Integral Light Source – “Core Engine” of Creality’s Resin 3D Printers

As we know, most resin 3D printers are designed with the Parallel Emission technology. However, some feedback reflects that joint places have less lighting intensity which results in unevenness, and broken LED units will easily influence the model’s precision. That’s why users find it challenging to print perfectly sometimes.

To solve this problem and optimize the user experience, the R&D team of Creality has delved into research and strived for technological breakthrough. This year, Creality successfully releases new resin 3D printers, which have adopted the new generation Integral Light Source technology. Featured by stronger lighting intensity, remarkable lighting evenness and ultra-high printing precision, new generation Integral Light Source technology is developed to be impressive.

Why Integral Light Source?

Lighting Evenness

Parallel Emission, as a technology commonly used in resin 3D printers, uses a UV LED matrix and LED units’ well-functioning plays a significant role in successful 3D printing. Therefore, if there are broken units, the print will be affected by the uneven lighting. Furthermore, the light intensity at the joints is not so consistent with other areas, which will also influence the printing effect.

Different from Parallel Emission, new generation Integral Light Source is based on the reflection and refraction working principles. Five LED units with four emission chips for each ensure 90% and above evenness with 6000uw/cm² lighting intensity. It doesn’t matter even if a LED unit is broken, providing a more stable printing condition for users.

According to the testing statistics, the lighting evenness of the new generation Integral Light Source can reach up to 93.5%, while the Parallel Emission only 51.1%. Such remarkable evenness is quite reliable to print precision model with great glossiness.

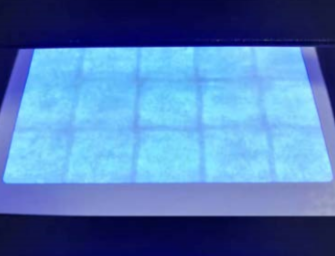

Lighting Evenness Differences (Visual Comparison)

| Parallel Emission | Integral Light Source |

| AVE:7496 MAX:8965 MIN:4578 EVENNESS: 51.1% |

AVE:3769 MAX:3869 MIN:3618 EVENNESS:93.5% |

|

|

|

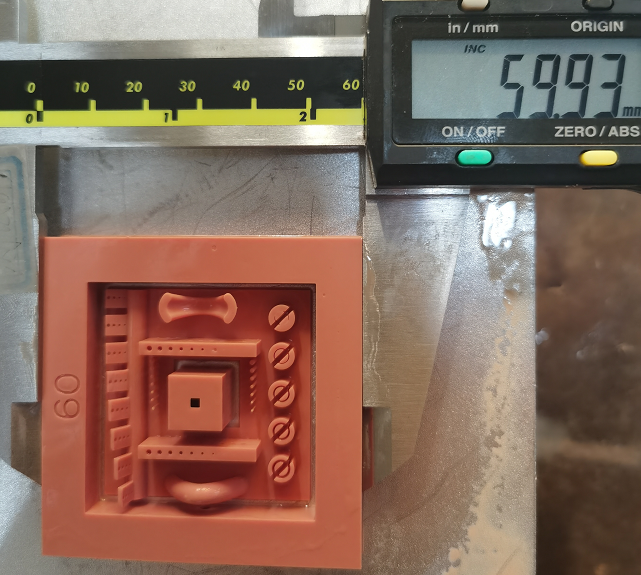

Accuracy

Resin 3D printers powered by the new generation Integral Light Source technology vastly improve the printing accuracy. Take the following T0 model as an example. To print a 60 x 60 mm model, the one printed with Integral Light Source Technology turns out to be 59.91 x 59.93 mm with the accuracy reaching 99.73%, more accurate than the one printed with Parallel Emission Technology.

| Integral Light Source Printing Technology | Parallel Emission Printing Technology |

|

|

|

| Target Print Size: 60 x 60 mm | Target Print Size: 60 x 60 mm |

| Actual Print Size: 59.91 x 59.93 mm | Actual Print Size: 59.78 x 59.78 mm |

| Accuracy: 99.73% | Accuracy: 99.27% |

The new generation Integral Light Source technology has been applied to products of Creality HALOT ONE series, including HALOT ONE, HALOT ONE PRO, and HALOT ONE PLUS. Let’s take a close look at HALOT-ONE PLUS. As a new resin 3D printer launched in 2022, HALOT-ONE PLUS will impress users with its high precision, intelligence and ease of use. Its 7.9'' 4K Mono LCD enables anime enthusiasts to print their favorite cartoon characters, tools, etc. Even micro-pores and micro-columns can be vividly printed, bringing imagination into reality with full details.

In addition to anime printing, the new generation Integral Light Source technology is favored by the jewelry industry. Up to 92% lighting evenness can perfectly print out micro-holders of 0.1-0.3 mm for models with complicated structures. High precision and enhanced speed vastly improve the 3D printing experience.

Powered by the new generation Integral Light Source technology, the HALOT-ONE series will surely bring some surprises. Anyone who is interested in it, why not print something and have fun?

Shop now: https://store.creality.com/products/halot-one-plus-resin-3d-printer