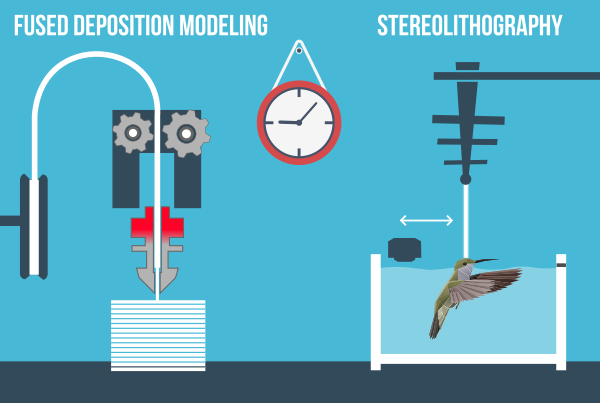

FDM VS SLA: The Differences to Be Clearly Explained

3D printing, also known as additive manufacturing, is a general technology based on digital model files, which uses powder-like metal or non-metal and other adhesive materials to build a model by layer printing. FDM (Fused deposition modeling) and SLA (Stereolithography) are the two most common 3D printing technologies on the market. As both technologies have a long development history, professionals or amateurs will generally choose these two technologies as entry-level choices when they contact 3D printers. Therefore, FDM and SLA are also the most mature 3D printing technologies at present.

No matter for prototype design, model display, or general parts manufacturing, although both of them can print out similar parts for users, many details still need to be paid attention to when how to select the most suitable 3D printer and material in the actual production. Let's compare the advantages and disadvantages of these two technologies and the situations in which they should be used.

The working principle of 3D printers based on FDM Technology is to extrude the melted thermoplastic onto the 3D printing platform, layer by layer until the final 3D model is finished. There are more kinds of 3D printer materials using FDM technology, from common ABS, PLA to composite materials doped with a variety of reinforced powders, which makes the FDM 3D printer used widely. At the same time, because FDM technology is open-source, fans can also customize 3D printers, so that they can change printing settings and hardware accessories according to different needs, so as to adapt to more special scenarios. The SLA 3D printer uses a UV laser or a light projector to continuously track each slice layer of an object, solidify the photosensitive resin into a hardened plastic until the final 3D model is finished.

FDM Technology Advantages

FDM 3D printer has a larger model size than the SLA printer. In addition to prototype design and printing of large-scale, practical parts and models, the FDM 3D printer also can apply to mall batch production. Single 3D printing material, generally has small resistance and friction, high strength as well as certain corrosion resistance. Composite materials generally refer to contain reinforced material powder or fiber mixtures, such as polycarbonate and carbon fiber, which can print out more solid, quality, and stable parts. FDM 3D printing range from the model display, small replacement parts of automobiles to fixtures of aerospace companies, making it a stronger choice for objects requiring mechanical functions and high performance. There are also some FDM 3d printers with high-precision, so that the surface of the printed parts is smooth and even, which can meet the general use and test requirements.

FDM Technology Disadvantages

The common FDM 3d printer sometimes will be little laminations also known as "whorl" on the model surface due to the low printing resolution. This requires additional polishing and grinding of the parts to achieve a smoother surface. In general, FDM 3D printing is also prone to temperature fluctuations, resulting in slower/faster cooling of thermoplastic filaments and surface delimitation. Common problems are faults and parts warping.

The 3D printer works by multiple internal components at the same time in the printing process. Any problems with the nozzle, extrusion, or hot end components can appear during the printing process. Therefore, when preparing and slicing 3D models, it is necessary to pay special attention to the printing settings. The setting of hardware and filament specifications also has some influence on 3D printing models.

SLA Technology Advantages

SLA 3D printing can achieve a resolution of at least 25 microns, so as to achieve smooth and meticulous surface. The surface details are incomparable to FDM, similar to the appearance of traditional injection molding. So SLA 3D is most suitable for product display or conceptual model making, organic structure, parts with complex geometry, figurines and other unique prototypes. The error of the SLA 3D printer is much smaller because UV laser is used as a data calibration part. As a result, it also has become an ideal choice for printing high-precision models, such as jewelry, medical implants, complex building models, and other small parts.

SLA Technology Disadvantages

Due to the brittleness of UV resin, only engineering SLA resin can be applied to parts under mechanical stress or cyclic load. In addition, most standard resins are well suited for models with a fine and smooth surface to display. At present, there is no SLA resin on the market compared with polycarbonate, nylon, or other FDM materials in terms of strength and mechanical properties. In addition, 3D printing resin has a higher cost and a much smaller model size. And they are not suitable for small batch production

How to Choose the Best Suitable Printer?

FDM and SLA have their own advantages and disadvantages, which can be used to print different models and combined them with multi-component assembly. SLA will be a better choice if you want to print a model with a fine surface to display. FDM will be more suitable for manufacturing from design, manufacturing to small-scale production.