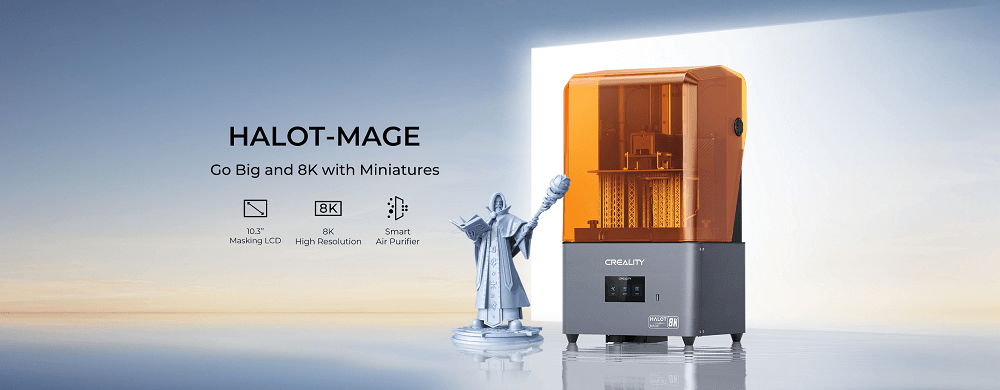

-

Custom eyewear studios

-

High-end fashion frames

-

Small-batch boutique runs

-

Prototypes with tight tolerances

It’s compatible with smooth resins for a polished, skin-friendly finish.

Creality fiagship Series (K2 Plus Combo, K2/K2 Pro Combo): Best for Functional Prototypes & Hinged Components

For those seeking a balance between precision and rugged functionality, the Creality Fiagship series offers a trusted and upgradeable FDM platform for eyewear development. These machines are especially effective when testing 3D printed glass frames for fit, strength, or flexibility.

Their open filament system and affordability make them ideal for design studios, educators, and independent creators getting started in 3D printing glasses.

Ideal for:

-

Durable test prints

-

Hinges and modular arms

-

Entry-level or production-grade frame iterations

Print with TPU, PETG, and nylon.

Best 3D Printing Materials for Eyewear

-

Resins (Standard & Flexible): Ideal for smooth, skin-contact frames and intricate detailing.

-

Nylon (PA11/PA12): Excellent durability, lightweight, hypoallergenic.

-

TPU: Flexible and impact-resistant; great for temples and hinges.

-

PETG: Strong, semi-flexible, and easy to print with. Suitable for testing frame ergonomics and load-bearing design elements.

Step-by-Step: How to 3D Print Glasses

Below is a proven step-by-step process that reflects how today’s innovators create 3D printed glass frames and eyeglass arms with professional-level precision.

1. Design the Eyewear (CAD Modeling)

The process begins with designing your eyewear in CAD software such as Fusion 360, Blender, or Rhinoceros 3D. These tools allow you to model precise frame fronts, temples (arms), hinges, and nose bridges while accounting for comfort, ergonomics, and lens size compatibility.

2. Separate Parts: Frame, Arms, Hinges

Before printing, it's best to separate your model into components:

-

Frame front (housing the lenses)

-

Temples (eyeglass arms)

-

Hinge joints or clip connectors

This allows for optimized printing orientation, fewer support structures, and easier post-processing. If you 3d print eye glass arms separately, you can even experiment with flexible materials or modular designs.

3. Choose the Right Material and Printer

The right printer and material depend on your goals:

-

Resin printers (like Creality Halot-Mage) are perfect for high-detail, smooth 3D print glasses frams eyewear.

-

FDM printers (like Creality K2 Plus Combo) work well for durable, testable frames and arms using PETG, TPU, or Nylon.

-

SLS printers are ideal for high-performance nylon frames with no supports needed.

Material options:

-

Resins are great for aesthetic and skin-contact comfort

-

PA11/PA12 Nylon is durable, flexible, and hypoallergenic

-

TPU is perfect for flexible temples and hinges

-

PETG is semi-flexible, strong, and easy to prototype

4. Post-Processing: Polishing, Dyeing, Assembling

After printing, your components need cleaning, polishing, and finishing. This step transforms a raw print into a professional-grade product:

-

Resin prints require alcohol rinsing, UV curing, and sanding.

-

SLS nylon prints are typically sandblasted and dyed (popular for fashion eyewear).

-

FDM prints may be vapor-smoothed (with acetone for ABS) or polished manually.

After finishing, assemble the frame by attaching the 3d printed eye glass arms using metal or printed hinges, depending on your design. You can also add branding, texture, or rubberized coatings during this step.

5. Fit and Attach Lenses

Finally, insert the lenses, either manually or by heating and flexing the frame slightly to fit. For production-grade eyewear, partnering with an optical lab ensures correct lens cutting and secure fitting.

Why Choose Creality for 3D Printed Eyewear Projects

When it comes to transforming eyewear designs into real, wearable products, Creality stands out as the go-to brand for makers, startups, and designers around the world. Whether you're crafting high-end 3D printed glass frames or flexible eyeglass arms for active wear, Creality offers the tools, support, and reliability to bring your vision to life.

Affordable, High-Precision 3D Printers

Unlike many professional-grade 3D printers that require a steep investment, Creality makes industrial-grade quality accessible. With options like the Halot-Mage resin printer for ultra-smooth detail and the flagship Series FDM printers for tough, functional parts, you can achieve stunning results without breaking the bank.